As the first choice for temporary housing, steel structure buildings are very common on construction sites. The reason why steel structures are so popular, is not only because the construction cost of steel structures is low, but also because the construction period of steel structures is very short, so how long is the construction period of steel structure installation in general?

The overall construction process of general steel structures is generally divided into three parts, namely the steel structure’ construction preparation stage, the construction stage, and the delivery acceptance stage.

Among them, the preparation stage is also relatively cumbersome, mainly requiring the implementation of the required materials, personnel, venues, tools, etc., so as to ensure that the construction can be completed more efficiently and faster. The construction stage includes material inspection, progress quality control, contract visa, payment progress, etc.

These are the construction stages of the steel structure. There is no exact time for the construction period of the steel structure because the area of the steel structure is different. Different building designs, different numbers of floors, and different numbers of construction workers will all affect its construction time.

Further Reading: Steel Building Plans and Specifications

The Main Factors affecting

The problems encountered in the construction of metal building kits are diverse and complex. Moreover, in view of the quality problems encountered during the processing and installation of the grid structure, the engineer of the heavy-duty steel structure has summarized five factors for everyone. The fundamental concept focuses on key factors such as people, objects, machines, laws, and the environment.

Workers

People can be said to be the main body of all quality activities, generally referring to units, organizations, or individuals that use grid steel structure projects, including construction, monitoring, survey and design, consulting, and other service units.

Materials

Material control includes the control of raw materials, components, finished products, and semi-finished products, strictly controlling quality acceptance, must ensure the accurate and proper use of materials, and implementing technical management at the receiving and other connections after compiling management accounts to avoid materials and materials. mixing, scheduling, storage, and transportation.

Mechanical Equipment

The selection of steel structure construction machinery and equipment should not only consider site conditions, construction site types, mechanical equipment performance, and other factors but also discuss and compare construction technology and construction organization economy in combination with various influencing factors such as construction technology and management methods. Get better economic benefits.

Process Method

During the construction period, the technical arrangement, technological process, organization and implementation, processing and testing procedures, and design organization of the steel plant belong to the category of technological methods.

Environment

There are many environmental factors that affect the quality of grid construction, including engineering environmental factors. Heavy steel structure engineers emphasize here: that the impact of environmental factors on quality is complex and changeable. Effective measures must be taken with reference to the characteristics and specific conditions of the project. Especially at the construction site, creating a civilized construction production environment, keeping the materials and workpieces in good condition at all times, improving the construction quality, and sanitation and cleanliness of the construction area are good prerequisites for quality and safety.

What are the precautions for the construction of steel building

If there is a gutter during the installation of the steel structure, the tie rod cannot be designed to be close to the top of the column, otherwise, it may lead to the failure to install the downspout. In addition, the position of the gutter downpipe, the tie rod, and the inter-column support must be considered well, otherwise, it will either hit the tie rod or the inter-column support.

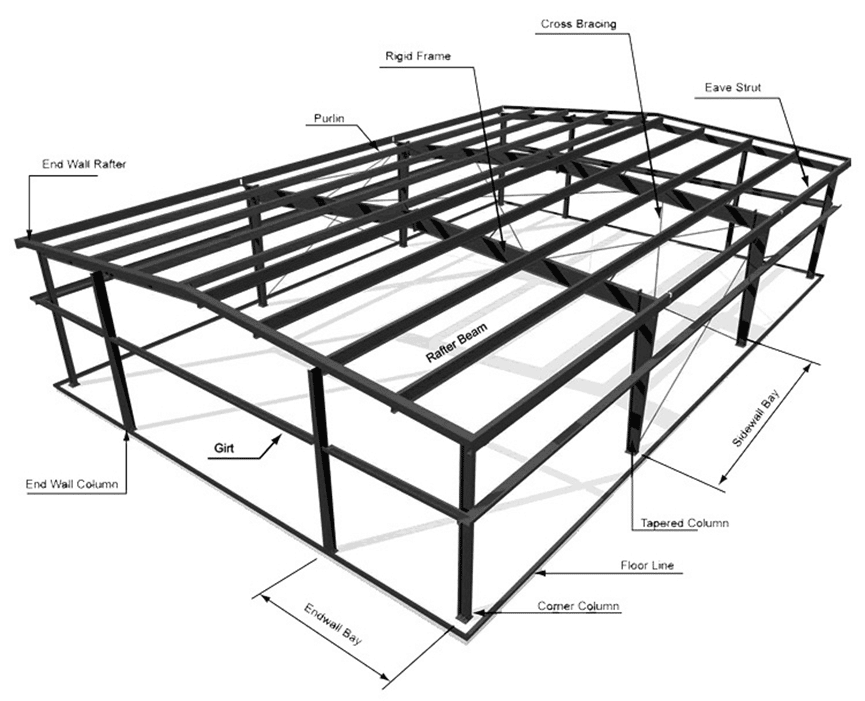

The arrangement of the bolts on the horizontal support should be reasonable and should not deviate too much from the main beam. It is suggested that the convenience of the installation of the steel structure should be considered. Otherwise, workers must lean out to tighten the turnbuckle bolts or use a ladder to go up during the installation of the steel structure, or it is very unsafe to climb up the purlins and tighten the turnbuckles after the purlin installation is complete. In addition, consider the location of the corner braces, and do not fight with the corner braces when arranging the horizontal braces.

Don’t unilaterally consider factors such as “pulled edge and compressed edge” on the purlin’s bracing hole, and punch out holes with different upper and lower margins, because it is easy to install the steel structure backward, and the result is unfavorable.

the corner panels of doors and windows cannot be generalized, because you cannot guarantee that the panels are located at the crest or trough of the profiled plate during construction.

When doing large-scale projects, the numbering of the deepening drawings must take into account the convenience of production, delivery, and installation.

metal building installation

Generally, a single-layer steel structure needs to be used as a foundation before installation. The types of foundations include strip foundation, raft foundation, pile foundation, etc., and the screw or pre-embedded parts should be pre-embedded on the foundation in advance. Just hoist it directly.

Further Reading: Steel Structure Installation & Design

Taking the steel structure workshop as an example, the hoisting adopts the principle of “first middle, then outside, column first, then beam, first down and then up”. A stable frame system is first formed in the middle part of the workshop, and then it is advanced and symmetrical to both ends. Install the remaining steel columns and beams in the following order:

The process of Installation

- Re-measurement of anchor bolts

- Unloading of steel components

- Incoming inspection of components

- Direct hoisting of automobile cranes in place

- Temporary tightening of anchor bolts

- Temporary tie of cables and wind ropes

- Adjustment of axis position and verticality of steel columns

- Steel stud bolts and Fastening and welding of the column foot pressure plate

- Installation of the next steel column

- Installation of tie rods between steel columns

- Formation of the first stable lattice system

- Steel roof truss ground assembled into a whole and lifted into place by two machines to form the first steel roof truss

- Symmetrical installation of columns and roof trusses on both sides

- The installation of the steel structure is completed, and the structural acceptance extension information

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.