Prefab warehouse mezzanine is also known as work platform, steel structure platform or steel platform. The platform structure is usually composed of planks, primary and secondary beams, columns, inter-column supports, as well as ladders and railings.

The prefab warehouse mezzanine is use form of building a steel structure composite floor in a building floor with too high floors so that one floor becomes two floors, such as residential buildings, office buildings, factories, venues and other buildings.

Modern steel structure platforms have various structures and functions. The biggest feature of its structure is the fully assembled structure, which is flexible in design. It can design and manufacture steel structure platforms that meet site requirements, functional requirements and logistics requirements according to different site conditions.

Learn More About Residential Metal Garage Buildings

The type of Prefab Steel structure warehouse mezzanine

Steel structure cement pressure plate combination

Secondary beam purlin (spacing about 600mm) + cement fiberboard (or OSB Osong board) + about 40mm thick fine stone light concrete (optional) + decorative surface layer;

This structural scheme has the advantages of low cost, lightweight and short construction period;

Steel Structure Lightweight Board Composite Floor

Method: about 100mm thick ALC aerated concrete slab + about 30mm rear mortar leveling layer decorative surface layer;

This structural combination scheme has the advantages of safety and environmental protection, lightweight, high strength, long-lasting non-deformation, fast construction, short construction period, good thermal insulation and sound insulation effect, and can also be installed at the same height as the upper flange of the steel beam, maximizing the use of effective space. Suitable for office buildings, residences, light workshops, etc.

Steel Structure Steel Floor Deck

Practice: the spacing between the secondary beam purlins (or stiffening ribs) is less than 600mm + floor deck (or grid plate) + about 40mm thick fine stone concrete (optional) + decorative surface layer (optional);

This structural combination scheme is suitable for industrial workshops, workshops, equipment rooms and other buildings, with good load-bearing effect, fast construction, etc.

For houses with very high stories, adding a steel structure interlayer (interlayer) indoors is the best way to increase the usable area of the house. The modern steel structure interlayer has various forms and functions. The biggest feature of its structure is its fully assembled structure, flexible design, can design and manufacture steel structure interlayers that meet the requirements and functional requirements according to different site conditions.

Prefab Metal Warehouse: Design, Type, Cost

The Detail Of Floor Bearing Deck

Preparation Before Installation

Familiarize yourself with the drawings carefully, understand the layout distribution, size control and positional relationship of the profiled floor deck and its position on the steel beam; before installation, focus on checking the flatness and perfection of the steel beam, and carefully clean the surface of the steel beam Sundries and dust; check whether there is anti-corrosion process on the surface of the steel beam, if there is, the anti-corrosion surface must be polished off; and according to the layout of the drawings and the building axis, measure and lay out the line on the surface of the steel beam, and make a mark.

Installation Process Of Profiled Floor Slab

Hoisting and laying: When shipping, the steel structure manufacturer should pack the installation unit as a unit and transport it to the construction site, and stack it neatly at the destination according to the paving sequence;

Before hoisting, the staff must confirm the plate type, size, quantity, location and accessories according to the design and construction drawings. After the installation sequence and progress of the main structure are correct, they will be hoisted to each construction location and stacked neatly. Please note: The stacking should be scattered, and slowly lowered on the beam, do not hoist roughly. Such vulnerable components are also likely to cause safety accidents;

In order to ensure that the profiled floor deck does not deform during hoisting and transportation, soft slings should be used, or rubber should be added where the steel wire rope and the board are in contact, or dunnage should be used under the steel plate, but it must be firmly tied.

During the stacking process, keep the width of the supports at both ends consistent to avoid falling accidents caused by dumping;

Rough installation should be carried out first when laying to ensure that the corrugations are straight so that the steel bars can pass smoothly in the “wave valley”. After the hoisting is in place, start from the laying line where the steel beam has been ejected, and adjust the slab seam appropriately after extending the laying direction to the control line.

When laying irregular panels, according to the layout of the steel beams on-site, the centerline of the steel beams should be used to layout the line, and the floor deck should be assembled and demonstrated on the ground platform, and then the control line should be released, and then according to its width. Typesetting and cutting.

It should be noted that construction is prohibited when the wind speed is greater than or equal to 6m/s. If it is disassembled, it should be re-bundled. Otherwise, the profiled floor slab may be blown up by the strong wind, causing damage and safety accidents.

