steel structure buildings have an Achilles heel: poor fire resistance. In order to keep the strength and stiffness of the steel structure for a long time in the fire, and protect the safety of people’s life and property, a variety of fire protection measures are adopted in the actual project.

Why do steel structures that do not burn need fire protection?

Steel is a building material that does not burn. Compared with concrete, steel has many advantages such as earthquake resistance and bending resistance. Therefore, in modern buildings, steel structures are widely used, not only to relatively increase the load capacity of buildings, but also to meet the needs of architectural design aesthetic modeling, such as various single-story or multi-story factories, skyscrapers, warehouses, waiting rooms The hall is generally designed with steel structure.

Although steel will not burn, it will deform when exposed to high temperatures, resulting in structural collapse. As a building material, steel has some unavoidable defects in fire prevention.

Generally, the fire resistance limit of unprotected steel structures is about 15 minutes. Usually, at a temperature of 450~650C, the bearing capacity will be lost, and great deformation will occur, resulting in the bending of steel columns, steel beams and even structural collapse.

Further Reading: Steel Structure Installation & Design

Fire protection measures for steel structures

According to different fire prevention principles, the fire protection measures for steel structures are divided into heat resistance methods and water cooling methods.

heat resistance methods

The heat resistance method can be divided into the spray method and the encapsulation method.

Spraying method

Generally, fire retardant coating is used to coat or spray on the steel surface to form a fire-resistant and heat-insulating protective layer and improve the fire resistance limit of the steel structure.

This method is easy to construct, light in weight, long in fire resistance, and not limited by the geometry of steel components. It has good economy and practicability and is widely used.

There are many varieties of fire-resistant coatings for steel structures, which are roughly divided into two categories: one is thin-coating type fire-retardant coatings (type B), that is, intumescent fire-retardant materials for steel structures; the other is thick-coating type coatings (H).

Class B fire retardant coatings, the coating thickness is generally 2-7mm. The base material is organic resin, which has a certain decorative effect, and expands and thickens at high temperatures. The fire resistance limit can reach 0.5~1.5h.

The thin-coated steel structure fireproof coating has a thin coating, is lightweight, and has good vibration resistance. For indoor exposed steel structures and light-duty roof steel structures, when the fire resistance limit is specified to be 1.5h and below, thin-coated steel structure fireproof coatings should be used.

The thickness of the H class fire retardant coating is generally 8~50mm. Granular surface. The main component is inorganic thermal insulation material, with low density and low thermal conductivity.

The fire resistance limit can reach 0.5~3.0h. Thick-coated steel structure fireproof coatings are generally non-combustible, anti-aging, and more durable. For indoor concealed steel structures, high-rise all-steel structures and multi-story workshop steel structures, when the fire resistance limit is specified to be above 1.5h, thick-coated steel structure fireproof coatings should be used.

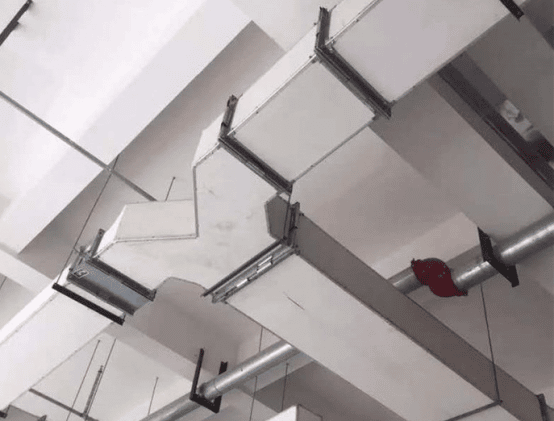

Encapsulation method

Hollow encapsulation method: Fireproof board or refractory brick is used to wrap the steel member along the outer boundary of the steel member. Most of the steel structure workshops in the domestic petrochemical industry use the method of building refractory bricks to wrap the steel components to protect the steel structure.

The advantages of this method are high strength and impact resistance, but the disadvantages are that it takes up a lot of space and the construction is more troublesome. Refractory lightweight boards such as fiber-reinforced cement boards, gypsum boards, vermiculite boards, etc. used as fireproof outer layers.

The method of box-wrapping large steel components has the advantages of flat and smooth decoration surface, low cost, small loss, no environmental pollution, aging resistance, etc., and has a good promotion prospect.

