customized steel workshop kits for Global standard certification

Prefabricated steel workshop kits are an efficient and cost-effective alternative to traditional workshop buildings. K-HOME offers customized steel workshop kits, manufactured in strict compliance with China’s GB standards and with international adaptability.

For overseas projects, K-HOME has a professional engineering team versed in various international standards, including American Standards (ASTM) and European Standards (EN). We conduct precise structural review and calculations based on local building regulations, ensuring that each project fully complies with local standards for safety and compliance.

Notably, we offer an innovative integrated crane and steel structure solution. K-HOME is involved in crane selection and design from the initial stages of the project, seamlessly integrating the lifting equipment into the main structural design. Our in-depth understanding of crane technical parameters allows us to incorporate cranes into the steel workshop design from the initial stages. This integrated design avoids equipment operational conflicts inherent in the traditional “design-build” model, while achieving highly coordinated structural and equipment systems.

As an industry-leading steel structure service provider, K-HOME leverages its years of expertise to provide comprehensive, one-stop services from design, manufacturing, to installation. Our independently developed intelligent design system integrates a multi-year project database. For common projects like industrial plants and warehouses, we can combine local geological and climate data to generate a compliant design plan and detailed quote within 5 minutes. For personalized needs, our experienced design team will conduct in-depth analysis and provide customized solutions that balance functionality and cost-effectiveness. We also provide continuous technical support throughout the project implementation cycle, ensuring precise implementation from blueprint to completion.

Essential Components of Steel Workshop building Kits

The primary structure of the steel workshop building consists of steel columns, steel beams, and steel roof trusses. These primary components are reliably connected through welding or high-strength bolts, forming a strong and stable spatial structure.

The secondary structure, also known as the support system, primarily includes purlins, column braces, horizontal braces, and corner braces. These components work in conjunction with the primary structure to effectively transfer longitudinal and transverse loads, enhancing the building’s overall rigidity and lateral resistance, and ensuring structural safety under wind, earthquake, and other forces.

The exterior walls and roofing system form the building’s envelope and are generally constructed from lightweight, high-strength color-coated steel plates. In areas with high thermal insulation requirements, materials such as insulated sandwich panels can also be used to meet thermal performance requirements. This type of enclosure material not only offers excellent waterproof and fire resistance but also offers the advantages of easy and economical construction.

wall system wall system roof system roof system

The foundation, as the foundation of the factory building structure, bears all loads from the superstructure and safely transfers them to the substructure. Since steel structures are light in weight but sensitive to uneven settlement, foundation design must be carried out based on detailed geological survey data, fully considering foundation conditions to ensure that the foundation form matches the foundation bearing capacity and ensure the safety and durability of the overall structure.

buy direct from the manufacturer | k-hOME

Before selecting a prefabricated steel frame workshop manufacturer, it’s important to thoroughly research and consider factors such as the company’s reputation, experience, the quality of materials used, customization options, and customer reviews. Additionally, obtaining quotes and consulting with representatives from these companies can help you make an informed decision based on your specific project requirements.

K-HOME offers prefabricated steel buildings for various applications. We provide design flexibility and customization.

Features Steel Structure Workshop kits

Steel workshop kits offer numerous advantages, which is why more and more business owners are choosing prefabricated steel buildings. This building system is an excellent choice for businesses seeking maximum functionality and cost-effectiveness.

- Durability: The greatest advantage of steel workshop kits is their durability. Steel’s inherent high strength enables steel structure workshops to easily withstand extreme weather, heavy loads, and frequent use. They offer excellent earthquake and wind resistance, and their fire resistance rating can be enhanced with the use of fire-retardant coatings. This inherent strength ensures the building’s long-term durability and operational safety.

- Affordability and Cost Control: While the initial investment in a steel workshop kit may be slightly higher than that of traditional buildings, it is a more economical option over its entire lifecycle. First, prefabrication reduces material waste. Second, steel structure construction takes a shorter time, reducing labor costs. Finally, compared to traditional buildings, steel structure workshops require virtually no maintenance, minimizing ongoing maintenance costs.

