Prefabricated Steel structure Wholesale Supermarket

steel structure supermarket / steel building supermarket / retail metal building / Retail Steel Building Kits / Commercial Retail Building Solutions

Wholesale supermarkets are a highly representative example of steel-framed commercial buildings. Compared to traditional building forms, steel structures perfectly meet the design requirements of large commercial spaces, which often necessitate wide bays and flexible partitioning.

Steel structure buildings are particularly well-suited for high-traffic locations such as large wholesale supermarkets and wet markets. Their superior spans and spatial performance easily create spacious shopping spaces. Furthermore, the industrialized production of prefabricated components ensures precision and efficiency, while the ease and speed of on-site installation significantly shortens the construction cycle.

Steel structure buildings, with their rapid construction and efficient use, are an ideal choice for rapidly commissioning supermarket-style commercial projects, perfectly balancing the dual demands of construction speed and operational efficiency.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

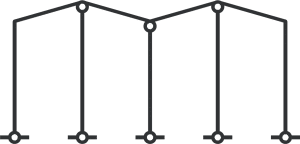

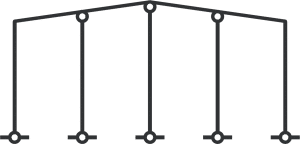

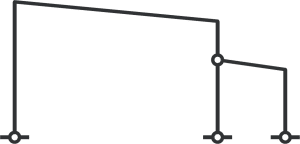

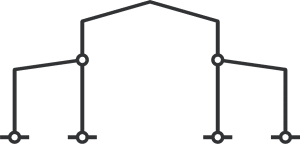

Prefab steel structure Types

At K-HOME, we understand that prefabricated steel structure buildings come in various shapes and sizes, and the possibilities for customization are endless. As such, we offer customized solutions that can meet the unique needs of businesses and individuals.

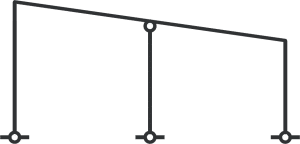

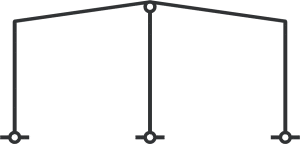

Single-span Overhanging Eaves Single-span Double-sloped Roofs Multi-span Multi Double-sloped Roofs Multi-span Double-sloped Roofs High-low Span Single-sloped Roofs High-low Span Double-sloped Roofs Double-span Single-sloped Roofs Double-span Double-sloped Roofs

Technical specifications of the steel building supermarket

| Component Structure | Material | Technical Parameters |

|---|---|---|

| Main Steel Structure | GJ / Q355B Steel | H-beam, Customized height according to building requirements |

| Secondary Steel Structure | Q235B; Paint or Hot Dip Gavalnized | H-beam, Spans range from 10 to 50 meters, depending on design |

| Roof System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to design |

| Wall System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to wall area |

| Window & Door | Color steel sliding door / electric rolling door Sliding Window | Door and window sizes are customized according to design |

| Fireproof Layer | Fire retardant coatings | Coating thickness (1-3mm) depends on the fire rating requirements |

| Drainage System | Color Steel &PVC | Downspout: Φ110 PVC Pipe Water Gutter: Color Steel 250x160x0.6mm |

| Installation Bolt | Q235B Anchor Bolt | M30x1200 / M24x900 |

| Installation Bolt | High-Strength Bolt | 10.9M20*75 |

| Installation Bolt | Common Bolt | 4.8M20x55 / 4.8M12x35 |

Packaging and delivery of prefabricated steel structures

As we know, steel structure building has many parts, in order to make you clear and reduce the site work, we’ll mark each part with labels and take photos. In addition, we also have rich experience in packing. We will plan in advance the packing location of the parts and the maximum use space, as far as possible to reduce the number of packing for you, and reduce the cost of shipping.

You may be worried about the problem of unloading. We put an oil wire rope on each package of goods to ensure that after the customer receives the goods, they can directly pull the whole package of goods out of the box by pulling the oil wire rope, saving time, convenience and manpower!

Design Process of Steel Structure Buildings

As a professional steel structure manufacturer, K-HOME maintains a comprehensive and scientific design and delivery process to ensure each project is completed safely, with reliable quality and on-time delivery. Our designs strictly adhere to the national standard “Code for Design of Steel Structures” (GB50017-2017), integrating specific needs to provide clients with the most appropriate solutions.

First, we conduct detailed discussions with clients to understand project requirements and building environment factors, such as wind speed, rainfall, snowfall, and earthquake intensity. This information directly influences the design. Next, our designers develop a preliminary plan, determining the steel type, structural form, and dimensions. Force calculations are then performed according to the specifications to ensure structural stability and safety.

After the design is completed, our professional team conducts a rigorous review, checking the calculations and drawings to ensure compliance with specifications and construction requirements. Upon approval, we provide clients with a detailed quotation based on the design and material costs. This quotation includes all costs, including production, packaging, and shipping, ensuring a comprehensive understanding of costs.

Once the quotation is confirmed, we begin production, preparing relevant technical documentation and construction drawings to ensure precise manufacturing. Upon completion, the product is packaged according to standard specifications and prepared for shipment. Regarding ocean freight, K-home will coordinate container loading and transportation arrangements. We will promptly monitor logistics status and maintain communication with customers to ensure the safe and timely arrival of goods. Upon arrival, customers simply complete customs clearance and pick-up procedures in accordance with local regulations, ensuring a smooth and efficient process.

In addition, to help customers better understand product installation, we provide detailed installation videos and drawings. If customers require technical support, we can also dispatch engineers to assist on-site, ensuring a hassle-free installation.

In short, K-HOME not only prioritizes design and production quality, but also pays attention to every step, from quotation to logistics, striving to provide customers with comprehensive, high-quality services and build safe and durable steel structures.

Prefabricated steel structure manufacturer

Before selecting a prefabricated steel structure building manufacturer, it’s important to thoroughly research and consider factors such as the company’s reputation, experience, the quality of materials used, customization options, and customer reviews. Additionally, obtaining quotes and consulting with representatives from these companies can help you make an informed decision based on your specific project requirements.

K-HOME offers prefabricated steel buildings for various applications. We provide design flexibility and customization.

Frequently Asked Questions

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.