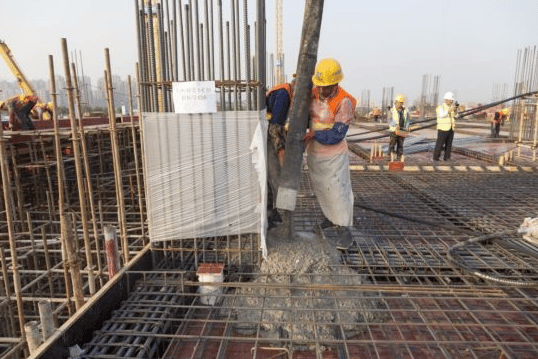

Solid encapsulation method: generally by pouring concrete, the steel members are wrapped and completely closed. The advantages are high strength and impact resistance, but the disadvantages are that the concrete protective layer occupies a large space and the construction is troublesome, especially the construction on steel beams and diagonal braces is very difficult.

water cooling methods

The water cooling method includes water shower cooling method and water-filling cooling method.

Water shower cooling method

The water spray cooling method is to arrange an automatic or manual spray system on the upper part of the steel structure. When a fire occurs, the sprinkler system is activated to form a continuous water film on the surface of the steel structure. When the flame spreads to the surface of the steel structure, the water evaporates and takes away the heat, delaying the steel structure building to reach its limit temperature.

Water-filled cooling method

The water-filled cooling method is to fill the hollow steel member with water. Through the circulation of water in the steel structure, the heat of the steel itself is absorbed. Therefore, the steel structure can maintain a lower temperature in a fire, and will not lose its bearing capacity due to excessive heating. To prevent rust and freezing, add rust inhibitor and antifreeze to the water.

In general, the heat resistance method can slow down the speed of heat conduction to the structural components through the heat resistant material. The heat resistance method is more economical and practical, and it is widely used in practical projects.

Advantages and disadvantages of spraying method and encapsulation method in fire protection measures of steel structure

Fire resistance

In terms of fire resistance, the encapsulation method is better than the spray method. The fire resistance of encapsulation materials such as concrete and refractory bricks is better than that of ordinary fireproof coatings.

In addition, the fire resistance of the new fireproof board is also better than that of fireproof coatings. Its fire-resistance rating is significantly higher than that of steel structure fireproof and thermal insulation materials of the same thickness, and higher than that of intumescent fireproof coatings.

Durability

Since the encapsulation materials such as concrete have good durability, it is not easy to deteriorate in performance over time; and durability has always been a problem that steel structure fireproof coatings have not been able to solve.

Thin and ultra-thin fire retardant coatings based on organic components, whether used outdoors or indoors, may have problems such as decomposition, degradation, aging, etc.

Constructability

The spraying method for fire protection of steel structures is simple and easy to construct and can be constructed without complicated tools.

However, the construction quality of the spraying method of fire retardant coating is poor, and it is difficult to control the rust removal of the substrate, the coating thickness of the fire retardant coating and the humidity of the construction environment; the construction of the encapsulation method is more complicated, especially for diagonal braces and steel beams, but the construction Strong controllability and easy quality assurance.

The thickness of the encapsulation material can be varied more accurately to control the fire resistance limit.

Environmental protection

The spraying method pollutes the environment during construction, especially under the action of high temperatures, it can volatilize harmful gases. The encapsulation method has no toxic emissions in construction, normal use environment and high temperature of the fire, which is beneficial to environmental protection and personnel safety in a fire.

Economical

The spraying method has the advantages of simple construction, short construction period and low construction cost. However, the price of fire retardant coatings is high, and the maintenance costs are relatively high due to the shortcomings of coatings such as aging.

The construction cost of the encapsulation method is high, but the materials used are cheap and the maintenance cost is low. In general, the encapsulation method is more economical.

Learn More About Influences the Price/Cost of Steel Building

Applicability

The spraying method is not limited by the geometry of the components and is mostly used for the protection of beams, columns, floors, roofs and other components. It is especially suitable for fire protection of steel structures in light steel structures, grid structures and special-shaped steel structures.

The construction of the encapsulation method is complicated, especially for steel beams, diagonal braces and other components. The encapsulation method is generally used for columns, and the scope of application is not as wide as the spray method.

Occupied space

The fireproof paint used in the spraying method is small in volume, while the encapsulation materials used in the encapsulation method, such as concrete and fireproof bricks, will occupy space and reduce the usable space. And the quality of the encapsulation material is also large.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.