Industrial Metal Buildings

metal industrial buildings / industrial metal building kits / industrial metal building systems

What Are Industrial Metal Buildings?

Industrial metal buildings are essentially a construction method that employs high-strength steel as the principal structural material. Before being delivered to the location for quick assembly, these metal industrial buildings are either standardized or customized for prefabrication at factories. Unlike simple “prefabricated cabins,” they constitute a mature, durable, and completely conforming permanent or semi-permanent construction type. The basis of this technique rests in the integration of “prefabrication” and “on-site assembly,” where all key steel components—such as main beams, secondary beams, columns, and purlins—are premanufactured in a controlled factory environment, providing outstanding accuracy and quality consistency.

Compared to traditional brick-concrete or cast-in-place concrete buildings, the most notable feature of metal industrial buildings is the elimination of extensive and complex wet work. While they still require a solid foundation professionally designed and constructed (such as concrete isolated or strip foundations), the upper structure can be assembled at an extremely rapid pace. This construction method seamlessly combines the strength and durability of metal industrial buildings with the speed and cost-effectiveness of prefabricated construction, making it suitable for a wide range of industrial applications—from simple storage warehouses to complex manufacturing plants.

Why Choose Industrial Metal Buildings? (The Key Benefits)

Unparalleled durability and structural strength

The outstanding endurance of metal industrial buildings is the main factor in their selection.

The materials employed, such as hot-dip galvanized or high-strength steel, exhibit outstanding resistance to corrosion and rust, enabling them to endure the erosion of extreme weather conditions such as large loads, powerful winds, and a lot of snow, guaranteeing the building’s stability and safety during many years of operation.

Significant cost-effectiveness and rapid return on investment

Metal industrial buildings are quite cost-effective when considering lifespan costs. Prefabricated manufacture speeds up return on investment by drastically cutting labor costs and on-site building time, allowing projects to be finished and put to use sooner.

Because metal walls and roofs require very little maintenance, their construction costs are usually cheaper than those of conventional structures. Long-term heating and cooling energy consumption may be significantly decreased by integrating high-quality insulating materials into the building system, which further lowers operating expenses.

Flexible Design and Future Scalability

Industrial metal buildings are far from monotonous. They offer immense design flexibility, with nearly column-free interior spaces featuring clear spans, providing maximum freedom for equipment layout, production line arrangement, and logistics turnover. More importantly, their modular nature makes future expansion exceptionally simple. By extending the existing structure or adding bays, spatial expansion can be achieved with minimal cost and construction time, perfectly adapting to the growing needs of enterprises.

Exploring Your Design Options: Types of Industrial Metal Buildings

Main structural types: Clear span and multi-span design

Clear-span structures and multi-span structures are the two main structural design categories for industrial metal buildings. huge steel beams are used in clear-span design to create expansive interior spaces devoid of intermediary columns. This makes it especially appropriate for applications that call for the passage of huge equipment or open storage areas, such stadiums, airplane hangars, or enormous logistics warehouses.

In contrast, multi-span constructions accommodate buildings with bigger widths or more complicated layouts by including one or many rows of intermediate columns. This style is typically found in big manufacturing plants or industrial facilities with segregated usage, optimizing material usage and expense while permitting the development of broad areas.

- clear-span steel building

- Multi-span steel building

Improve Space Utilization: Mezzanine Design

To enhance the usage of vertical space, metal industrial buildings may readily include mezzanine designs. A mezzanine is an intermediary floor that is built into a building and is usually utilized for light manufacturing lines, offices, restrooms, or parts storage.

The steel frame offers a sturdy and secure support for the mezzanine, substantially increasing the useable space by 50% or more without enlarging the building’s footprint, considerably boosting spatial efficiency and functional variety.

Customized size and appearance

Industrial metal structures allow for almost complete customization of their size. It is possible to exactly customize the width, length, and eave height to satisfy your unique needs.

