In recent years, the urbanization process is getting faster and faster, and the prefabricated steel structure building industry has achieved unprecedented development. People have higher and higher requirements for the practicability and safety of buildings. In modern construction engineering, steel structure design has certain advantages, and its application in construction is becoming more and more extensive. Combined with years of work experience, K-home summed up 8 professional basic knowledge about steel structure, the content is long, please read it patiently:

1.The Characteristics Of Steel Structure:

- The steel structure has lightweight

- High reliability of steel structure work

- The steel has good vibration resistance (shock) and impact resistance

- The steel structure can be assembled accurately and quickly

- It is easy to make a sealed structure

- Steel structure is easy to corrode

- Poor fire resistance of steel structure

2. Grades And Properties Of Commonly Used Steel Structures

- Carbon structural steel: Q195, Q215, Q235, Q255, Q275, etc.

- Low alloy high strength structural steel

- High-quality carbon structural steel and alloy structural steel

- Special purpose steel

3. Principles Of Material Selection For Steel Structures

The material selection principle of steel structure is to ensure the bearing capacity of the load-bearing structure and prevent brittle failure under certain conditions. It is comprehensively considered according to the importance of the structure, the load characteristics, the structural form, the stress state, the connection method, the thickness of the steel and the working environment. of.

The four steel types proposed in “Code for Design of Steel Structures” GB50017-2003 are the “appropriate” types and are the first choice when conditions permit. The use of other types is not prohibited, as long as the steel used meets the requirements of the specification.

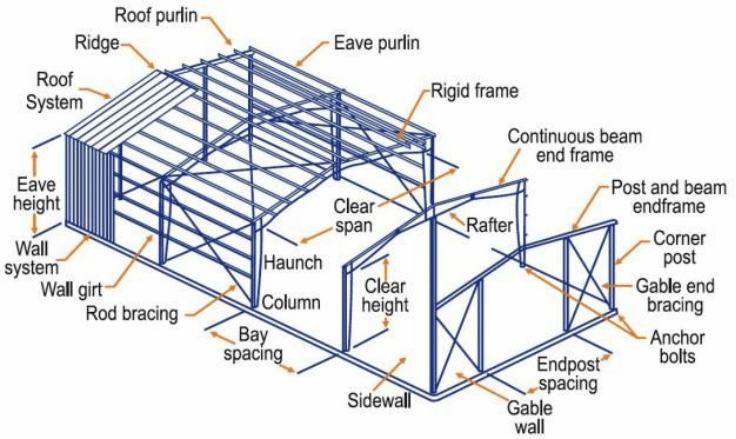

Fourth, the main technical content of steel structure:

