In industrial buildings, manufacturing plants, and large-scale warehousing facilities, the steel structure crane beam serves as a key component of heavy-load handling systems. It directly dictates the operational safety and efficiency of equipment such as overhead cranes and gantry cranes, acting as a vital link between building structures and production operations. Whether you are an engineering designer, project construction manager, or facility maintenance technician, mastering the core fundamental knowledge of steel structure crane beams will help you make more informed decisions in project planning, selection, and procurement, or daily operation and maintenance.

What You Need to Know About Steel Structure Crane Beam?

It’s important to understand that the essence of the steel structure crane beam is more than just a “load-bearing beam”—it is a specialized load-bearing structural component designed to support hoisting equipment. Primarily fabricated from high-strength steel, it is installed on the top of factory columns or dedicated supports, providing a stable operating track and load-bearing fulcrum for cranes.

It is not an enhanced version of ordinary building beams: ordinary beams only bear static vertical loads, while the steel crane beam must simultaneously withstand the crane’s own weight, the static load of lifted heavy objects, as well as dynamic loads, lateral forces, and torques generated during equipment startup, braking, and steering. This requires it to meet more stringent standards for strength, stiffness, stability, and fatigue resistance.

Core Functions of Steel Structure Crane Beams: Differentiated from Ordinary Beams

Beyond its basic load-transmitting function, the steel structure crane beam offers two additional core capabilities:

- Ensuring precise operation tracks: It provides high-precision running paths for crane wheels, controlling track flatness and beam deflection. This not only enhances the accuracy of hoisting operations but also reduces the impact of equipment vibration on workpieces and building structures.

- Absorbing impacts and optimizing the working environment: Its structural design cushions the impact forces during operation, minimizing wear on crane wheels and tracks while reducing operational noise, creating a safer and more comfortable workshop environment.

These core functions are interrelated and complementary, directly influencing the overall performance and service life of the hoisting system.

