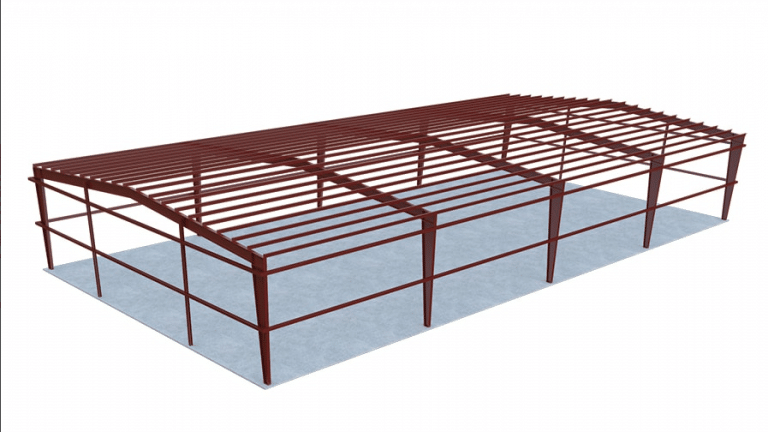

Steel Workshop Building With Crane

essential Beginner’s Intro to Steel Workshop with Crane

A steel workshop building with a crane is an industrial building that integrates a crane system based on a steel structure, and can meet the needs of production operations and heavy-load lifting in one stop within the same area. For those new to the industry or unfamiliar with such workshops, understanding their features clearly will help them grasp their practical role and value in industrial scenarios.

What is A Steel Workshop Building With Cranes?

A steel workshop building with a crane is essentially an industrial structure that takes a steel frame as its main body while integrating a dedicated crane system. Its core advantage lies in the synergy between the steel structure and the integrated crane: the steel frame primarily bears the weight of the entire workshop, guaranteeing the building’s overall stability; meanwhile, the built-in crane can directly lift and move heavy loads inside the workshop. This eliminates the need to deploy additional external lifting equipment, effectively saving time and reducing costs in daily production.

In industrial settings, this type of steel workshop building with a crane meets two key needs efficiently: production operations and heavy object handling. It is not a simple mix of a regular workshop and a standalone crane. Instead, the integration of the steel structure and crane is carefully planned from the design stage—this ensures the forces from the crane’s operation fully match the steel structure’s load-bearing capacity, preventing potential safety hazards in long-term use.

What Are the 4 Main Types of Steel Workshop Buildings With Crane?

Steel workshop buildings with cranes are mainly classified by the type of integrated cranes, with four common categories—each differing in structural features and applicable scenarios to better fit specific industrial needs.

- Steel Workshop with Overhead Crane

- Steel Workshop with Gantry Crane

- Steel Workshop with Suspension Crane

- Steel Structure Workshop with Jib Crane

Critical Design Specifications for Steel Workshop Building With Crane

Designing a steel structure workshop with a crane requires strict adherence to the following key specifications, both to ensure safety in use and to make sure the workshop meets actual production needs.

Load-bearing design must calculate total weight (including the workshop steel structure, crane, and maximum lifted loads) and account for external loads like wind, snow, and earthquakes. In northern regions, maximum snow weight must be included to prevent roof damage; steel beams in crane areas need 30% higher load capacity than other areas to avoid bending.

Crane rails must match crane parameters to bear wheel pressure and prevent deformation. Rail spacing must align with crane span, with an error within ±3mm to avoid operational jams. Steel beams under rails need reinforcing ribs to boost local load capacity and prevent rail sinking.

Workshop height and width must reserve sufficient space for the crane: when lifting loads, at least 50cm clearance is needed between the load top and the roof to avoid collisions. The workshop width should be 1-2 meters larger than the crane span to prevent edge-lifting collisions with columns, while leaving space for equipment and operations.

Safety protection requires targeted devices: limit switches at crane operation ends to prevent accidental collisions with columns; guardrails at high points (e.g., platforms, walkways) to avoid falls. In dusty or corrosive environments, steel structures need anti-corrosion and dust-proof treatment, and crane motors require protective covers to reduce environmental wear and extend service life.

