clear span buildings: The Ultimate Guide | Define, Advantage, Application

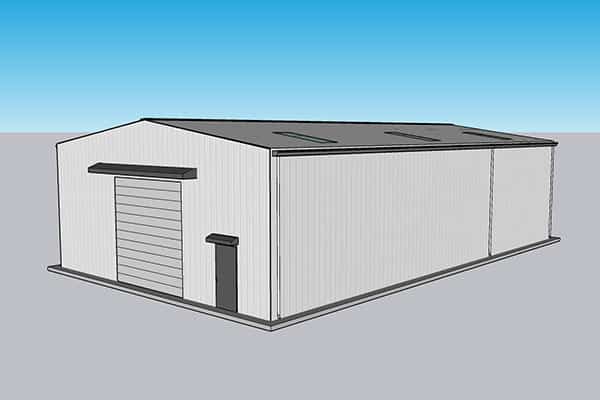

For projects like industrial plants, warehouses, and agricultural buildings, efficient and flexible interior space is often a top priority. In these cases, clear span buildings are a proven and reliable solution.

Clear span steel building systems use pre-engineered steel structures. The key feature is its design, which eliminates the need for internal support columns within a specific range (typically 20 to 30 meters). As a result, it creates a wide, unobstructed area for operations.

This open layout offers practical benefits. For instance, it allows for easier placement of large equipment and improves the flow of goods. Additionally, it provides valuable flexibility for future reconfigurations of the workspace.

This article provides a straightforward overview of clear-span buildings. It covers their core features, advantages, and suitable applications. It also addresses practical concerns, such as how to select the right span and what factors influence the cost. Our goal is to offer useful information to support your project planning.

What Are Clear Span Buildings?

A Clear Span Building is a large-span structure built without internal support columns. It is typically made from pre-engineered steel and assembled on-site.

This unique design creates a completely open interior space. As a result, there are no columns or obstacles, which maximizes the usable area.

Because of their wide, unobstructed layout, these buildings are ideal for many applications. For example, they are commonly used in warehouses, workshops, sports arenas, exhibition halls, and agricultural barns.

The steel structure buildings achieve these long spans through carefully designed steel beams and frames. This specific engineering ensures the structure remains both stable and secure.

Characteristics of Steel Clear Span Buildings

Steel clear-span buildings offer distinct advantages due to their structural design. They are made from high-strength steel, which ensures durability and strong resistance to harsh conditions. Additionally, their pre-engineered components streamline the construction process.

Key features include excellent load-bearing capacity, fire resistance, and seismic performance. These qualities allow the buildings to remain stable even in demanding environments.

Moreover, steel is recyclable, making these buildings an environmentally friendly option that supports green building trends.

Another important advantage is their high degree of customization. Owners can adapt the size, layout, and exterior to meet specific needs, making them suitable for various applications.

In summary, steel clear-span buildings successfully combine strength, adaptability, and cost-effectiveness, making them an ideal solution for many projects.

Advantages of Steel Structures

The primary advantage of clear-span steel buildings lies in the inherent strength of the steel frame. Steel is a high-strength material capable of supporting heavy loads and resisting extreme pressure. As a result, these structures remain safe and reliable even in harsh conditions, such as strong winds, earthquakes, or heavy snow.

Furthermore, steel offers natural fire resistance, which significantly reduces fire risk and provides extra protection for both equipment and personnel inside.

Another major benefit is construction speed. Since components are prefabricated off-site, on-site assembly is much faster. This efficiency reduces both labor costs and project timelines.

Additionally, these buildings are highly expandable. If more space is needed, new modules can be added easily without demolishing the existing structure.

Finally, steel’s durability leads to low maintenance requirements, offering higher cost-effectiveness over the long term.

In summary, these advantages make steel clear-span buildings a practical and widely used solution across industrial, commercial, and agricultural sectors, helping users achieve efficient space management.

Clear Span steel Building’s Span Range

The span width of clear span buildings typically ranges from 20 meters to over 100 meters. The final width depends on the design, materials, and project requirements.

Choosing the right span is essential. It ensures the building is both functional and cost-effective. Generally, a larger span provides more open interior space. However, it also increases both cost and structural complexity.

Therefore, the decision should be based on the building’s purpose, budget, and site conditions. For example, a small warehouse might only need a 20-30 meter span, while a large sports arena could require over 80 meters.

It’s also important to consider local climate factors, such as wind and snow loads. This ensures the structure remains safe and reliable.

Ultimately, with professional assessment and planning, you can select the most suitable span. This balances spatial needs with investment return.

Steel Building Span Selection Guide

The main objective of the construction must be understood before choosing the span of a Clear Span Building.

