What Is Pre Engineered Metal Building?

By definition, the pre-engineered metal building is a building system designed to be built and custom positioned for the intended use and the customization added by the owner. Much of the labor to construct the building is designed outside of the structure, as major connections that typically require field welding and voids for doors, windows, and other components are pre-punched prior to delivery.

Value for Money

The structure of metal building accounts for approximately 10-15% of the total construction cost. Obviously, choosing the right infrastructure is critical in a competitive market. Studies have found that steel structure solutions can reduce the structural cost of a building by up to 6% compared to using concrete framed buildings, which can save you significant amounts of money.

Fast Construction

Steel construction involves prefabricated components that are fabricated on-site and can be installed quickly on-site with little or no problems. This allows for an earlier return on investment and other time-related savings, which can have an excellent impact on profitability.

Flexibility and Adaptability

Structural steel beams with web openings allow for open designs with fewer columns and effective circulation space. This results in a building with a malleable mass and allows all interior walls and fixtures to be replaced if necessary. The metal buildings have the potential to be used for a variety of purposes.

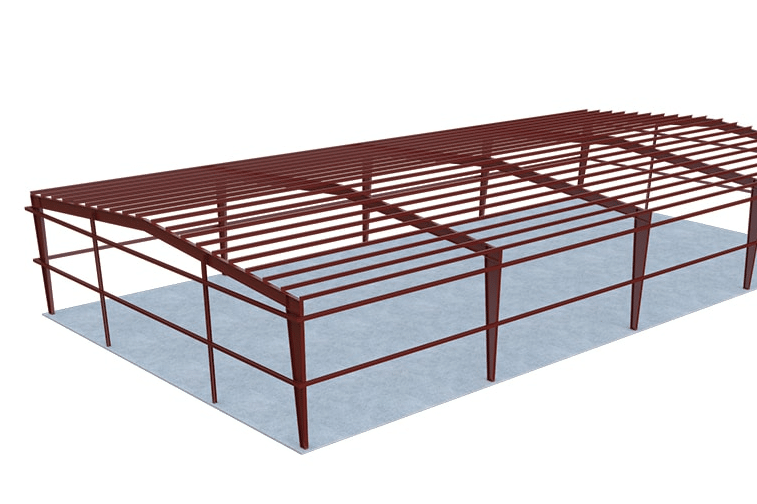

popular 3D metal building design

The most versatile sizes that can be customized for any conceivable application.

View All 3D Building Renderings >

Blogs Selected for You

No matter where you are in the build process, we have the resources, tools, and guidance to ensure your project is a true success.

View All Blogs >

Contact Us

Have questions or need help? Use the form to reach out and we will be in touch with you as quickly as possible.