Fixed

The lap length of the profiled floor deck shall be lapped according to the design requirements. The lap between one side and the end and the supporting steel beam shall not be less than 50mm. The steel plates are separated due to load-bearing and should be fixed or welded with embedded clips at the side lap joints, with a maximum spacing of 900mm.

Please note: Any unsecured components may be blown up or slipped by high winds and cause an accident.

The advantages of floor deck compared with the ordinary reinforced concrete floor:

- In the construction stage, the floor deck can be used as the continuous lateral support of the steel beam, which improves the overall stable bearing capacity of the steel beam; in the use stage, the overall stability of the steel beam and the local stability of the upper flange are improved.

- According to the different section shapes of the profiled steel plates, the floor concrete consumption can be reduced by up to 30%. The reduced dead weight of the floor slab can correspondingly reduce the dimensions of beams, columns and foundations, improve the overall performance of the structure and reduce the engineering cost.

- When the floor deck is installed, it can be used as a construction platform. At the same time, because there is no need to use temporary support, it does not affect the work of the next floor construction plane.

- The floor deck can be used as the bottom reinforcement of the floor slab, which reduces the workload of installing the reinforcement.

- The rib of the profiled steel plate can be placed with water and electricity pipelines, so that the structural layer and the pipeline are integrated into one body, which indirectly increases the height of the floor or reduces the height of the building, bringing flexibility to the building design.

- Floor deck can be used as permanent formwork for cast-in-place concrete. This saves the process of installing and removing formwork during construction, thereby saving time and labor.

Further Reading: Steel Building Plans and Specifications

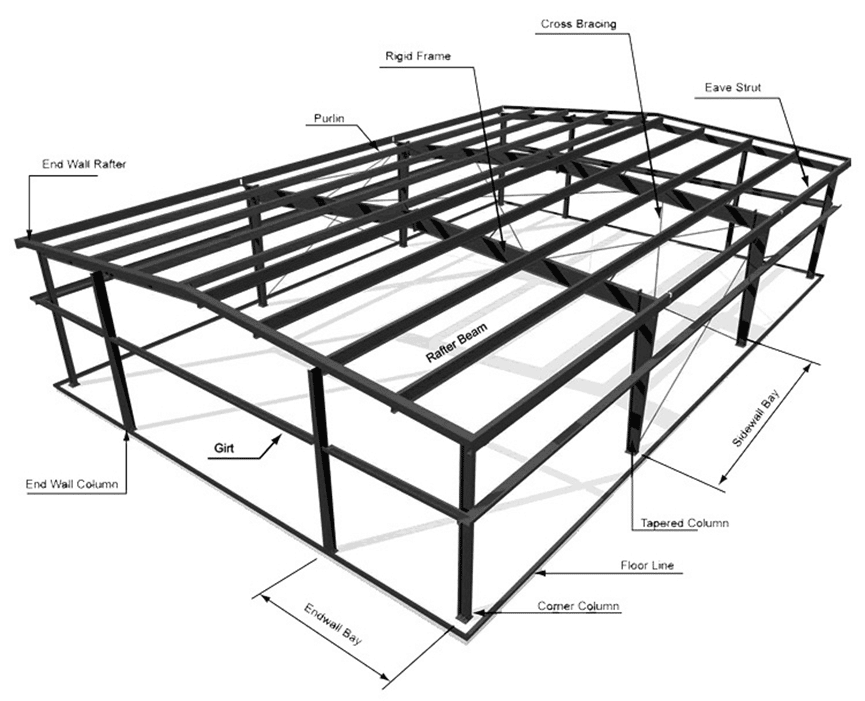

The PEB Steel Building

The Other Additional Attachments

Building FAQs

- How to Design Steel Building Components & Parts

- How Much Does a Steel Building Cost

- Pre-Construction Services

- What is a Steel Portal Framed Construction

- How to Read Structural Steel Drawings

Blogs Selected for You

- The Main Factors Affecting The Cost of Steel Structure Warehouse

- How Steel Buildings Help Reduce Environmental Impact

- How to Read Structural Steel Drawings

- Are Metal Buildings Cheaper Than Wood Buildings?

- Benefits of Metal Buildings For Agricultural Use

- Choosing the Right Location For Your Metal Building

- Making a Prefab Steel Church

- Passive Housing & Metal –Made for Each Other

- Uses for Metal Structures You May Not Have Known

- Why Do You Need a Prefabricated Home

- What Do You Need To Know Before Designing a Steel Structure Workshop?

- Why Should You Choose a Steel Frame Home Over a Wooden Frame Home

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.