Modern Warehouse Structures: Prefabricated, Steel & PEB Solutions

prefabricated warehouse / steel warehouse structure / temporary warehouse structure / warehouse peb structure / warehouse metal structure

Warehouse structures are spaces specifically designed to store goods and products. These vital commercial assets come in a variety of forms, tailored to the diverse needs of various industries. Traditionally, they were constructed using materials such as concrete and brick. While these structures provide the necessary storage space and can handle large amounts of inventory, they often come with longer construction times and increased costs.

Today, steel warehouse structures have become the preferred solution for building modern and efficient storage facilities. Pre-engineered building (PEB) methods have revolutionized construction methods, offering a faster, more efficient, and more adaptable approach to creating vital storage space.

What is a prefabricated warehouse structure?

Prefabricated warehouse structures represent a shift in modern industrial construction methods. Unlike traditional on-site construction, warehouse structures are designed and manufactured in a controlled factory environment. Core components (primary steel frames), secondary elements (wall and roof panels), and critical connecting parts are manufactured to precise specifications and then transported to the project site for rapid assembly.

This prefabricated warehouse structure stands in stark contrast to traditional concrete or brick warehouses. Traditional warehouses are often plagued by weather delays, unpredictable construction schedules, and inconsistent on-site construction quality. Steel warehouse structures replace these uncertainties with manufacturing efficiency and assembly-line precision. Because each component is produced under strict quality control procedures, the construction process is not only faster but also consistently high quality.

The advantages of choosing this modern warehouse structure are clear:

- Speed of Construction: Since site preparation and factory fabrication can occur simultaneously, project timelines are drastically reduced. A prefabricated warehouse structure can be weather-tight and operational in a matter of weeks, not months, allowing you to start operations and generate ROI much faster.

- Cost-Effectiveness: The controlled manufacturing process minimizes material waste and reduces the need for extensive on-site labor. Steel structures also require minimal maintenance, significantly reducing ongoing costs.

- Durability: Factory-based production ensures that every component of a steel warehouse structure meets precise dimensional tolerances. This results in buildings with superior fit and finish, enhanced structural integrity, and long-term reliability.

- Steel’s strength, flexibility, and lightness make it an ideal backbone for any prefabricated warehouse structure. This synergy between prefabrication and steel makes the design and construction of warehouse PEB structures (prefabricated building) possible.

At K-HOME, we specialize in delivering these advantages. Our expertise lies in designing and manufacturing high-performance prefabricated warehouse structural solutions that are not only quick to deploy but also meet international standards for safety and durability.

Ready to Build?

Get a Free, No-Obligation Quote for Your Prefabricated Warehouse Project Today.

Choose the best warehouse structure type: PEB steel structure

Warehouses are core facilities for logistics and supply chain management. Warehouse structure types are widely. Traditional concrete or brick structures are among the most common. They provide basic storage space, but in modern industrial buildings, these structures struggle to meet the demands of fast and efficient storage.

Today, the leading warehouse structural solution is pre-engineered steel buildings (PEBs). PEBs represent a more advanced form of steel warehouse construction. Using integrated design software, they optimize, design, and manufacture the primary steel frame, secondary components, and enclosure systems as a single entity, optimizing material usage and maximizing construction efficiency, revolutionizing warehouse construction.