For instance, agricultural buildings often use spans of 20-40 meters. This provides ample growing space while keeping costs manageable. For industrial warehouses, spans typically range from 30-60 meters. This width supports efficient logistics and material handling.

Additionally, the choice of materials and engineering technology matters. Advanced steel designs can achieve wider spans, but they require higher engineering standards.

To meet the needs of business growth, users should also consider future expansion possibilities and choose an adjustable span design.

When selecting a span, we recommend consulting with professional engineers, as they can propose the optimal span solution through load calculations and environmental condition simulations.

In short, selecting the clear span of a building is a comprehensive process that requires balancing functionality, safety, and economy, and maximizing the building’s value through thorough decision-making.

the Frame styles of clear span metal buildings

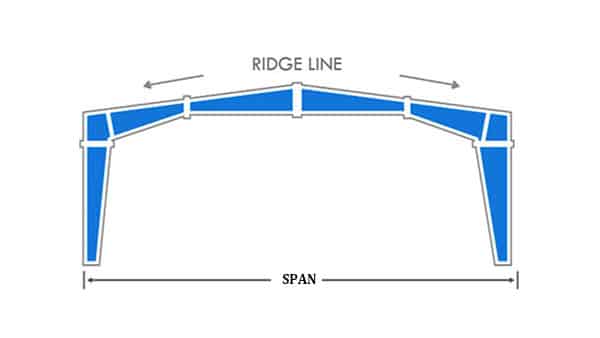

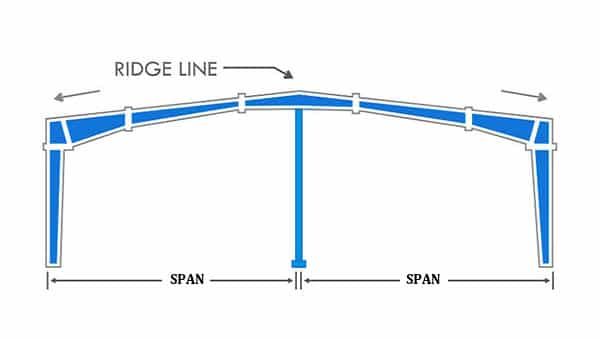

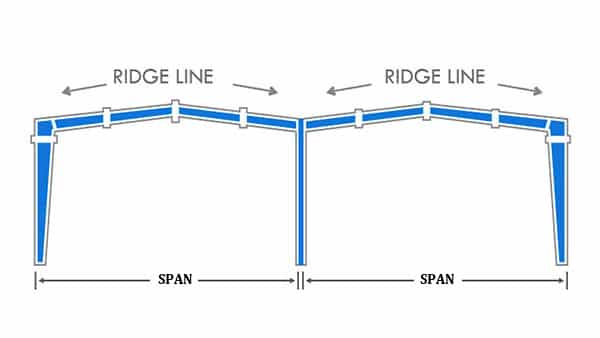

The framework styles of Clear Span Metal Buildings are diverse, each designed for different applications and environments.

Common types of frames include rigid frames, arch frames, and portal frames, each of which differs in structural strength, construction difficulty, and cost.

Rigid frames are known for their high stability and load-bearing capacity, making them suitable for large industrial buildings;

Arched frames provide a graceful curved appearance and are commonly used in sports or exhibition venues;

The portal frame is simple and economical, suitable for small-scale warehousing or agricultural use.

The choice of framework style for Clear Span Metal Buildings will affect the overall performance and aesthetics of the building, so users need to evaluate it based on specific needs. By understanding the characteristics of different frameworks, Clear Span Buildings can be better customized to achieve a perfect combination of functionality and form.

The price of clear-span steel buildings

Clear Span Buildings vary from $40 to $100 per square meter based on the size, design, materials, degree of customization, and local climate.

For example, if you only need a very simple structure with no crane and no mezzanine, and only single steel sheet for the wall and roof, then the typical cost might between $40 to $70 per square meter.

If the span is larger than 30m, and need insulation material on the roof and wall, and you need it to resist high wind speed, then the cost will be higher.

But don’t worry, our professional engineers will calculate the structure for you, to guarantee the high strength of the structure while keeping the cost effective for you. Therefore, when planning a project, please share more information about your project so we can understand your needs well.

Cost Analysis And Budget Recommendations

It is necessary to approach the pricing study of Clear Span Buildings from several angles.

First, the primary factor is material cost, and changes in the cost of high-strength steel will have an immediate impact on the budget as a whole.

Second, the expense of design: Although they might better suit particular demands, customized clear span buildings are typically more costly than regular designs.