Component Composition and Performance of Steel Structure Crane Beams

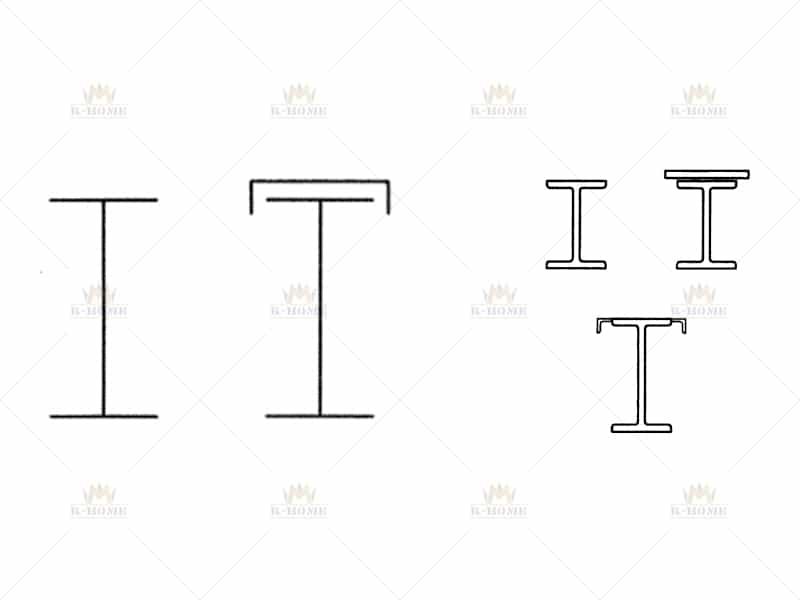

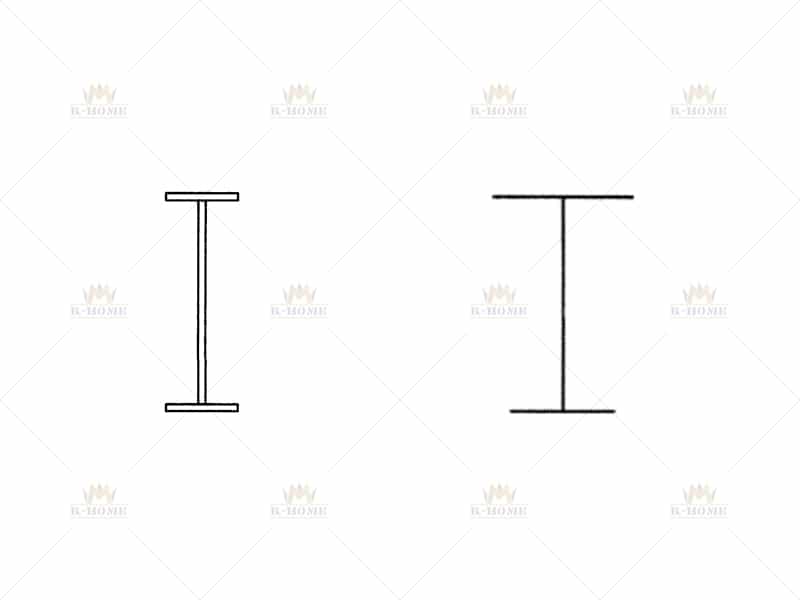

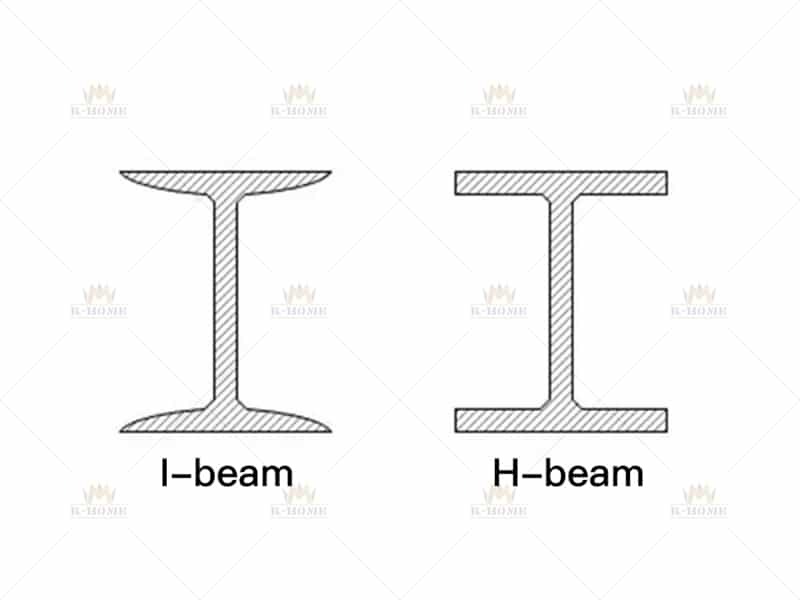

The components of a steel structure crane beam directly influence its performance. The cross-sectional shape of the main structure (such as an I-beam, H-beam, or box section) dictates its load-bearing capacity and stiffness; among these, the box section offers significantly superior torsional resistance compared to the I-beam, making it suitable for complex load-bearing scenarios. The quality of connecting components, including bolt strength and welding craftsmanship, directly affects structural stability; poor weld quality or loose bolts can easily lead to uneven load transmission and local stress concentration.

Lateral bracing and torsion-resistant devices in auxiliary components effectively prevent beam instability under heavy loads or lateral forces. At the same time, the precision of track fasteners directly impacts the smoothness of crane operation. Understanding the correlation between composition and performance is the core basis for evaluating the quality of a structure of crane beam.

Common Types and Selection Criteria for Crane Beams in Steel Structures

Most popular science content merely lists crane beam types, overlooking the core logic of precision selection based on specific needs. By integrating key factors such as load capacity, span, and environment, this section breaks down type differences to help you avoid the pitfalls of blind selection.