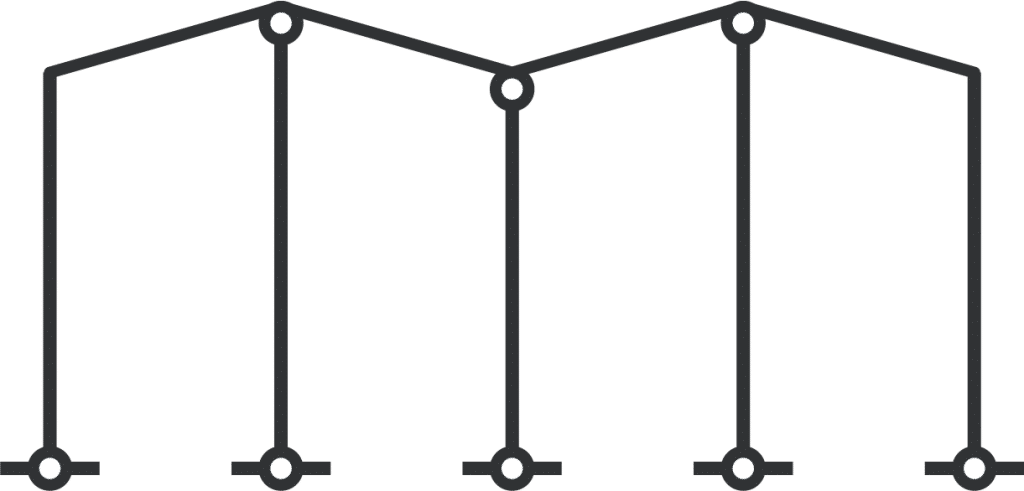

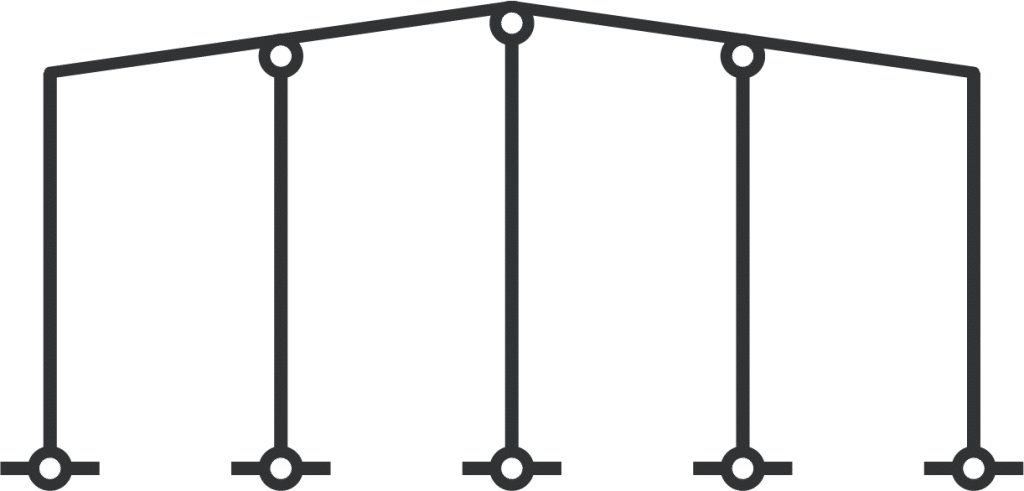

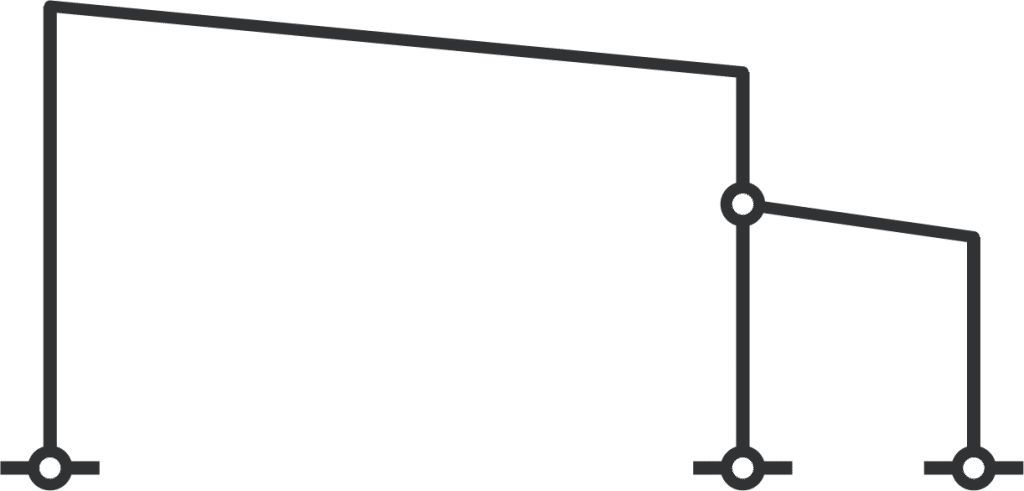

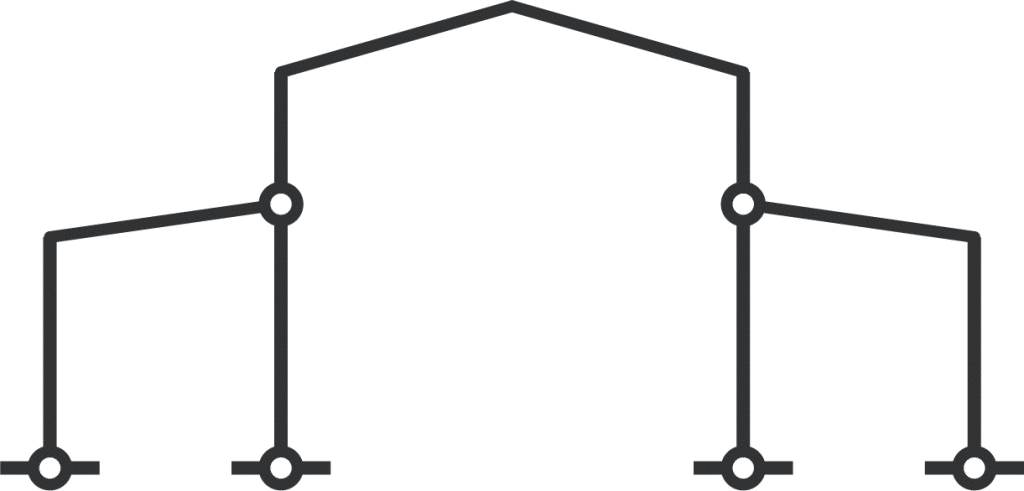