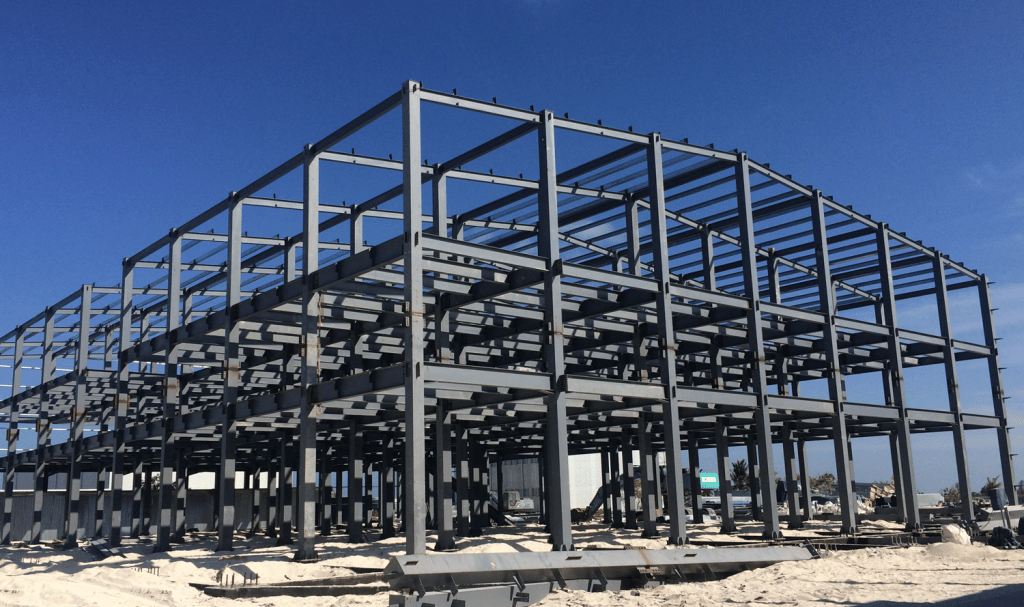

(a) High-rise steel structure technology. According to the building height and design requirements, the frame, frame support, cylinder and giant frame structure are respectively used, and the components can be steel, stiff reinforced concrete or steel tube concrete. The steel members are light and ductile, and can be welded or rolled, which is suitable for super high-rise buildings; stiff reinforced concrete members have high rigidity and good fire resistance, and are suitable for medium and high-rise buildings or bottom structures; steel pipe concrete is easy to construct, For column structures only.

(b) Space steel structure technology. The space steel structure has the advantages of being lightweight, high rigidity, beautiful appearance and fast construction speed. The ball joint flat grid, multi-layer variable-section grid and reticulated shell with a steel pipe as the rod are the structural types with the largest amount of space steel structure in my country. It has the advantages of large space rigidity and low steel consumption and can provide complete CAD in the design, construction and inspection procedures. In addition to the grid structure, there are also large-span suspension cable structures and cable-membrane structures in space structures.

