Warehouse construction is a systematic engineering project that involves project planning, structural design, construction organization, and later-stage operation. For manufacturers, logistics providers, retailers, and third-party warehousing companies, a structurally sound, functionally optimized, and expandable warehouse is one of the most important pieces of infrastructure in the supply-chain system.

As a professional supplier of steel warehouse buildings, we regularly participate in domestic and international warehousing projects and have accumulated comprehensive practical experience from preliminary planning to on-site delivery. This article systematically outlines the construction process of steel-structure warehouses to help companies form informed decisions during the planning phase.

Define Warehouse Purpose and Functional Requirements

The project’s starting point is clarifying the warehouse’s operational purpose and business objectives. Different warehouse structure types impose different requirements on layout, structural strength, environmental control, and IT/automation systems.

Typical categories include ordinary storage warehouses, which prioritize rack configuration and aisle widths to maximize storage efficiency; distribution centers (DCs), which emphasize high throughput and integration with automated sorting and conveying systems; cold-chain facilities, which demand stringent thermal insulation, condensation control, and energy-efficient refrigeration systems; cross-border e-commerce and third-party logistics (3PL) centers, which require flexible zoning, customs handling considerations, and robust information systems; and specialized warehouses for raw materials or hazardous goods, which must satisfy fire protection, explosion prevention, and environmental regulations.

Accurately defining the warehouse type at the project’s outset informs decisions such as building footprint, clear height, floor load capacity, fire rating, insulation strategy, and the overall investment envelope—thereby reducing the risk of redesign or scope creep later.

Site and Ground Condition Assessment

Site selection and site assessment for a steel warehouse are crucial to construction costs and operational efficiency. The assessment should cover the following:

- Geotechnical conditions: Conduct a professional ground investigation to determine bearing capacity, soil stratigraphy, groundwater level, and overall stability. Soft or compressible soils require pile foundations or ground improvement measures to ensure structural safety.

- Drainage and topography: Ensure the site has adequate drainage and proper grading to avoid foundation saturation during heavy rain. For low-lying sites, design of perimeter drains, interceptor channels, and sump systems may be necessary.

- Traffic and logistics flows: The site layout must accommodate large trucks, provide sufficient loading/unloading areas, turning radii, and parking, and design circulation routes to minimize congestion and safety risks.

- Expansion and planning coordination: Reserve space for future expansions or equipment upgrades, and ensure compatibility with local land-use plans and regulatory requirements.

In addition, climate and natural environment parameters are critical inputs for structural and envelope design. Design teams must obtain reliable local climate data, including:

- Annual and design-storm rainfall intensity (roof and drainage design)

- Maximum snow loads and seasonal snowfall depth (roof structure sizing)

- Design wind speed and prevailing wind directions (wind bracing and fasteners)

- Temperature and humidity ranges (insulation, condensation control, and HVAC sizing)

Seismic intensity or seismic zone classification (earthquake-resistant detailing and ductile connections) For example, in high-wind areas the roof and cladding must include uplift-resistant connections and additional bracing; in heavy-snow regions roof geometry and purlin spacing must account for snow loads; in seismically active zones the steel structure requires ductile nodes and seismic detailing. A thorough understanding of these geotechnical and climatic constraints is essential to minimize later maintenance and safety risks.

Structural System and Material Selection

Steel structure has become the dominant structural system of modern warehouse buildings due to its performance advantages. Compared with conventional concrete systems, steel offers several practical benefits:

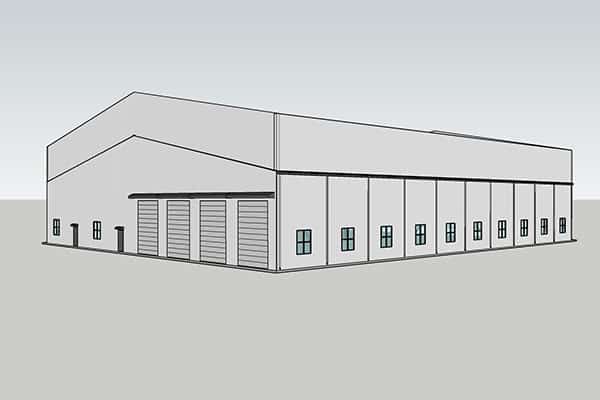

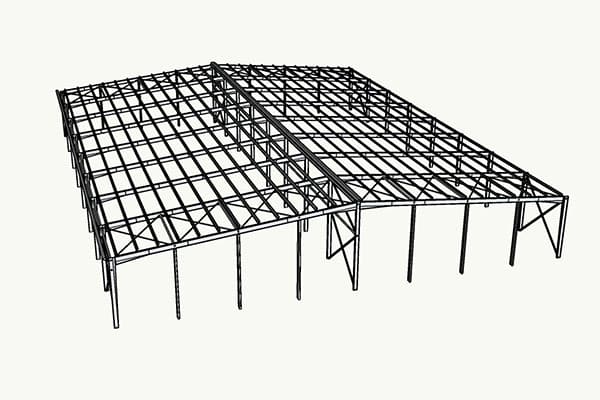

- High strength and long-span capability: steel can achieve large clear spans (typically 30–100 meters) with minimal internal columns, supporting high pallet racking, automated equipment, and forklift circulation.

- Shorter construction schedule: components are prefabricated off-site under factory quality control; on-site assembly with bolted connections reduces overall construction time by 30–50% compared to cast-in-place alternatives.

- Durability and maintenance: contemporary steel members are treated with hot-dip galvanizing or protective coating systems, extending service life and lengthening maintenance cycles.