What Core Industries Need a Steel Workshop Building With Crane?

For many industrial sectors, a steel workshop building with a crane is not an optional configuration, but a core facility that ensures smooth production operations. Without it, many daily tasks struggle to run efficiently. These industries often face material handling challenges in production, and a steel workshop with an integrated crane is precisely an industry necessity—it solves the practical heavy-lifting problems in their manufacturing processes:

- Mechanical Manufacturing Industry: Needs to move heavy parts (5+ tons, e.g., machine tool bases, engine blocks). Forklifts are slow and risk damaging parts. A steel workshop with an integrated crane lifts parts directly to assembly areas, saving time and protecting components.

- Automotive Manufacturing Industry: Requires heavy lifting throughout production (e.g., car bodies, engines, transmissions). External lifting equipment causes costly production line halts. A steel workshop building with a crane provides on-demand lifting, keeping lines running continuously.

- Logistics & Warehousing Industry: Handles steel materials and large crates (for high-shelf storage or truck unloading). Rented mobile cranes add costs and delays. A workshop with a built-in crane eliminates rental fees and accelerates cargo turnover.

- Heavy Industry Sector: Moves ultra-heavy parts (tens to hundreds of tons, e.g., steelmaking furnaces, crushers) that ordinary workshops can’t lift. A steel-structured workshop with a crane offers strong load-bearing and lifting capabilities to complete assembly.

- Precision Machining Industry: Transports precision molds and CNC spindles—parts sensitive to misalignment (which ruins accuracy). Manual handling often causes deviations. A steel workshop with suspension/jib cranes enables precise lifting, ensuring qualified machining results.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18790630368), or send an e-mail (sales@khomechina.com) to leave your contact information. We will contact you as soon as possible.

Must-Know Factors for Choosing a Steel Workshop Building With Crane

When selecting a steel workshop building with a crane, you must start from your actual needs. The core is to check if it fits your daily production scenarios—especially aligning with the workshop’s operational rhythm. Blind choices often lead to issues, and this directly impacts the reliability and cost-effectiveness of long-term use.

- Clarify Lifting Requirements: First, confirm the maximum lifting weight, lifting height, and lifting range. For example, if you need to lift up to 8-ton loads daily, choose a 10-ton crane to reserve load capacity and avoid insufficient capacity later. If lifting to a 5-meter height is required, the workshop’s clear height must exceed 6 meters—this leaves space for the crane’s own structure and prevents collisions with the roof during lifting. For full-workshop coverage, opt for an overhead crane; for local-area lifting only, use a jib crane to avoid resource waste.

- Determine Workshop Dimensions: Set dimensions based on production and storage needs. For instance, if your parts are 10 meters long, the workshop should be over 15 meters long to include storage and movement space. If 2 production lines are needed, the width must fit both equipment placement and crane operation—avoid blindly pursuing excessive space.

- Adapt to the Usage Environment: In humid areas, select corrosion-resistant steel and waterproof motors. In dusty environments, add protective covers for the crane and dust-proof nets on the roof. In cold areas, use steel with good low-temperature toughness to reduce long-term wear and tear.

- Plan a Reasonable Budget: The budget should cover both construction costs (steel structure, crane, construction work) and long-term costs (maintenance, anti-corrosion). For example, a 10-ton crane is about 30% more expensive than 5-ton models; prioritize branded equipment to lower long-term maintenance fees.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

Steel Building Cost(Price Square Foot/Tonnage)

Many customers who use steel structures for the first time always ask how much the steel building prices per square meter are when they come up. How much does the…

Steel Buildings Design Solutions

This Guideline(instruction) is long. You could use the quick link below, and jump to the part you like. Components Select Relevant Components One of K-home’s customized building design processes is…

Introduction To Steel Portal Frame Building

Steel Portal Frame Building is a traditional structural system. The upper main frame of this type of structure includes rigid frame inclined beams, rigid frame columns, supports, purlins, tie rods,…