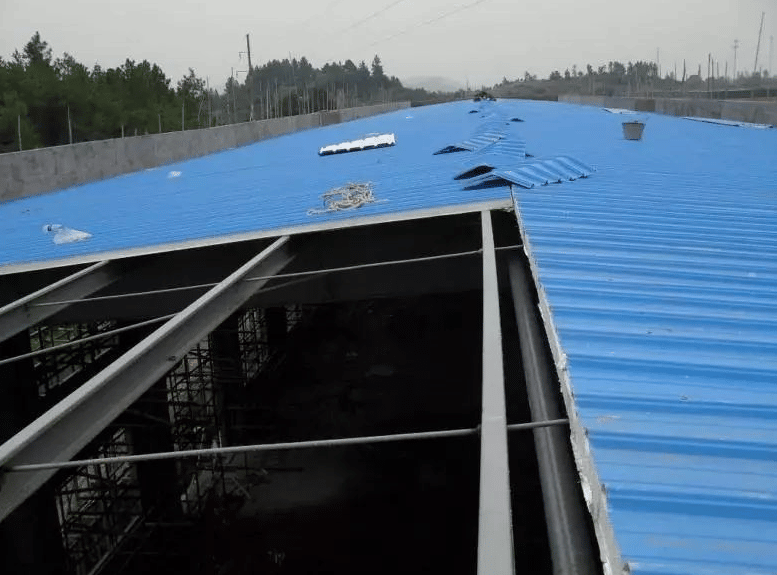

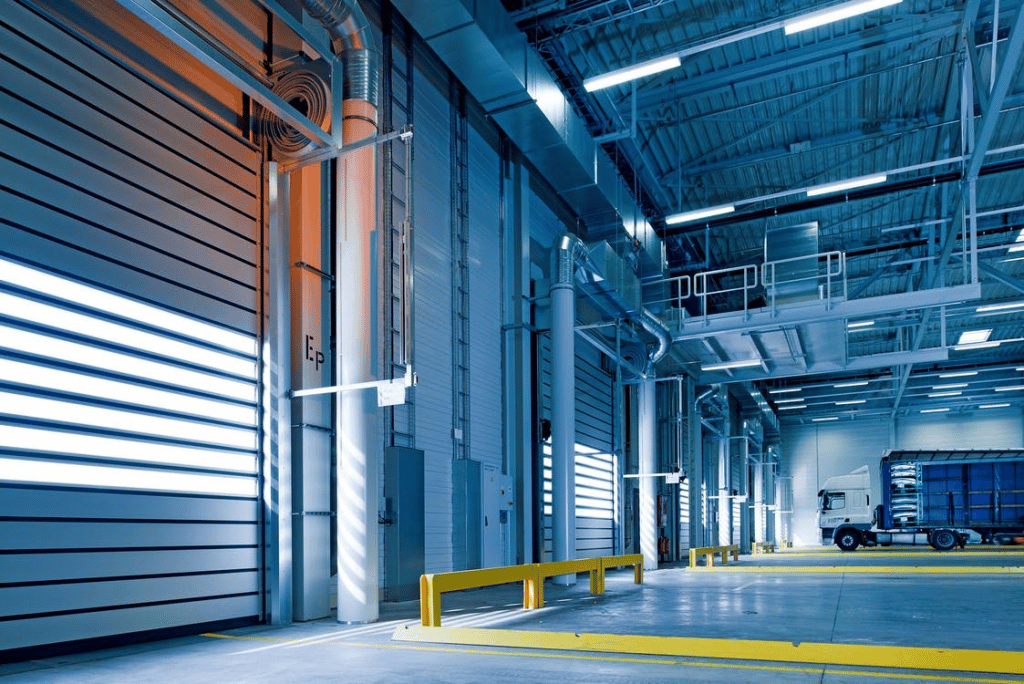

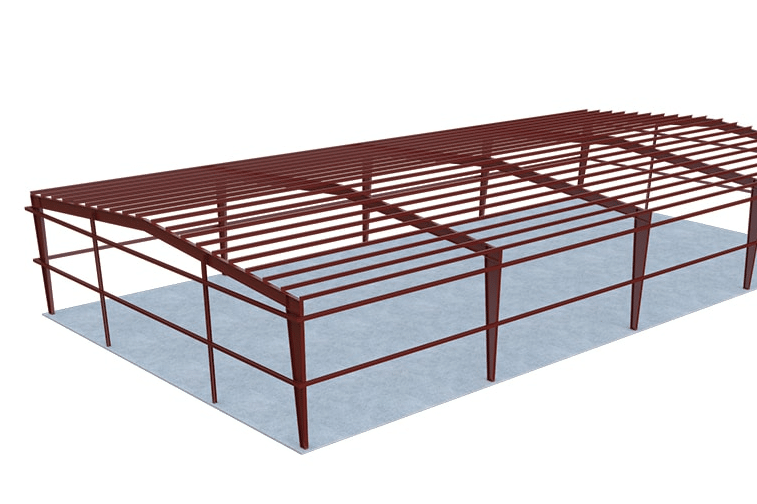

(c) Light steel structure technology. A new structural form consisting of walls and roof envelopes is made with light-colored steel plates. A light steel structure system composed of large-section thin-walled H-shaped steel wall beams and roof purlins welded or rolled by steel plates above 5mm, round steel made of flexible support systems and high-strength bolt connections. 30m or more, the height can reach more than ten meters, and light cranes can be set up. The amount of steel used is 20-30kg/m2. Now there are standardized design procedures and specialized production enterprises, with good product quality, fast installation speed, lightweight, low investment, and construction is not limited by seasons, suitable for all kinds of light industrial plants.

