Understanding the Role of Steel Structure Connections

Steel structure connections are an important technical means to ensure structural integrity and safety. By firmly connecting various components of steel buildings, they facilitate smooth load transfer and thereby maintain the overall stability of the steel structure.

These connection details integrate independent steel structural components — such as beams, columns, and trusses — into a cohesive, stable whole. Their design and construction quality directly affect the safety, durability, and performance of the building, making them an indispensable core link in steel construction. Whether for high-rise commercial buildings, industrial warehouses, or bridge projects, appropriate connection methods enable the steel framework to effectively resist various external forces such as gravity, wind, and seismic activity, ensuring the reliability of the building during long-term use.

Essentials of Steel Structure Connection Types

Common connection methods for steel structures include three main types: welded connections, bolted connections, and riveted connections.

Welded Connections: Strength and Integrity Design

Welded connections are a widely used connection method in steel structure buildings. By melting metal at high temperatures to fuse steel structural components, they achieve permanent joints that form nearly continuous monolithic nodes, exhibiting excellent strength and rigidity.

Common welding methods include butt welds and fillet welds: butt welds are used for end-to-end connections of components, while fillet welds are suitable for corner connections. Welded connections are extensively applied in factory-fabricated steel components, especially in scenarios with strict requirements for precision and load-bearing capacity. However, the welding process requires strict control of parameters to avoid issues such as residual stress, component deformation, or reduced strength in the heat-affected zone—these potential problems can impact the long-term service life of the structure.

Bolted Connections: Flexibility and Ease of Assembly

Bolted connections are another commonly used steel structure connection method, achieving connections between structural components through tightened bolts.

By securing steel structural components with bolts and nuts, bolted connections offer distinct advantages in terms of assembly convenience and reversibility. This connection method is particularly suitable for on-site construction, as it eliminates the need for specialized welding equipment, enabling quick adjustments to components and subsequent maintenance.

Bolted connections are mainly categorized into two types: ordinary bolted connections and high-strength bolted connections. Ordinary bolted connections transfer loads through friction and bearing capacity, while high-strength bolted connections provide higher load-bearing capacity—they form friction-resistant joints via preload and can withstand dynamic loads. In critical structures with high reliability requirements, such as bridges and mechanical equipment supports, high-strength bolted connections are widely adopted due to their excellent fatigue resistance.

Bolted Connections: Flexibility and Ease of Assembly

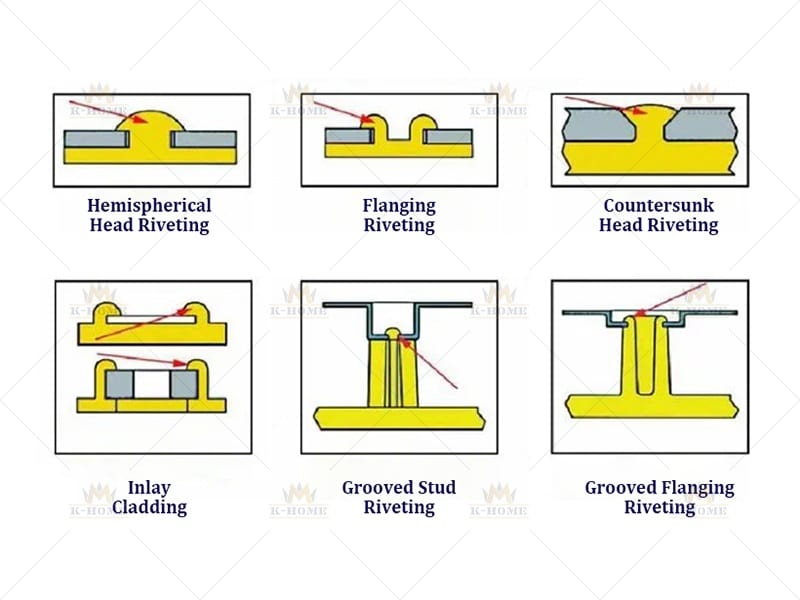

Riveted connections have a long application history in steel structural engineering and once served as the primary method for traditional steel structure connections. Although welding technology and high-strength bolts have become prevalent, the use of riveted connections in modern buildings has gradually declined due to their high labor intensity and low efficiency.