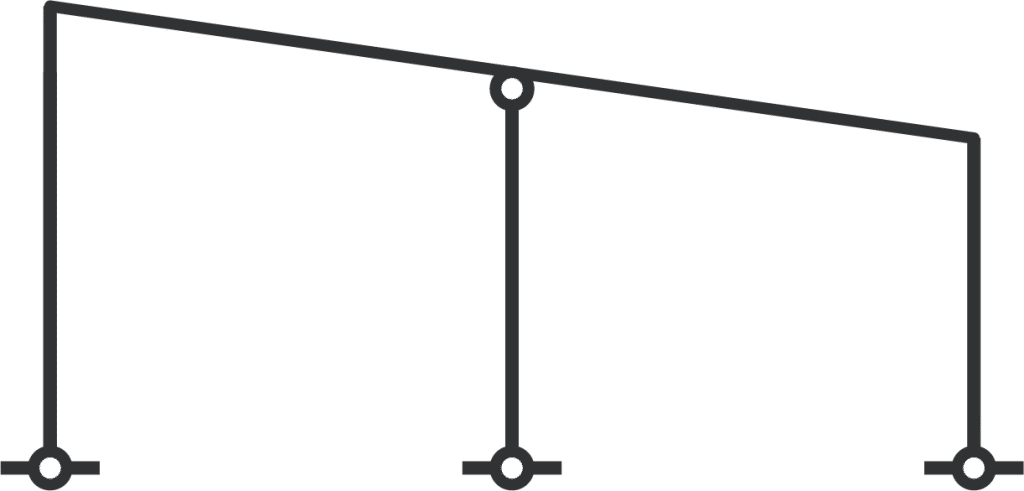

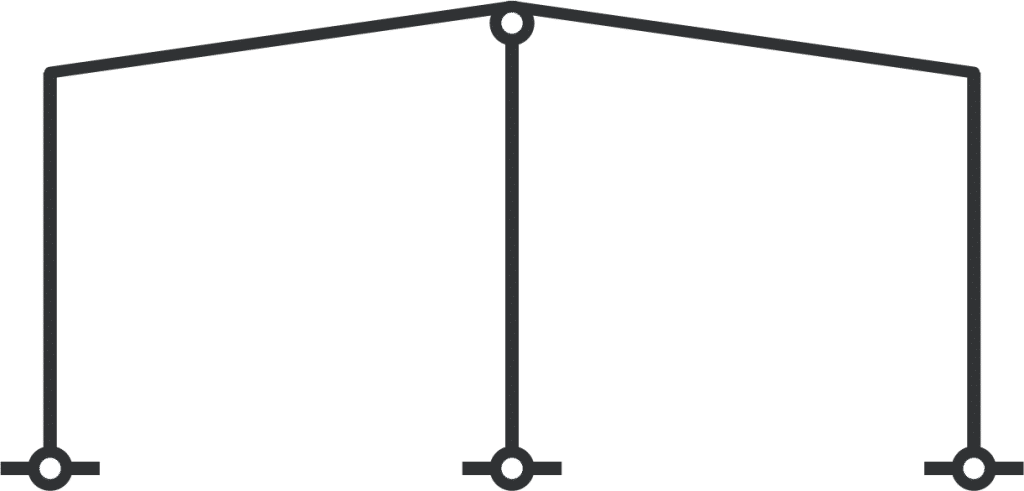

Among the many warehouse structural types, steel portal frames are widely recognized as one of the most ideal choices.