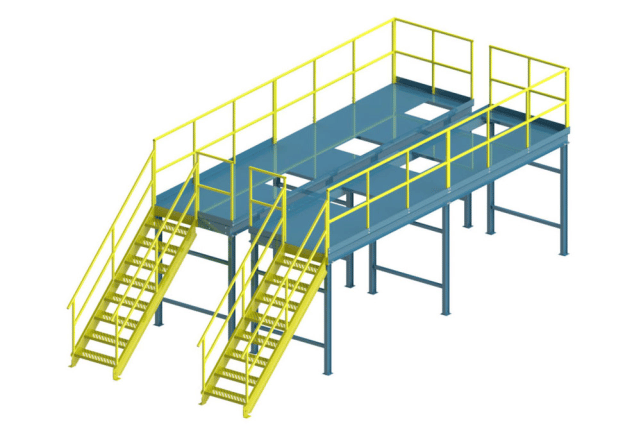

(d) Steel-concrete composite structure technology. The beam and column load-bearing structure composed of section steel or steel management and concrete components is a steel-concrete composite structure, and its application range has been expanding in recent years. The composite structure has the advantages of both steel and concrete, with high overall strength, good rigidity, and good seismic performance. When the outer concrete structure is used, it has better fire resistance and corrosion resistance. Combined structural members can generally reduce the amount of steel by 15 to 20%. The composite floor and concrete-filled steel tubular components also have the advantages of less or no formwork, convenient and fast construction, and great promotion potential. It is suitable for frame beams, columns and floors of multi-story or high-rise buildings with large loads, industrial building columns and floors, etc.

(e) High-strength bolt connection and welding technology. High-strength bolts transmit stress through friction and are composed of three parts: bolts, nuts and washers. The high-strength bolt connection has the advantages of simple construction, flexible dismantling, high bearing capacity, good fatigue resistance and self-locking, and high safety. It has replaced riveting and partial welding in the project and has become the main connection method in the production and installation of steel structures. For steel components and thick plates made in the workshop, automatic multi-wire arc submerged welding should be used, and the box-column clapboard should use melting nozzle electro slag welding and other technologies. In the field installation and construction, semi-automatic welding technology, gas-shielded flux-cored welding wire and self-shielded flux-cored welding wire technology should be used.

(f) Steel structure protection technology. The protection of steel structures includes fire prevention, anti-corrosion and rust prevention. Generally, it is not necessary to do anti-rust treatment after the fire-retardant coating treatment, but it still needs to be anti-corrosion treatment in buildings with corrosive gas. There are many types of domestic fire retardant coatings, such as TN series, MC-10, etc. Among them, MC-10 fire retardant coatings include alkyd enamel paint, chlorinated rubber paint, fluororubber paint and chlorosulfonated paint. In the construction, the appropriate coating and coating thickness should be selected according to the steel structure type, fire resistance grade requirements and environmental requirements.

5. Objectives And Measures Of Steel Structure:

Steel structure engineering involves a wide range of technical difficulties and must follow national and industry standards in its promotion and application. Local construction administrative departments should pay attention to the construction of the specialization stage of steel structure engineering, organize the training of quality inspection teams, and summarize work practices and new technology applications in a timely manner. Colleges and universities, design departments and construction enterprises should accelerate the training of steel structure engineering technicians and promote the mature technology of steel structure CAD. The mass academic group should cooperate with the development of steel structure technology, carry out extensive academic exchanges and training activities at home and abroad, and actively improve the overall level of steel structure design, production, construction and installation technology, and can be rewarded in the near future.

6. The Connection Method Of Steel Structure

There are three types of connection methods for steel structures: weld connection, bolt connection and rivet connection.

(a), Welding Seam Connection

The welding seam connection is to partially melt the electrode and the weldment by the heat generated by the arc, and then condense into a weld after cooling, so as to connect the weldment as a whole.

Advantages: no weakening of component section, saving of steel, simple structure, convenient manufacturing, high connection rigidity, good sealing performance, easy to use automatic operation under certain conditions, and high production efficiency.

Disadvantages: The heat-affected zone of the steel near the weld due to the high temperature of welding may be brittle in some parts; during the welding process, the steel is subjected to unevenly distributed high temperature and cooling, resulting in welding residual stress and residual deformation of the structure. Bearing capacity, stiffness and performance have a certain impact; due to the high stiffness of the welded structure, local cracks are easy to expand to the whole once they occur, especially at low temperatures. Defects may occur that reduce fatigue strength.

(b), Bolt Connection

Bolted connection is to connect the connectors into one body through bolts, such as fasteners. There are two types of bolted connections: ordinary bolted connections and high-strength bolted connections.

