Single-span vs Multi-span: A Complete Guide

In modern architecture, steel structures are increasingly widely used due to their excellent properties—high strength, light weight, good earthquake resistance, short construction period and strong design flexibility—and have become the preferred structural form for many large factories, warehouses and other buildings.

Among the various types of steel structure buildings, single-span and multi-span steel structures are two very common forms, thanks to their distinct characteristics and application scenarios. In practical projects, choosing between single-span and multi-span forms is a key concern for many clients. This choice not only directly affects the building structure, but also impacts the crane system and long-term operating costs.

What is a “span”?

In steel structure buildings, a “span” refers to the distance between the centers of load-bearing structures (such as columns) at both ends of a steel structural component, usually measured in meters. Span is a core indicator for measuring the spatial distribution range of steel structures. It determines the load-bearing performance and structural stability of components. For example, 7 spans correspond to 8 load-bearing structures, and 5 spans correspond to 6 load-bearing structures.

In practical applications, spans are divided into two categories: ordinary spans and large spans. The common range of ordinary spans is 6-30 meters, which is suitable for ordinary industrial plants. Spans exceeding 30 meters are classified as large-span structures, which are commonly used in special projects or large public facilities.

What are Single-span and Multi-span?

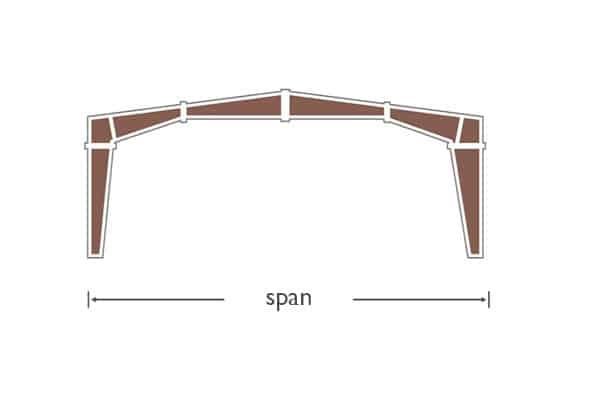

Single-span structure: A simple spatial framework

A single-span steel building is a simple and efficient type of steel structure. Its basic structure is relatively straightforward, mainly consisting of two columns and one beam. These two columns bear the vertical loads from the upper beam and the entire structure. The beam spans between the two columns, supporting various loads from the roof and transferring them to the columns.

Single-span frame can provide an open, column-free space with no internal column blocking it. This spacious layout offers great flexibility for the building’s functional use. In some church buildings, single-span rigid frames can create tall, sacred internal spaces, allowing worshippers to engage in religious activities in a roomy environment and feel a solemn atmosphere. In office building designs, such column-free spaces can be flexibly divided according to different office needs, facilitating the setup of open work areas, meeting rooms, etc., to meet the requirements of modern offices for spatial flexibility and openness.

Additionally, the construction of single-span is relatively simple. With fewer components, the installation process is relatively fast, which can effectively shorten the construction period and reduce construction costs. This makes them widely used in projects requiring rapid construction, such as temporary buildings and quickly-erected commercial facilities.

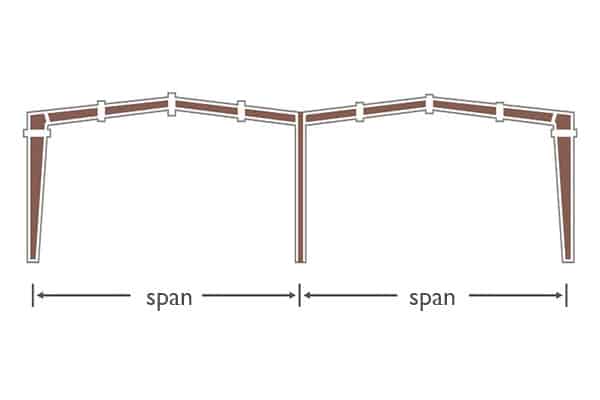

Multi-span structure: Combined spatial expansion

A multi-span steel building is formed by connecting and combining multiple single-span rigid frames, jointly expanding into a broader building space. Its structural feature lies in connecting beams of multiple spans through internal supporting columns, forming a continuous structural system. These supporting columns not only support the beams but also enhance the stability and load-bearing capacity of the entire structure, enabling multi-span rigid frames to meet the needs of larger-scale buildings.

The internal supporting columns of multi-span rigid frames increase structural strength, allowing them to bear greater loads. In some large industrial buildings, heavy mechanical equipment often needs to be placed, which generates significant vertical and vibration loads. Relying on its robust structural system, the multi-span rigid frame can effectively transfer these loads to the foundation, ensuring the safe use of the factory. At the same time, by properly arranging supporting columns, multi-span rigid frames can expand the effective usable area of the building and improve space utilization. In the design of large warehouses, multi-span rigid frames can be flexibly divided into different functional areas (such as storage areas, sorting areas, and passages) according to the needs of goods storage and transportation, realizing efficient space use.

