Steel structure stairs are popular because of their few fulcrums, high bearing capacity, many shapes, and high technical content. Moreover, it is not easily affected by structures such as columns and floors and is sturdy and durable.

The steel plate of the welded staircase is accurately welded after debugging, and the front and rear are consistent with the left and right after the pedal is installed. All materials and fittings are horizontal and vertical. There are many kinds of materials for welding stairs, including square tubes, round tubes, angle steel, channel steel, and an I-beam, and the shapes are also very diverse.

What are Steel Structure Stairs

Steel stairs are a product of the industrial age and were widely used in factories before. In recent decades, the emergence of many high-tech-style buildings is characterized by some aesthetic characteristics: a large number of industrial metal materials are used, and the structural components of the building are exposed.

These characteristics are reflected in many buildings, and the steel staircase is an important element that can express its characteristics. The outdoor steel staircase of the Centre Pompidou in Paris forms a perfect combination with the scaffolding-like building facade.

Advantages of steel structure stairs

- It occupies a small area.

- The beauty of the shape. Steel stairs are available in U-shaped corners, 90-degree right angles, S-shaped, 360-degree spirals, and 180-degree spirals, with various shapes and graceful lines.

- It is practical. The steel-wood structure adopts cast steel pipe fittings, and there are various steel skeletons such as seamless steel pipe and flat steel.

- The colors are bright. There are various surface treatment processes for steel stairs, which can be fully automatic electrostatic powder spraying (ie, plastic spraying), or fully galvanized or fully painted, which is beautiful and durable. Suitable for indoor or outdoor use. It can reflect the modernist steel structure architectural art.

Steel Stairs Design

Stairs are passages that allow people to go up and down two spaces smoothly. It must have a reasonable structure design. According to the standard, each step of the stairs should be 15 cm high and 28 cm wide; the designer is required to have a thorough understanding and mastery of the size, in order to make the design of the stairs easy to walk and take up the least space.

- According to the actual situation, the height of the stair steps should be less than 18 cm and the width should be greater than 22 cm.

- From the perspective of architectural art and aesthetics, the staircase is the focus of vision and a highlight of the owner’s personality.

- When we choose a house, the size of the space and the height of the floor is already fixed, and it is difficult to change.

- For the convenience and comfort of going up and down the stairs, the stairs need a reasonable slope. The slope of the stairs is too steep and it is inconvenient to walk, which will bring people a “dangerous” feeling. If it is easy to go up the stairs, there needs to be a certain space for the stairs to extend.

- The use of steel stairs in the residence mainly solves the problem of small space inside the building. In a house designed by a Japanese architect, a steel staircase is designed on the side of the street.

- The stairs are filled with empty step grid steel plates, and the stepped stair beams on one side are very industrial.

- The building looks very industrial. form a structural logical relationship.

- In a steel staircase inside a building in Europe, the sloping slope is made of square steel as a whole, and the surrounding building components are also made of the same material.

- The composition of the lines and the proportional relationship have become the focus of the interior design of the space.

Further Reading: Steel Structure Installation & Design

The practice of steel structure stairs:

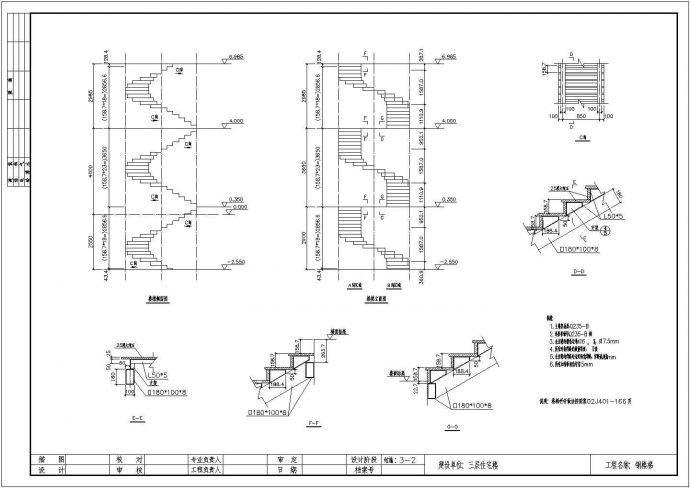

Determine the size of the stairs

- Determine the number of steps n on each floor according to the floor height h and the initially selected step height h, n=h/h.

- The horizontal projection length L of the flight is determined according to the number of steps N and the initially selected step width b, L=(0.5n-1)·b.

- Determine whether to set the ladder axis. For safety reasons, children’s stairwells should not exceed 120mm.

- Determine the width of the stair section according to the net width of the stairwell and the width C of the stairwell, a=(a-C)/2.

- According to the width D1 ≥ a) of the intermediate platform (D1), the width D2 of the floor platform (D2>a), and the horizontal projection length L of the ladder, check the net length B of the stair depth, D1+L+D2=B. If not, adjust the L value (ie adjust the B value).

Design adjustments.

If the interior structure is found to be inconsistent with the design drawings before construction, adjustments should be made according to the existing actual situation to determine the safety and practicability of the rigid frame staircase.

Prepare materials.

Various profiles and construction tools needed to make steel-frame stairs should be prepared in advance. And we cannot prepare suitable production materials. We should buy some sporadic materials to spare.

Start construction.