Advantages: simple construction process and convenient installation, especially suitable for site installation and connection, and easy to disassemble, suitable for structures that require assembly and disassembly and temporary connections.

Disadvantages: It is necessary to open holes on the plate and align the holes when assembling, which increases the manufacturing workload and requires high manufacturing accuracy; the bolt holes also weaken the cross-section of the components, and the connected parts often need to overlap each other or add auxiliary connections. Plate (or angle steel), so the structure is more complicated and it costs more steel.

(c), Rivet Connection

The rivet connection is a rivet with a semi-circular prefabricated head at one end, and the nail rod is quickly inserted into the nail hole of the connecting piece after burning red, and then the other end is riveted into a nail head with a rivet gun to make the connection tight. solid.

Advantages: riveted force transmission is reliable, plasticity and toughness are good, quality is easy to check and guarantee, and it can be used for heavy and directly bearing dynamic load structures.

Disadvantages: The riveting process is complicated, the manufacturing cost is labor and material, and the labor intensity is high, so it has been basically replaced by welding and high-strength bolt connections.

Types Of Connections In Steel Structures

7. Welding Connection

(a) Welding Method

The commonly used welding method for steel structures is arc welding, including manual arc welding, automatic or semi-automatic arc welding, and gas shielded welding.

Manual arc welding is the most commonly used welding method in steel structures, with simple equipment and flexible and convenient operation. However, the labor conditions are poor, the production efficiency is lower than that of automatic or semi-automatic welding, and the variability of weld quality is large, which depends to a certain extent on the technical level of the welder.

The weld quality of automatic welding is stable, the internal defects of the weld are less, the plasticity is good, and the impact toughness is good, which is suitable for welding long direct welds. Semi-automatic welding is suitable for welding curves or welds of any shape due to manual operation. Automatic and semi-automatic welding should use welding wire and flux suitable for the main metal, the welding wire should meet the requirements of national standards, and the flux should be determined according to the welding process requirements.

Gas shielded welding uses inert gas (or CO2) gas as the protective medium of the arc to isolate the molten metal from the air to keep the welding process stable. The arc heating of gas shielded welding is concentrated, the welding speed is fast, and the penetration depth is large, so the strength of the weld is higher than that of manual welding. And good plasticity and corrosion resistance, suitable for the welding of thick steel plates.

(b), The Form Of The Weld

The welding seam connection form can be divided into four forms: butt joint, lap joint, T-shaped joint and fillet joint according to the mutual position of the connected components. The welds used for these connections are in two basic forms, butt welds and fillet welds. In the specific application, it should be selected according to the force of the connection, combined with the manufacturing, installation and welding conditions.

(c) Weld Structure

1. Buttweld

Butt welds transmit force directly, smoothly, and have no significant stress concentration, so they have good mechanical performance and are suitable for the connection of components bearing static and dynamic loads. However, due to the high-quality requirements of butt welds, the welding gap between weldments is strict, and it is generally used in factory-made connections.

2. Fillet weld

The form of fillet welds: fillet welds can be divided into side fillet welds parallel to the force acting direction and front fillet welds perpendicular to the force acting direction and obliquely intersecting the force acting direction according to their length direction and the direction of external force action. slanted fillet welds and surrounding welds.

The cross-sectional form of fillet weld is divided into ordinary type, flat slope type and deep penetration type. The hf in the figure is called the fillet size of the fillet weld. The ratio of the leg side of the ordinary section is 1:1, which is similar to an isosceles right triangle, and the force transmission line is bent more violently, so the stress concentration is serious. For the structure directly bearing the dynamic load, in order to make the force transmission smooth, the front fillet weld should adopt the flat slope type with the size ratio of the two fillet edges 1:1.5 (the long side should follow the direction of the internal force), and the side fillet weld should adopt the ratio of 1. : 1 deep penetration.