Furthermore, multi-span rigid frames also have certain advantages in architectural modeling. Through the design of different span combinations and roof forms, they can create a variety of architectural appearances to meet the requirements of different architectural styles.

Differences and Connections Between Single-span and Multi-span Structures

Single-span and multi-span have obvious differences in several aspects. In terms of structural form, a single-span has a simple structure with only one span and no internal supporting columns. A multi-span, however, consists of multiple spans with internal supporting columns, making its structure relatively complex. Regarding the support system, single-span mainly rely on columns at both ends to support the beams and roof loads, resulting in a relatively simple support system. For multi-span, in addition to the columns at both ends, the intermediate supporting columns also play an important supporting role, forming a more complex and stable support system.

Internal space layout is another major difference between the two. Since single-span have no internal columns, their internal space is open and continuous, making them suitable for buildings that require large spaces and high flexibility in space division. Although multi-span have internal supporting columns, through reasonable column grid arrangement and space planning, they can form multiple relatively independent yet interconnected spaces. This makes them suitable for buildings that need to divide different functional areas, such as large factories and warehouses.

However, single-span and multi-span also share many connections. In terms of material selection, both use steel as the main structural material. Steel has advantages such as high strength, light weight, and good plasticity and toughness, which can meet the requirements of rigid frame structures for load-bearing capacity and deformation capacity. In terms of design specifications, both need to comply with the basic principles and relevant standards of steel structure design, such as Code for Design of Steel Structures (GB 50017-2017). These specifications and standards clearly stipulate the design, calculation, and structural requirements of the structure, ensuring the safety and reliability of both structural forms.

In addition, they have similarities in construction method. Components are first processed and manufactured in the factory, then transported to the construction site for assembly. This method not only improves construction efficiency but also ensures the processing accuracy and quality of the components. In terms of maintenance, both require regular inspection and maintenance to prevent steel from rusting and corroding, thus ensuring the service life of the structure.

How to Choose Single-span or Multi-span?

Functional Requirements

When a building requires an open, unobstructed large space, single-span steel structures become the first choice. Stadiums are typical application scenarios for single-span steel structures. Large sports events need an open space that can accommodate a large number of spectators and athletes, and single-span steel structures can easily meet this demand. For example, a large stadium adopts a single-span steel structure design, with an open internal space and spectator seats surrounding the competition field. Whether hosting ball games such as basketball and football, or events like gymnastics and track and field, it can provide a good experience for both athletes and spectators.

When a building needs to be divided into multiple areas to meet different functional needs, multi-span steel structures demonstrate their advantages. Comprehensive factories usually include multiple functional zones such as production areas, storage areas, and office areas. Multi-span steel structures can separate these functional zones by arranging internal supporting columns properly, while maintaining connectivity between zones to ensure smooth production processes.

Site Condition Constraints

Site conditions such as site shape, area, and surrounding environment all affect the suitability of the two structure types.

When the site shape is irregular or the area is narrow, single-span steel structures can be flexibly designed according to the actual site shape. Leveraging their simple structure, they can be built in limited space to meet functional requirements.

If the site is wide and regular, multi-span steel structures can better exert their advantage of high space utilization. In large industrial parks, sites are usually large and regularly shaped. Multi-span steel structures can make full use of the site space through reasonable column grid arrangement to build large-scale factories or warehouses.

The surrounding environment also influences the selection of steel structure types. If there are tall buildings or other obstacles around the site, they may adversely affect the lighting and ventilation of single-span steel structures. In such cases, multi-span steel structures can better solve lighting and ventilation issues by properly arranging internal supporting columns and lighting/ventilation facilities.

Cost-benefit Trade-off

Cost-benefit plays a key role in choosing between single-span and multi-span steel structures. Every link—from material costs and construction costs to maintenance costs—requires detailed analysis and trade-off to maximize the project’s economic benefits.

Material Costs

In terms of material costs, single-span steel structures usually require higher steel specifications and strength to bear larger span loads, which may increase material costs. Especially for large spans, single-span steel structures need to use steel beams with larger cross-sections and stronger columns to ensure structural stability. In contrast, multi-span steel structures share loads through internal supporting columns, so the load-bearing requirements for individual components are relatively lower. They can use steel of smaller specifications, reducing material costs to a certain extent. In a multi-span steel structure factory, each span is relatively small, and the loads on columns and beams are correspondingly reduced. Therefore, more economical steel specifications can be selected, lowering the total material procurement cost.