- Environmental performance: steel is highly recyclable and supports sustainable construction targets, with lower waste generation during erection.

- Flexibility for future modification: bolted steel connections and modular members facilitate later reconfiguration, additions, or height increases.

Given these factors, steel structures generally represent the optimal balance of cost, schedule, and long-term operational flexibility for warehouse projects. Where additional fire resistance or thermal performance is required, steel frames are typically combined with passive fire protection measures and composite insulated cladding systems to meet code and operational targets.

Quotation and Contract Negotiation Process

Warehouse project pricing does not reduce to a simple “area × unit price” formula. To provide clients with transparent, feasible proposals, our typical service flow includes:

- Project information collection: client supplies project location, intended use, zoning of functions, and dimensional requirements.

- Preliminary layout and concept sketch: we prepare an initial arrangement and structural concept that accounts for local loads (wind, snow, seismic) and operational flows.

- Detailed quotation package: line-item pricing is produced based on building area, material grades, envelope type (EPS, PU, PIR insulated panels), doors and dock equipment, and required MEP systems.

- Client review and optimization: clients may request adjustments; we respond with value engineering options to optimize cost and constructability.

- Production and shop drawings: upon confirmation, we issue production drawings for steel fabrication and cladding components.

- Erection drawings and technical support: after manufacturing, we provide installation drawings, erection sequences, and remote or on-site technical assistance as required.

As a steel warehouse manufacturer, K-HOME provides an end-to-end workflow covering design, quotation, fabrication, and installation. We ensure traceability and quality control throughout the entire project lifecycle.

Detailed Design, Approvals, and Shop Drawings

Following contract execution, the project enters detailed design and regulatory approval phases.

Our design team will refine the construction drawings based on these details, specifying component dimensions, connection points, anchor bolt positioning, and other data required for on-site construction, while also completing structural calculations. During this process, we will submit design documents that comply with regulations promptly, ensuring that construction permits and related approvals are obtained as quickly as possible.

High-quality construction drawings are an effective way to minimize late-stage drawing changes and on-site rework.

Construction and Installation

Construction is typically executed in coordinated stages:

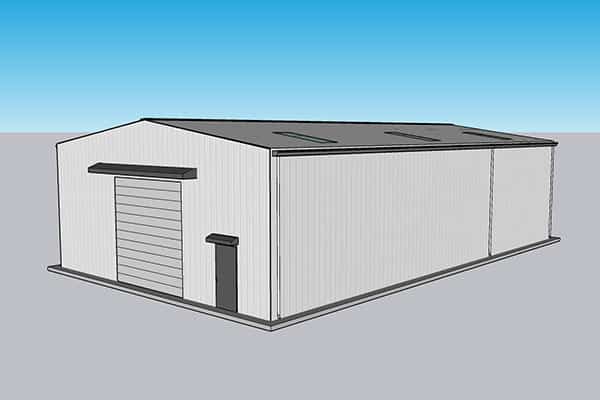

- Site preparation and foundations: site clearing, excavation, reinforcement, concrete pour, and precise installation of anchor bolts. Anchor bolt tolerance and verticality are critical for accurate column erection.

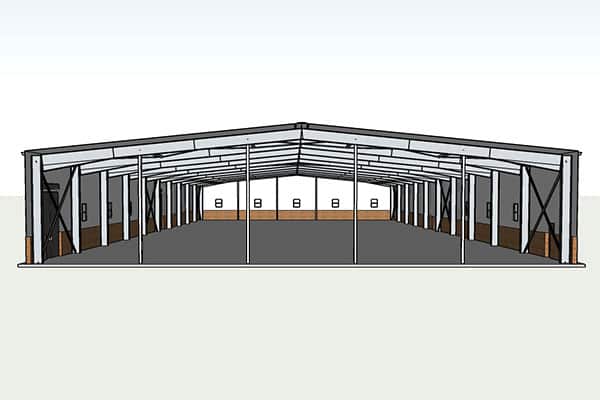

- Main structure erection: once foundations achieve design strength, prefabricated steel columns, rafters, and bracing are lifted and bolted into place in a planned erection sequence. This phase is often the most rapid and visible progress milestone.

- Envelope installation: roof panels, wall cladding, skylights, gutters, and doors are installed to produce a weather-tight building. The envelope must meet design criteria for waterproofing, wind resistance, and thermal performance.

- Interior systems construction: electrical distribution, lighting, plumbing, HVAC, fire protection (sprinkler) systems, security, and IT cabling are installed and commissioned in coordination with equipment placement.

- Finishes and commissioning: floor treatment, paint, hardware, racking bases, and final systems testing complete the scope, followed by commissioning and client acceptance tests.

About K-HOME

——Pre Engineered steel Building Manufacturers China

Henan K-home Steel Structure Co., Ltd is located in Xinxiang, Henan Province. Established in the year 2007, registered capital of RMB 20 million, covering an area of 100,000.00 square meters with 260 employees. We are engaged in prefabricated building design, project budget, fabrication, installation of steel structure and sandwich panels with second-grade general contracting qualification.

Design

Every designer in our team has at least 10 years of experience. You don’t have to worry about the unprofessional design affecting the safety of the building.

Mark and Transportation

In order to make you clear and reduce the site work, we meticulously mark each part with labels, and all parts will be planned in advance to reduce the number of packings for you

Manufacturing

Our factory has 2 production workshops with large production capacity and short delivery time. Generally, the lead time is around 15 days.

Detailed Installation

If this is the first time for you to install the steel building, our engineer will customize a 3D installation guide for you. You don’t need to worry about the installation.

why K-HOME Steel building?

As a professional steel building manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

related blog

related project

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.