Selection by Structural Form: Correctly Matching Load Capacity and Span

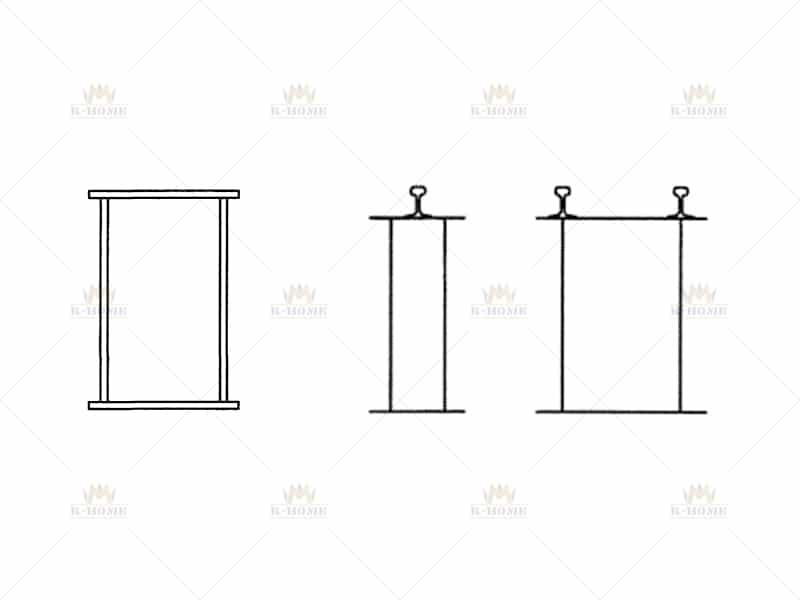

- Single-Girder Steel Crane Beams: Featuring a simple structure, light weight, and low cost, single-girder models have limited load-bearing capacity and stiffness. They are best suited for scenarios with load capacity ≤ 20 tons, span ≤ 20 meters, and low operation frequency—such as small warehouses, light production lines, and intermittent hoisting tasks.

- Double-Girder Steel Crane Beams: Composed of two parallel main girders, double-girder beams offer enhanced stiffness and higher load-bearing capacity. They are ideal for applications with load capacity ≥ 20 tons, span 20-30 meters, or high operation frequency—including heavy machinery plants, steel mills, and continuous production operations.

- Truss-Type Crane Beams: Lightweight and highly adaptable to large spans, truss-type beams excel in large-span but medium-load scenarios. A typical use case is light warehousing with spans ≥ 30 meters, where their weight advantage and span flexibility provide practical value.

- Box-Section Crane Beams: With excellent torsion resistance and stiffness, box-section beams are designed for heavy-load and complex force-bearing scenarios—such as heavy equipment hoisting in ports and power plants. Note that they require higher manufacturing costs and stricter installation standards.

Core Selection Principle: Avoid over-configuring beyond budget constraints or opting for underperforming low-cost solutions. The key is to balance performance and cost based on three critical factors: load capacity, span, and operation frequency.

Steel Crane Beams: Material Grade Selection for Environmental & Strength Alignment

Q235 steel and Q345 steel are the mainstream materials for steel crane beams, and it does not mean the latter is inherently superior to the former.

Q235 steel offers good ductility, excellent weldability, and low cost, making it suitable for ordinary industrial plants with indoor dry environments, medium loads (≤30 tons), and no intense vibrations. Q345 steel, by contrast, features high tensile strength, good toughness, and superior fatigue resistance, which adapts to outdoor humid environments, heavy loads (≥30 tons), low temperatures, or high-frequency vibration locations, such as steel mills and ports.

A key mistake in material selection is blindly choosing high-grade steel. If the environment is dry and the load is moderate, Q235 steel fully meets the requirements, and excessive pursuit of Q345 steel will only increase costs. Conversely, using Q235 steel in heavy-load or harsh environments may lead to premature structural aging or potential safety hazards. In addition, special environments such as coastal areas and chemical plants require consideration of anti-corrosion treatment—galvanized steel or weathering steel can be selected to prevent corrosion from compromising structural safety.

Related Further Reading

Fabrication and Installation of Steel Structure Crane Beams

Detailed issues in the manufacturing and installation stages are the primary causes of long-term failures in crane beams. Below, we focus on common quality pitfalls in the industry, break down key control points, and help you avoid hidden problems.

Key Fabrication Control Points for Industrial Steel Crane Beams

Blanking precision directly influences subsequent assembly and structural reliability. Excessive dimensional errors during steel cutting result in uneven splicing gaps for the girder body, which in turn compromises weld integrity and overall load-bearing performance. Fabricators should utilize CNC cutting equipment to maintain a dimensional tolerance of ≤±2mm and conduct pre-assembly inspections before formal splicing.

Welding quality stands as a critical factor for structural safety. Defects such as incomplete penetration and weld cracks can drastically reduce the connection strength of crane rail support components. It is essential to select welding electrodes or wires compatible with the base metal, employ high-quality processes like submerged arc welding, and implement 100% non-destructive testing (e.g., ultrasonic NDT) after welding.

