Prefabricated shop buildings are composed of steel as the skeleton of the building and a new type of thermal insulation steel skeleton light plate as the enclosure structure, the steel frame light plate is produced and installed in the factory, it only needs to transport the plate to the construction site and connect it with welding and bolts.

Learn More About Influences the Price/Cost of Steel Building

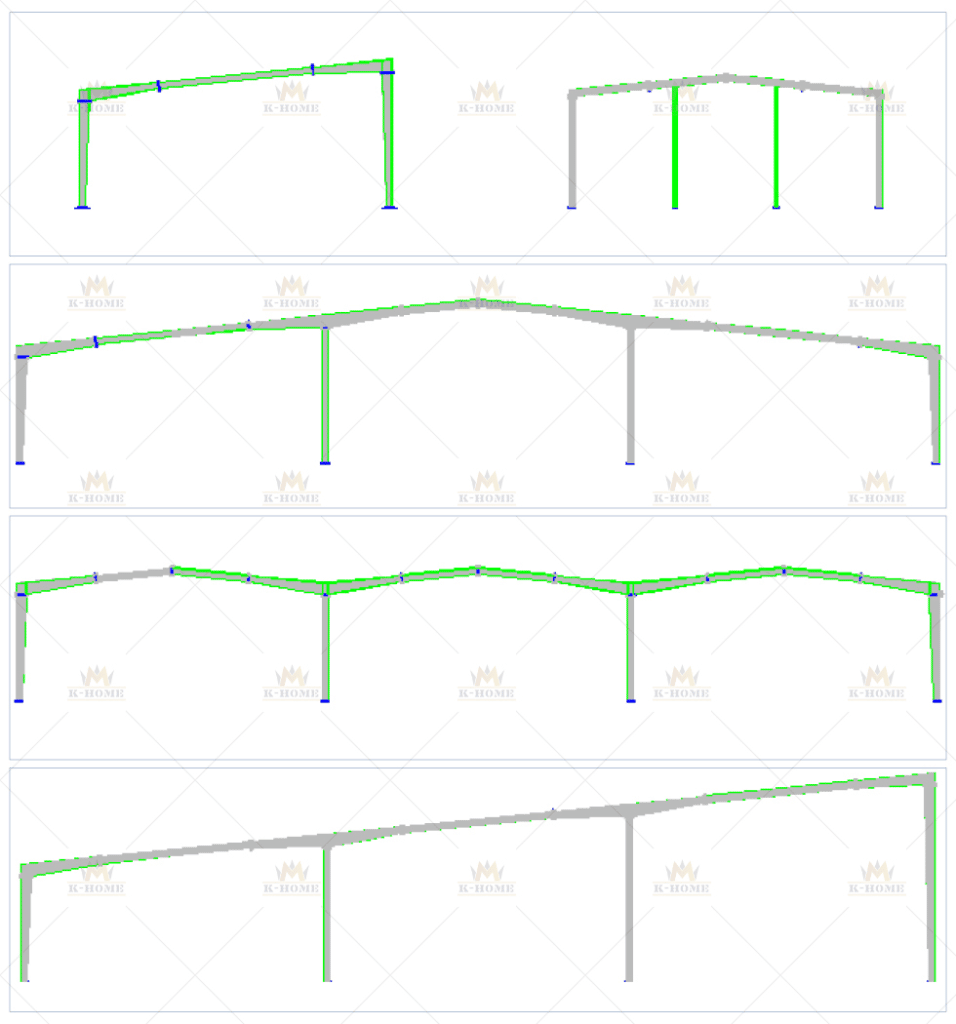

Metal Shop Buildings Design

The first task is to be familiar with the drawings as a whole, carefully read and understand the architectural design instructions and structural design instructions, and summarize the relevant information that you think you need to know in the process of calculation.

For example material specifications and models of roof panels, wall panels, gutter, main Material and material of steel frame, crane beam, purlin, etc., as well as steel surface treatment requirements, etc.

Due to the different materials used by different manufacturers and different quotation methods, the prices of steel shop buildings are also very different.

Further Reading: Steel Structure Installation & Design

Span and Height

A metal shop building with a span of 15 meters is a watershed. Greater than 15 meters, the cost per unit area will decrease with the increase of the span, but if the span is less than 15 meters the span is reduced, and the cost per unit area will increase instead.

The standard height of the steel structure is generally 6-8 meters. The increase in height will affect the safety of the structure, so the amount of steel used in the steel structure will also increase, which will ultimately affect the cost of the entire metal shop building.

Material Fee

The material of metal shop buildings is mainly steel, and its price is relatively stable.

Recommend Reading: Steel Raw Materials Price

Labor Cost

The labor cost of metal shop building construction, generally a simple single-story steel warehouse construction time is about 3 months, and the labor needs 20 people. According to the average monthly salary of each person, the corresponding cost can be calculated.

Other Factor

Technical and project costs are included. The process cost includes preliminary design and drawing, which many manufacturers do not consider, but the detailed design will reduce the waste of the later construction process.

Further Reading

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.