Single-span Overhanging Eaves Single-span Double-sloped Roofs Multi-span Multi Double-sloped Roofs Multi-span Double-sloped Roofs High-low Span Single-sloped Roofs High-low Span Double-sloped Roofs Double-span Single-sloped Roofs Double-span Double-sloped Roofs

This structure effectively resists lateral wind loads and longitudinal seismic forces, ensuring warehouse safety and stability in harsh environments.

Furthermore, this structure easily achieves large spans and column-free clearance, significantly improving space utilization and warehouse operational efficiency (e.g., facilitating forklift turns and racking layout). It can also be flexibly designed as a multi-span structure based on actual storage capacity and logistics flow requirements.

In addition, modern warehouse structures offer a wide range of enclosure systems. K-HOME’s solutions are not limited to standard lightweight color-coated steel panels; they can also incorporate hybrid designs of lightweight materials and brick walls, ensuring overall lightweight construction while meeting diverse functional requirements.

When constructing a warehouse structure, it’s crucial to partner with a reliable builder or manufacturer, K-HOME. Leveraging its expertise in PEB, K-HOME is committed to providing customized, high-performance steel warehouse solutions to clients worldwide. We help you secure storage space that adapts to future business growth with faster speeds and better investment. The following are some common warehouse structure applications:

Supply Chain Warehouse

Freight Warehouse

Steel Distribution Centers

warehouse steel structure building design

Scientific and rational structural design is key to ensuring that steel warehouse structures are safe, economical, and meet functional requirements. A complete and efficient warehouse steel structure building design process begins with a precise understanding of the project’s core parameters and continues through the meticulous calculation of every component. Two key elements must be clearly defined during the initial design phase:

- Building purpose and requirements: The warehouse’s specific function (such as storing general cargo, cold chain, or high-risk goods) directly determines its clear height, span, load requirements, and internal layout, forming the starting point for all design decisions.

- Environmental loads and geological conditions: The design must strictly adhere to the building’s natural environment, accurately calculating wind and snow loads, and determining seismic mitigation measures based on the designated earthquake severity rating. Furthermore, a geological survey report is crucial for a safe and economical design.

After determining these parameters, engineers will determine the optimal warehouse steel structure system. Using specialized software for structural calculations and simulation analysis, they will accurately determine the required steel volume, optimizing costs while ensuring absolute safety.

A complete steel warehouse structure consists primarily of the following systems:

- Main frame system: Typically employing a portal steel frame system, it serves as the backbone that carries all primary loads.

- Secondary structure system: This includes purlins, wall beams, and braces, transferring loads and enhancing overall structural stability.

- Enclosure system: Consisting of roof and wall panels, it forms the building envelope, meeting thermal insulation, daylighting, and aesthetic requirements.

- Foundation system: This reliably transfers superstructure loads to the foundation, and its design is closely tied to geological conditions.

The foundation, as the foundation of the factory building structure, bears all loads from the superstructure and safely transfers them to the substructure. Since steel structures are light in weight but sensitive to uneven settlement, foundation design must be carried out based on detailed geological survey data, fully considering foundation conditions to ensure that the foundation form matches the foundation bearing capacity and ensure the safety and durability of the overall structure.

The primary structure of the steel workshop building consists of steel columns, steel beams, and steel roof trusses. These primary components are reliably connected through welding or high-strength bolts, forming a strong and stable spatial structure.

The secondary structure, also known as the support system, primarily includes purlins, column braces, horizontal braces, and corner braces. These components work in conjunction with the primary structure to effectively transfer longitudinal and transverse loads, enhancing the building’s overall rigidity and lateral resistance, and ensuring structural safety under wind, earthquake, and other forces.

The exterior walls and roofing system form the building’s envelope and are generally constructed from lightweight, high-strength color-coated steel plates. In areas with high thermal insulation requirements, materials such as insulated sandwich panels can also be used to meet thermal performance requirements. This type of enclosure material not only offers excellent waterproof and fire resistance but also offers the advantages of easy and economical construction.

wall system wall system roof system roof system

K-HOME’s design team is proficient in the entire process, from conceptual planning to detailed design. We diligently integrate client needs with regulatory standards to deliver safe, cost-effective, and efficient steel warehouse design solutions.

why K-HOME Steel building?

As a professional PEB manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.