Because Clear Span Buildings need a solid foundation to sustain large-span buildings, which might raise civil engineering expenditures, foundation engineering is also crucial.

Furthermore, the cost of on-site assembly is determined by the complexity and length of construction, and costs may increase in remote or difficult-to-reach locations.

To control the price of Clear Span Buildings, users can choose prefabricated components, reduce on-site workload, and negotiate bulk discounts with manufacturers. At the same time, considering energy efficiency characteristics such as insulation layers, although the initial investment is high, it can reduce long-term operating costs.

In summary, the price management of Clear Span Buildings requires a balance between quality and economy, achieving optimal cost-effectiveness through detailed planning and comparison.

foundation of steel structure building | Design

Designing a steel structure building foundation is a complex process that requires comprehensive consideration of multiple factors to ensure its safety and stability. The following are some key steps and key points for designing a steel structure factory building foundation:

Choosing a foundation type: When selecting a foundation type for a prefabricated steel building, factors such as geological conditions, soil properties and distribution, and groundwater conditions need to be considered. Generally speaking, if the geological conditions are good, an independent foundation can be used; if the geological conditions are poor, a pile foundation can be considered.

Foundation load analysis: The load characteristics of a steel structure factory building foundation are that the top surface bears relatively small vertical forces and relatively large horizontal forces and bending moments. Therefore, when designing the foundation, it is necessary to conduct a detailed analysis of these loads and determine the load distribution based on the structural characteristics, thereby verifying the foundation’s bearing capacity and stability.

Strictly follow the design steps: When designing a steel structure factory building foundation, it is necessary to follow a specific design procedure. This includes determining the location of the column base and the arrangement and layout of the piles, calculating the foundation height, determining the base area, and verifying the foundation’s punching shear strength.

Addressing Key Issues: Key issues may arise during the foundation design of a steel structure factory building, such as the pile base structure, reinforcement cover, and foundation anti-floating properties. These issues can significantly impact foundation stability and must be properly addressed.

The above are the main steps and key points in the design of a steel structure factory building foundation. It’s important to note that these steps and key points are not isolated; they are closely intertwined. During the actual design process, it’s necessary to comprehensively consider various factors and flexibly apply these steps and key points to ensure a safe and economical factory building foundation design.

Application Of Clear Span Pre-Engineered Buildings

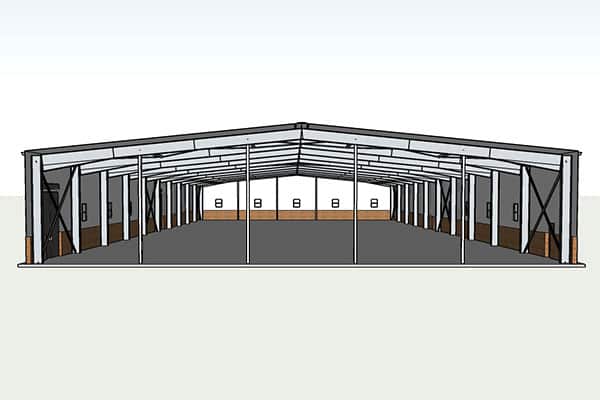

Precast buildings with clear spans have a wide range of applications, covering multiple sectors including industry, commerce, agriculture, and public utilities.

In the industrial sector, they are commonly used in industrial buildings and warehouses, providing open spaces for production and storage.

In the commercial sector, precast buildings with clear spans allow for flexible layouts and can be used as retail stores or exhibition centers in commercial spaces.

In agriculture, they are used for livestock sheds and greenhouses to maximize planting and breeding conditions.

The versatility of these buildings also extends to their use as hangars, sports stadiums, and emergency shelters.

Precast buildings with clear spans are ideal for a variety of projects due to their high customizability and rapid deployment. Real-world examples demonstrate how precast buildings with clear spans can help users improve efficiency and adaptability.

About K-HOME

——Pre Engineered steel Building Manufacturers China

Design

Every designer in our team has at least 10 years of experience. You don’t have to worry about the unprofessional design affecting the safety of the building.

Mark and Transportation

In order to make you clear and reduce the site work, we meticulously mark each part with labels, and all parts will be planned in advance to reduce the number of packings for you

Manufacturing

Our factory has 2 production workshops with large production capacity and short delivery time. Generally, the lead time is around 15 days.

Detailed Installation

If this is the first time for you to install the steel building, our engineer will customize a 3D installation guide for you. You don’t need to worry about the installation.

why K-HOME clear span Steel building?

As a professional clear span building manufacturer, K-HOME is committed to providing you with high-quality, economical steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.