You can have a large factory that is 200 feet long, a tiny workshop that is 30 feet broad, or a certain height to fit certain equipment. You may also select from visually pleasing arched roofs, extremely efficient single-sloped roofs, or traditional straight-sloped roofs.

Additionally, a broad range of wall materials are available, from affordable and long-lasting corrugated metal panels to eye-catching sandwich panels, as well as combinations with brick or glass curtain walls, guaranteeing that the structure is both functional and consistent with your company’s image.

Understanding the Cost Analysis: What to Expect

Typical Building Dimensions and Cost Estimation Examples

The cost of industrial metal buildings kits varies significantly based on size, configuration, and geographic location, but understanding the general range aids in budget planning.

For example, within 30m span building, if you use basic type single steel plate as wall and roof material, without mezzanine and crane inside, the estimate price is around $50 per square meter. If you need insulation material on the wall and roof, the estimate price can go up to $70 to $100 per square meter depending on the material option. If your project need to consider the mezzanine and crane use, or harsh local environment such as high-wind resistance, the cost might be higher.

Analysis of Core Factors Affecting Industrial Metal Buildings Costs

The final cost is influenced by multiple factors.

- First, the dimensions and complexity of the building itself—such as larger spans, greater heights, and intricate layouts (e.g., multi-span or mezzanine designs)—naturally increase material and design costs.

- Second, material selection plays a role, as the market price of steel, the thickness and type of wall and roof panels (e.g., standard panels vs. insulated sandwich panels), and the specifications and quantity of doors and windows directly impact the total price.

- Third, site and foundation conditions matter, as challenging terrain or soft ground may require more expensive foundation engineering. Additionally, local building codes, wind and snow load standards, and other regional requirements can lead to variations in structural design and cost.

- Finally, the configuration of additional systems—such as interior finishes, insulation, ventilation, electrical work, and fire safety—significantly contributes to cost fluctuations.

Step-by-Step: The Industrial Metal Buildings Process

A comprehensive service process from concept to completion

A typical industrial metal building project follows a clear and efficient process.

The first step involves demand communication and on-site evaluation. Please share your detail requirements such as usage, size, design reference, budget with us.

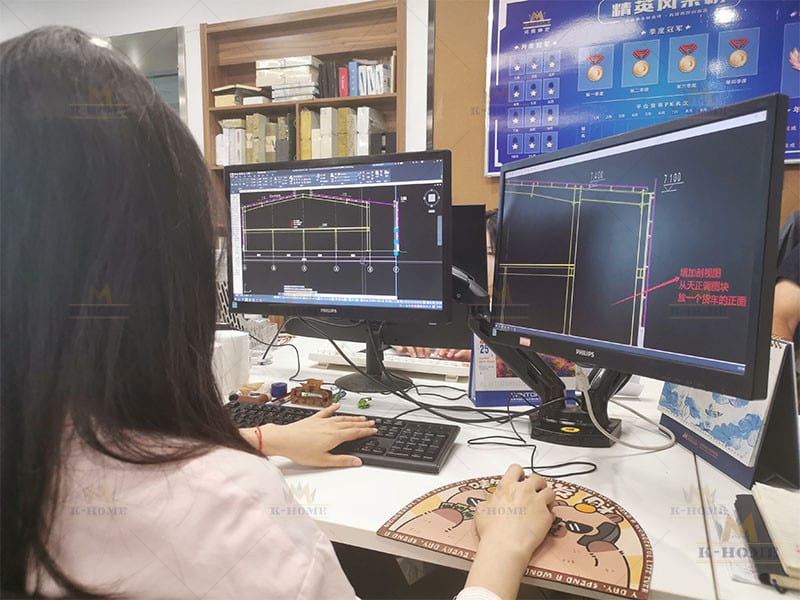

Then our engineer will make a preliminary drawing for your check. After you confirm on the drawing, we will make the budget for your approval.