Thorough corrosion protection is key to extending the service life of crane components. Incomplete rust removal and insufficient coating thickness can accelerate the degradation of structural steel over time. Shot blasting should be used for rust removal (achieving Sa2.5 grade), and the coating thickness must be maintained at ≥120μm with uniform application across all surfaces and no missed areas.

Precision Installation Guidelines for Structural Steel Crane Beams

Three common issues arise during installation. First, support point elevation deviation: inconsistent column top heights cause uneven force distribution and abnormal deflection. Recheck elevations pre-installation, limiting deviation to ± 3mm. Second, excessive flatness/straightness errors: uneven beam tops or non-parallel axes lead to crane jams and wheel wear. Adjust with levels/theodolites (flatness ≤ 2mm/m, straightness ≤ 5mm full length). Third, improper fixing: loose bolts or poor welding cause instability. Ensure high-strength bolt torque meets design standards, welds are full, and conduct post-installation load testing to verify stability.

About K-HOME

——Pre Engineered steel Building Manufacturers China

Henan K-home Steel Structure Co., Ltd is located in Xinxiang, Henan Province. Established in the year 2007, registered capital of RMB 20 million, covering an area of 100,000.00 square meters with 260 employees. We are engaged in prefabricated building design, project budget, fabrication, installation of steel structure and sandwich panels with second-grade general contracting qualification.

Steel Structure Crane Beam Maintenance Practical Life-Extending Tips

Centered on actionable maintenance for steel structure crane beams, we outline specific, directly applicable preservation methods while abandoning formalistic procedures. From daily inspections, hidden hazard identification to targeted protection, it fully ensures operational safety and effectively extends the service life of the crane beams.

▪ Scenario-Based Steel Structure Crane Beam Inspection Schedule & Priority Checks

To ensure optimal performance, steel crane beam maintenance frequency should align with your operating environment. For indoor dry and light-load facilities, schedule inspections every 3 months; indoor heavy-load settings require monthly checks; and outdoor, high-frequency operation, or humid conditions demand biweekly inspections to catch issues early.

Inspection priorities vary by scenario: For light-load applications, focus on bolt tightness and surface rust formation. Heavy-load environments need thorough checks for weld cracks, crane beam deflection, and lateral support stability—critical for preventing structural failure. Outdoor crane beams require extra attention to anti-corrosion coating peeling and track wear, as exposure to elements accelerates degradation.

Support inspections with professional tools like magnifying glasses (for weld cracks), levels (for deflection checks), and torque wrenches (for bolt tightness). Adapt to seasonal changes: Reinforce bolts in low winter temperatures to stop crack propagation, clean surface dust promptly during summer’s high heat and humidity (to prevent corrosion), and clear drainage systems before the rainy season to avoid water-induced bottom rust.

▪ Targeted Corrosion & Rust Prevention Techniques for Steel Structure Crane Beams

Anti-corrosion and rust prevention shall be handled according to the degree of corrosion: for mild corrosion (surface rust), grind to remove rust first, then touch up with anti-rust paint and topcoat; for moderate corrosion (rust penetrating the steel surface), sandblasting shall be adopted for rust removal, followed by reapplication of primer, intermediate coat, and topcoat; for severe corrosion (pitting on the steel), conduct structural strength assessment first—replace components if strength is insufficient, and carry out sandblasting for rust removal and anti-corrosion treatment after meeting the standards.

For outdoor or high-humidity environments, dual protection of galvanization + painting can be adopted, or weathering steel can be directly selected. For dusty workshop environments, regularly clean the dust on the surface of steel structure crane beams to avoid accelerated corrosion due to accumulation. The key to anti-corrosion lies in thorough rust removal and ensuring coating thickness, rather than frequent repeated painting.

▪ Load Control & Usage Habit Optimization for Steel Crane Beam

Rational use is the key to extending the service life of steel crane beams: strictly comply with load limits, prohibit overloading operations, avoid impactful hoisting behaviors such as sudden start/stop of cranes and sudden dropping of heavy objects, to reduce the impact of dynamic loads on the beam body; take balancing measures when hoisting eccentric loads to prevent the beam body from bearing additional torque; regularly inspect crane wheels—promptly adjust or replace them if uneven wear or track irregularities occur to prevent local damage to the crane beam track. In addition, it is prohibited to pile debris on steel structure crane beams or conduct unrelated welding operations to avoid damaging the beam structure and anti-corrosion coating.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.