- Flexible Layout: Steel workshop kits can be manufactured to your desired size and offer flexible designs. Widths up to 30 meters can be designed as open, column-free, barrier-free spaces, perfectly adapting to changing production line and layout requirements.

- Short Construction Period: Prefabricated steel workshop components are precisely manufactured in the factory, with only efficient on-site assembly required. This significantly shortens the construction period. This means your Steel Workshop Building project can be put into production sooner, accelerating return on investment and significantly reducing the risk of delays due to factors such as weather.

- Sustainability: Steel structure buildings are recognized as an environmentally friendly choice. Steel is 100% recyclable, prefabrication produces minimal construction waste, and energy consumption is significantly lower than concrete buildings.

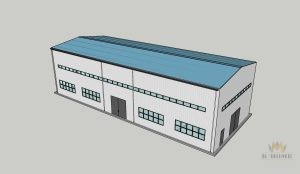

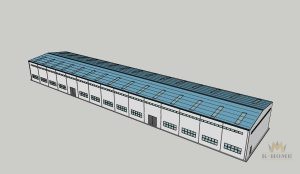

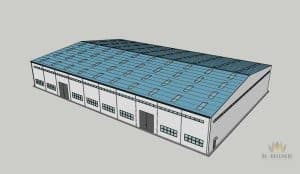

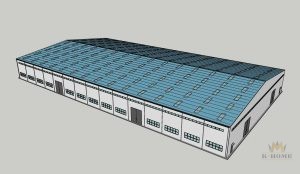

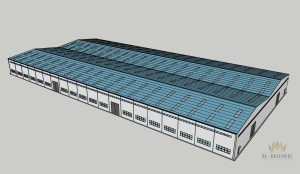

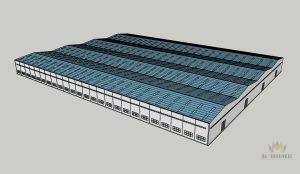

Most Popular steel frame workshop kits design plans

As a professional manufacturer with 20 years of experience in the steel structure industry, we provide extensive services to the global infrastructure market in high-wind coastal areas, high-altitude permafrost zones, and earthquake-prone regions. To address the extreme environmental challenges faced by different regions, we strictly adhere to international standards and independently develop an environmentally adaptable structural database. In complex geographical environments, we ensure the stability and durability of our steel structures through meticulous design. For example, unstable foundations are a common challenge in mountainous or coastal areas. We utilize high-strength steel and modular technology to optimize foundation support and reduce the risk of subsidence. In Southeast Asia, where steel is susceptible to corrosion in high-temperature and high-humidity environments, we incorporate anti-corrosion coatings to meet local environmental standards and extend the life of the structure.

The following designs represent common steel workshop kit dimensions, carefully designed for safety and cost-effectiveness.

steel frame workshop kits cost

Price is one of the most important considerations for every business owner when planning a project. It’s important to note that the price of steel structure projects is not fixed. Due to its diversity and complexity, costs are affected by a combination of variables. As a professional steel structure building contractor, K-HOME is committed to providing clients with safe, reliable, and cost-effective steel structure solutions, ensuring that every quote is reasonable and transparent.

The main factors affecting the cost of steel structure projects include:

- Project scale and complexity: The project’s size, structural form, and technical difficulty directly impact resource investment. Larger and more complex structures require more materials, manpower, and construction time, significantly impacting the overall cost.

- Material selection: Steel type, connectors, maintenance systems, and the grade and brand of anti-corrosion coatings are significant components of the cost. K-HOME assists clients in selecting the most cost-effective material solution while ensuring structural safety.

- Construction time: Projects with tight deadlines may require accelerated prefabrication, additional teams, or parallel operations, all of which incur additional resource coordination and management costs. 4. Project Location: Regional labor costs, logistics costs, and on-site environmental conditions (such as wind and rain, and seismic requirements) will also impact the final price.

K-HOME, with its professional design and construction team, provides integrated steel structure engineering services, from pre-planning, structural design, prefabrication, on-site installation, to ongoing maintenance. Through scientific management and efficient execution, we strive to deliver high-quality, long-lasting steel structures to our clients while controlling costs.

why K-HOME Steel building?

As a professional PEB manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.