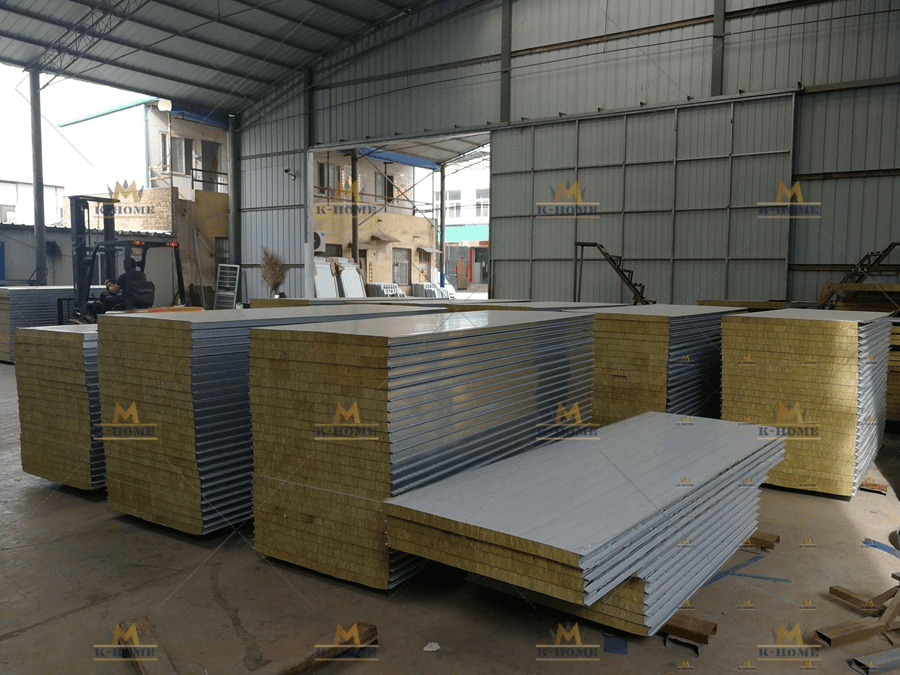

Rock Wool Sandwich Panel is a type of sandwich panel. Sandwich panel refers to a three-layer structure, with galvanized steel plates on both sides, and rock wool sandwich material in the middle. Rock wool is mainly made of basalt as the main raw material, and is an inorganic fiberboard processed by high-temperature melting. Quantity in June 1981 The rock wool board is a new type of thermal insulation, flame insulation and sound absorption material.

Rock wool insulation is based on selected high-quality basalt as the main raw material. After the acquired melting, the international advanced four-roll centrifugal cotton production process is used to pull the basalt wool high-temperature solution into discontinuous fibers of 4~7m, and then A certain amount of binder, water repellent, and dust removal oil is added to the rock wool fiber, and through sedimentation, curing, cutting and other processes, a series of products with different densities are made according to different uses.

Moreover, basalt is non-toxic and has almost zero radiation. It is a relatively good chemical raw material and building decoration building material and it is also a widely used material.

Further Reading: Steel Structure Installation & Design

Fireproof features

The raw material of the outer wall rock wool board is natural volcanic rock, which is a non-combustible building material fireproof material. Main fire protection characteristics:

Heat Insulation

The outer wall rock wool board fiber is slender and flexible, and the content of the slag ball is low. Therefore, the thermal conductivity is low, and it has an excellent thermal insulation effect.

Sound absorption and noise reduction

Rock wool is an ideal sound insulation material, and a large number of slender fibers form a porous connection structure, which determines that rock wool is an excellent sound absorption and noise reduction material.

Hydrophobicity

The water repellency rate of hydrophobic rock wool products can reach 99.9%; the water absorption rate is extremely low, and there is no capillary penetration.

Moisture Resistance

In an environment with high relative humidity, the volume moisture absorption rate of rock wool is less than 0.2%. According to ASTMC1104 or ASTM1104M method, the mass moisture absorption rate is less than 0.3%.

Non-Corrosive

Rock wool is chemically stable, with a PH value of 7-8, neutral or weakly alkaline, and is suitable for carbon steel, stainless steel,

Metal materials such as aluminum are non-corrosive.

Safety and environmental protection

Rock wool has been tested and does not contain asbestos, CFC, HFC, HCFC and other substances harmful to the environment. Will not be corroded or produce mildew and bacteria. (Rock wool has been identified as a non-carcinogenic substance by the International Agency for Research on Cancer)

Precautions

- Pay attention to rain protection and do not work in rainy days.

- When cutting, try to keep the steel strip on one side, so that the wall panel can be better supported and more stable after construction.

Application

In prefab house fields, the rock wool sandwich panel is widely used for wall panels and roof panels. Let’s see its application below

The PEB Steel Building

The Other Additional Attachments

Building FAQs

- How to Design Steel Building Components & Parts

- How Much Does a Steel Building Cost

- Pre-Construction Services

- What is a Steel Portal Framed Construction

- How to Read Structural Steel Drawings

Blogs Selected for You

- The Main Factors Affecting The Cost of Steel Structure Warehouse

- How Steel Buildings Help Reduce Environmental Impact

- How to Read Structural Steel Drawings

- Are Metal Buildings Cheaper Than Wood Buildings?

- Benefits of Metal Buildings For Agricultural Use

- Choosing the Right Location For Your Metal Building

- Making a Prefab Steel Church

- Passive Housing & Metal –Made for Each Other

- Uses for Metal Structures You May Not Have Known

- Why Do You Need a Prefabricated Home

- What Do You Need To Know Before Designing a Steel Structure Workshop?

- Why Should You Choose a Steel Frame Home Over a Wooden Frame Home

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.