Construction Costs

Construction costs are also an important factor affecting the selection. The construction of single-span steel structures is relatively simple, with fewer components and faster installation. This can effectively shorten the construction period and reduce labor and machinery costs during construction. In projects requiring rapid construction—such as temporary buildings or emergency disaster relief facilities—the construction advantages of single-span steel structures are particularly prominent.

However, multi-span steel structures have relatively complex structures. Their construction requires more measurement, positioning, and connection work, leading to higher construction difficulty and potentially longer construction periods, which increases construction costs. In the construction of a large multi-span steel structure warehouse, it is necessary to accurately install steel beams and columns of multiple spans and ensure firm and reliable connections between them. This requires more construction time and professional technicians, resulting in higher construction costs.

Maintenance Costs

Maintenance costs also need to be considered. Single-span steel structures have simple structures, making maintenance work relatively easy. The workload of inspection and repair is small, and maintenance costs are relatively low. In contrast, multi-span steel structures have more internal supporting columns and complex structures, making maintenance work relatively cumbersome. They require more human and material resources, so maintenance costs may be higher.

In conclusion, please contact KHOME at the initial stage of your project design. We will recommend a suitable solution based on your actual usage needs (such as production requirements, equipment weight, and space utilization rate) and arrange for our professional structural engineers to conduct detailed calculations and verifications.

Choice for Large-span Warehouses: Single-span or Multi-span?

Characteristics and Requirements of Large-span Warehouses

A large-span warehouse generally refers to a warehouse building with a span of 30 meters or more. Its most notable feature is its vast internal space, which enables large-scale cargo storage and efficient handling.

In terms of cargo storage, large-span warehouses need to meet the stacking needs of different types of goods. Bulky items such as large mechanical equipment and construction materials require open space for stacking to facilitate storage and retrieval. For small items that need classified storage, warehouses also need to provide flexible space division to set up different storage areas.

Cargo handling is another key activity in large-span warehouses. To improve handling efficiency, large handling equipment such as forklifts and stackers are usually used inside. This equipment requires sufficient operating space to move, turn, load, and unload goods freely. At the same time, warehouses need to design reasonable passages to ensure smooth cargo handling and avoid traffic jams or cargo collisions.

Advantages and Limitations of Single-span Structures in Large-span Warehouses

In large-span warehouses, the biggest advantage of single-span steel structures lies in their column-free open space. This allows large-scale centralized stacking of goods and improves warehouse space utilization. For large handling equipment, the column-free space of single-span warehouses provides a broad operating area, allowing more efficient cargo handling. Forklifts can move freely inside the warehouse to quickly transport goods to designated locations, significantly improving handling efficiency.

However, single-span steel structures also have limitations in large-span warehouse applications. When the span is too large, the single-span structure has extremely high requirements for materials and structural design. To bear larger span loads, high-strength, large-specification steel is required. This not only increases material costs but also raises higher demands for steel supply and processing.

Application Considerations of Multi-span Structures in Large-span Warehouses

In large-span warehouse applications, multi-span steel structures can effectively distribute loads by arranging internal supporting columns properly. This reduces the load-bearing pressure on individual components, allowing the use of smaller-specification steel and lowering material costs.

Multi-span structures also enhance the flexibility of warehouse space. Through the combination of different spans and the layout of column grids, the warehouse can be divided into different functional areas such as storage areas, sorting areas, and passages, meeting the needs of storing and handling different types of goods.

Nevertheless, multi-span steel structures have some shortcomings in large-span warehouses. The presence of internal supporting columns may affect the smoothness of cargo handling. When using large handling equipment, special care must be taken to avoid collisions between the equipment and columns, which may reduce handling efficiency and increase operational difficulty.

In addition, the design and construction of multi-span steel structures are relatively complex. During the design phase, detailed mechanical analysis and calculations are required to ensure structural safety and rationality. During construction, columns and beams need to be installed with high precision to guarantee structural quality and accuracy. This increases the cost and time of design and construction.

About K-HOME

——Pre Engineered Building Manufacturers China

Henan K-home Steel Structure Co., Ltd is located in Xinxiang, Henan Province. Established in the year 2007, registered capital of RMB 20 million, covering an area of 100,000.00 square meters with 260 employees. We are engaged in prefabricated building design, project budget, fabrication, installation of steel structure and sandwich panels with second-grade general contracting qualification.

Custom size

We offer customized prefabricated steel structures in any size, perfectly matching your multiple requirements.

free design

We provide free professional CAD design. You don’t need to worry about unprofessional design affecting building safety.

Manufacturing

We select high-quality steel materials and use advanced processing techniques to ensure the creation of durable and robust steel structure buildings.

installation

our engineers will customize a 3D installation guide for you. You don’t need to worry about installation problems.

related blog

why K-HOME Steel building?

As a professional PEB manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.