The third step is factory prefabrication, where all steel components are precisely cut, drilled, welded, and treated for corrosion resistance according to the drawings, ensuring quality control.

On site construction and final delivery

The fourth step is on-site foundation construction, which is a crucial step to be completed by your construction team or a professional civil engineering team recommended by the supplier. This includes earthwork excavation, steel reinforcement binding, and concrete pouring, forming the “foundation” of the building.

The fifth step is the assembly of the main structure. After the prefabricated steel components arrive at the site, an experienced installation team will quickly assemble the columns, beams, purlins, etc. like building blocks. The progress of this stage is very fast.

The sixth step is the installation of the enclosure system, including roof panels, wall panels, doors and windows, as well as necessary sealing and waterproofing treatments.

Finally, there is the finishing and acceptance process, which involves completing the interior decoration, equipment installation, and overall debugging.

We will collaborate with you to conduct the final inspection to ensure that the building fully meets the specifications and expectations, and then deliver it for use.

Understanding the parameters of industrial metal buildings

| Component Structure | Material | Technical Parameters |

|---|---|---|

| Main Steel Structure | GJ / Q355B Steel | H-beam, Customized height according to building requirements |

| Secondary Steel Structure | Q235B; Paint or Hot Dip Gavalnized | H-beam, Spans range from 10 to 50 meters, depending on design |

| Roof System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to design |

| Wall System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to wall area |

| Window & Door | Color steel sliding door / electric rolling door Sliding Window | Door and window sizes are customized according to design |

| Fireproof Layer | Fire retardant coatings | Coating thickness (1-3mm) depends on the fire rating requirements |

| Drainage System | Color Steel &PVC | Downspout: Φ110 PVC Pipe Water Gutter: Color Steel 250x160x0.6mm |

| Installation Bolt | Q235B Anchor Bolt | M30x1200 / M24x900 |

| Installation Bolt | High-Strength Bolt | 10.9M20*75 |

| Installation Bolt | Common Bolt | 4.8M20x55 / 4.8M12x35 |

customized metal industrial buildings according to your application

K-HOME’s metal industrial buildings have been successfully implemented in numerous countries and regions worldwide, including African markets such as Mozambique, Guyana, Tanzania, Kenya, and Ghana; the Americas such as the Bahamas and Mexico; and Asian countries such as the Philippines and Malaysia. We are familiar with diverse climate conditions and approval systems, enabling us to provide you with steel structure solutions that combine safety, durability, and economy.

Contact our customer service team today, and we will dedicate ourselves to creating a customized metal structure building perfectly suited to your needs.

If you provide the following information, we will provide you with a more accurate product quote.

How to Select the Right Supplier?

Key Criteria for Identifying High-quality Industrial Metal Buildings Suppliers

Choosing the right supplier is the cornerstone of project success. Firstly, the industry experience and professional qualifications of the supplier should be examined. A company with years of experience, rich successful cases, and professional engineering design and construction qualifications is more trustworthy. Secondly, evaluate the quality of its products and services, understand the quality grade and coating standards of the steel used, and review the engineering capabilities and after-sales service system of its design team. Conducting on-site inspections of completed projects and communicating with past clients is an effective way to understand their actual construction level and service reputation.

Emphasize comprehensive service and transparent communication

Excellent suppliers should be able to provide one-stop services from consulting, design, quotation, to production and installation guidance. Industrial metal building company should not simply be material vendors, but partners in solutions. In the communication process, transparency is essential. To prevent future unforeseen costs, make sure the estimate is precise and succinct and includes a list of all included and excluded products. Suppliers should be able to assist you in optimizing the design to strike a balance between cost and usefulness while also providing a clear explanation of the building code requirements. Ultimately, choose a supplier with smooth communication, timely response, and a sense of peace of mind and support throughout the entire project process.

why K-HOME industrial metal buildings?

As a professional industrial metal building contractors, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.