This connection method involves driving hot or cold rivets through pre-drilled holes in steel structural components, forming permanent joints through mechanical interlock. It boasts excellent durability and fatigue resistance, and was once widely used in heavy-duty structures such as old bridges and industrial workshops. However, the construction process of riveted connections requires high labor intensity and extremely precise hole alignment, which has led to their gradual replacement by more efficient connection methods in modern efficiency-oriented construction.

Further Related Reading: Steel Structure Introduction & Design & Installation

Applications and Practical Recommendations for Steel Structure Connections

The application effect of steel structure connections depends on selecting a suitable connection type in the early stage, as well as standardized operations during construction and maintenance management in long-term use. These links form an effective implementation path for steel structure connections, directly affecting the structural safety, stability, and actual service life of the building.

Whether it is the connection of factory-fabricated components or the on-site assembly of joint connections, operations must be carried out in accordance with scientific requirements based on specific scenarios. At the same time, a sound quality control and maintenance mechanism should be established to ensure that connection nodes always maintain a reliable condition.

How to Choose the Right Steel Structure Connection Type for Steel Buildings?

The selection of steel structure connection methods requires making decisions after conducting objective and rational analysis, based on the actual project conditions and comprehensively considering key influencing factors such as structural requirements, load conditions, environmental factors, and construction conditions.

- Structural requirements: High-rise buildings need to withstand wind or seismic deformation, and the ductility of high-strength bolted connections can prevent brittle fracture; for buildings with stable stress conditions, such as small warehouses and office buildings, welded connections can balance compactness and load-bearing capacity.

- Load conditions: Residential buildings, ordinary office buildings, and similar structures are mainly subjected to static loads such as building dead weight and fixed equipment weight, where the rigidity, stability, and cost-effectiveness of welded connections can meet the requirements; industrial plants, warehouses, and other facilities need to bear dynamic loads such as mechanical equipment vibration and impact, and high-strength bolted connections offer superior fatigue resistance, maintaining connection reliability under repeated loading.

- Environmental factors: In corrosive environments such as coastal areas and industrial zones, bolted connections feature more flexible anti-corrosion treatment and convenient subsequent replacement, resulting in higher adaptability; in cold regions, temperature changes are prone to causing component contraction and expansion, and the flexibility of bolted connections can better adapt to such deformations, reducing joint stress concentration.

- Construction conditions: In remote areas, locations lacking welding resources, or projects with tight construction schedules, bolted connections have a simple assembly process and do not require complex equipment, which can improve construction efficiency; however, for components undergoing factory prefabrication, welded connections can be implemented in a standardized environment, making it easier to control precision and quality. After prefabrication, the components are transported to the site for installation, balancing both quality and schedule.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

Quality Control and Inspection of Prefabricated Steel Structure Connections

Regardless of the connection method adopted, strict quality control is crucial to ensuring structural safety. During the factory prefabrication stage, welders must hold relevant qualifications, welding materials need to be dried, and welding parameters should be monitored in real time to avoid defects; for bolted connection components, the processing accuracy of bolt holes must be guaranteed to ensure proper installation fit. During on-site construction, connection surfaces must be cleaned before welding; bolts should be tightened in sequence, and high-strength bolts must be operated with special torque wrenches according to specified preload requirements.

Inspection and acceptance methods should be selected based on specific needs: Ultrasonic testing is used for welded connections to detect internal defects, with radiographic testing supplemented for key parts, and re-inspection is required after defect repair. For bolted connections, sampling inspection of preload is conducted, along with checks on the number of exposed threads and connection tightness; in corrosive environments, regular verification of anti-corrosion coatings is necessary. During long-term use, regular inspections of connection nodes must be carried out, focusing on weld cracks, bolt loosening and corrosion, and coating damage. Potential issues such as corrosion and fatigue cracks should be identified and addressed promptly to prevent the escalation of safety hazards.

- Ultrasonic Testing of Steel Structure Welds

- Radiographic Testing of Steel Structures

- Visual Inspection of Welds for Quality Control

Need Help?

Please let me know your requirements, such as project location, usage, L*W*H, and additional options. Or we can make a quote based on your drawings.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.