According to the design drawing of the attic steel frame staircase, the important fulcrum points are marked and laid out on site, and the size of the embedded parts is determined.

First deal with uneven walls and sundries.

Drill and clean the holes where marked. After the inspection is qualified, the bolts of the steel frame stairs are implanted, and the bolts are fixed in the holes with chemical fixatives.

Installation.

Drill holes on the embedded steel plate and channel steel according to the bolt positions, and then install the steel plate. After the steel plate is installed, certain anti-rust treatment should be carried out, and anti-rust protective paint can be brushed.

Then trim the steel plate of the steel staircase to their liking to make it look more beautiful and elegant. After all, the work is done, remove some glue and paint from the surface and clean if necessary. Such a rigid staircase will be installed.

Precautions for indoor construction of structural stairs

In order to avoid the illusion when going up and down the stairs, the height of the first step and the last step of the stairs should be the same as the other steps.

The height of the highest step of the stairs to the ceiling needs to have a clearance of more than two meters, and the minimum is not less than 1.8 meters. Otherwise, there will be pressure.

The distance between the railings

Between the centers of the two railings is preferably 8 cm, not more than 12.5 cm, so as to prevent children from sticking their heads out of the gap.

The height of the armrest

waist position is 85~90 cm, and the diameter of the armrest should be 5.5 cm.

The height and depth of the steps

the height of the steps should be 15-18 cm, and the depth of the steps should be 22-27 cm. The number of steps is about 15 steps. If it is too high, you may need to set up a stair rest platform.

Stair width:

when one side is empty, the net width is not less than 75 cm; when there are walls on both sides, the net width is not less than 90 cm.

Safety

Stair parts should be smooth and round, without protruding and sharp parts. For families with children and elderly people, the slope of the stairs should be slow and the rotation angle should not be too large; the stair treads should take anti-skid measures, such as anti-skid strips, anti-skid pads, anti-skid grooves, etc.

Stair lighting

Too dark light is not conducive to walking safety, and too bright light is prone to glare. Therefore, the light on the stairs should be soft and clear.

Staircase style

The staircase design should be consistent with the decoration style.

Stair noise problem

It is related to the connection of the various parts of the pedal, and it should not produce excessive noise during use, so as not to affect the rest of the family members.

Further Reading: Steel Building Plans and Specifications

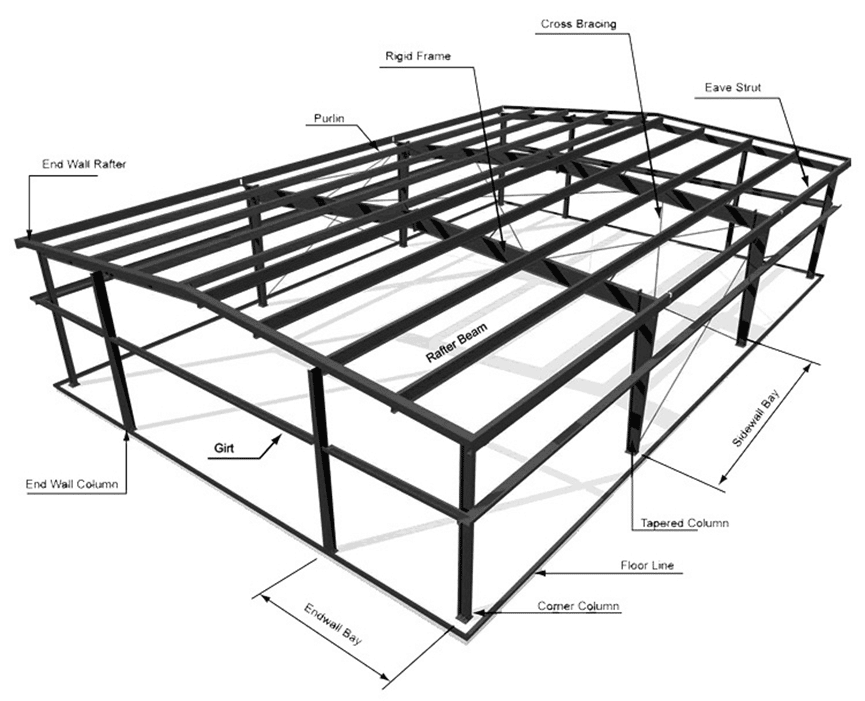

The PEB Steel Building

The Other Additional Attachments

Building FAQs

- How to Design Steel Building Components & Parts

- How Much Does a Steel Building Cost

- Pre-Construction Services

- What is a Steel Portal Framed Construction

- How to Read Structural Steel Drawings

Blogs Selected for You

- The Main Factors Affecting The Cost of Steel Structure Warehouse

- How Steel Buildings Help Reduce Environmental Impact

- How to Read Structural Steel Drawings

- Are Metal Buildings Cheaper Than Wood Buildings?

- Benefits of Metal Buildings For Agricultural Use

- Choosing the Right Location For Your Metal Building

- Making a Prefab Steel Church

- Passive Housing & Metal –Made for Each Other

- Uses for Metal Structures You May Not Have Known

- Why Do You Need a Prefabricated Home

- What Do You Need To Know Before Designing a Steel Structure Workshop?

- Why Should You Choose a Steel Frame Home Over a Wooden Frame Home

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.