8. Bolt Connection

(a). The Structure Of Ordinary Bolt Connection

The Form And Specification Of Ordinary Bolts

The common form used by the steel structure is the large hexagonal head type, and its code is represented by the letter M and the nominal and diameter (mm). M18, M20, M22, M24 are commonly used in engineering. According to international standards, bolts are uniformly represented by their performance grades, such as “grade 4.6”, “grade 8.8” and so on. The number before the decimal point indicates the minimum tensile strength of the bolt material, such as “4” for 400N/mm2 and “8” for 800N/mm2. The numbers after the decimal point (0.6, 0.8) indicate the yield ratio of the bolt material, that is, the ratio of the yield point to the minimum tensile strength.

According to the machining accuracy of bolts, ordinary bolts are divided into three levels: A, B, and C.

A and B-grade bolts (refined bolts) are made of 8.8-grade steel, turned by machine tools, with smooth surfaces and accurate dimensions, and are equipped with class I holes (that is, the bolt holes are drilled or expanded on the assembled components. , the hole wall is smooth, and the hole is accurate). Because of its high machining accuracy, close contact with the hole wall, small connection deformation, and good mechanical performance, it can be used for connections with large shear and tensile forces. However, it is more labor-intensive and costly to manufacture and install, so it is less used in steel structures.

Grade C bolts (rough bolts) are made of grade 4.6 or 4.8 steel, rough processing, and the size is not accurate enough. Only type II holes are required (that is, the bolt holes are punched on a single part at one time or drilled without a drill. Generally, the hole diameter is larger than that of bolts. The rod diameter is 1~2mm larger). When the shear force is transmitted, the connection deformation is large, but the performance of transmitting the tensile force is still good, the operation does not require special equipment, and the cost is low. Commonly used for bolted connections in tension and secondary shear connections in structures that are statically or indirectly dynamically loaded.

Arrangement Of Ordinary Bolted Connections

The arrangement of bolts should be simple, uniform and compact, to meet the force requirements, and the structure should be reasonable and easy to install. There are two types of arrangement: side-by-side and staggered (as shown in the figure). The parallel is simpler, and staggered is more compact.

(B). The Stress Characteristics Of Ordinary Bolted Connections

- Shear bolt connection

- Tension bolt connection

- Pull-shear bolt connection

(C). The Stress Characteristics Of High-Strength Bolts

High-strength bolted connections can be divided into friction type and pressure type according to design and force requirements. When the frictional connection is subjected to shearing, the maximum frictional resistance may occur between the plates when the external shear force reaches the limit state; when the relative slip occurs between the plates, it is considered that the connection has failed and is damaged. When the pressure-bearing connection is sheared, the friction force is allowed to be overcome and the relative slip between the plates occurs, and then the external force can continue to increase, and the ultimate failure of the screw shearing or the hole wall bearing pressure is the limit state.

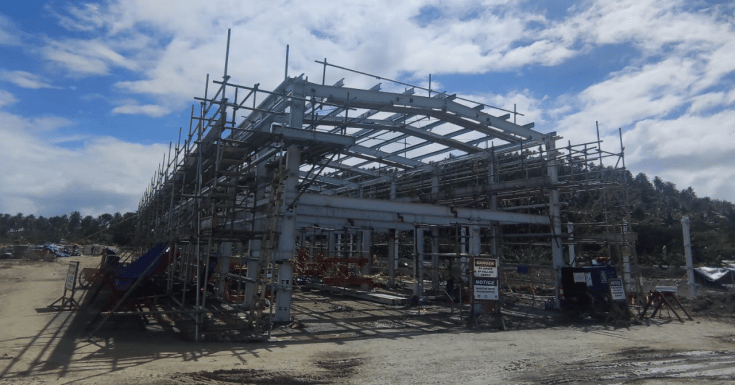

Henan Steel Structure Engineering Technology Co., Ltd. specializes in the construction of steel structure workshops, warehouses, workshops and other projects, and can provide quotations, renderings, installation drawings and other services according to the budget. For more questions, please consult our professional team.

Recommended Reading

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.