Welding is the most important connection mode in steel structures at present. It has the advantages of not weakening component sections, good rigidity, simple structure, convenient construction and automatic operation.

The function of connection is to combine steel plates or shaped steel into members in a certain way or combine several components into an overall structure, so as to ensure that they work together.

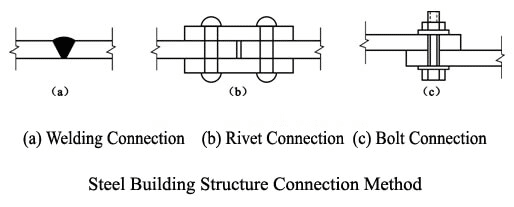

Steel structure connection methods: Welding, rivet and bolting connection.

Steel Building Structure connection-Welding

Welded connection is through the heat generated by the arc to make the electrode and welding parts local melting, after condensation weld, so as to connect the welding parts into one.

Advantages and disadvantages of the welded connection

Advantages:

- Does not weaken the component section, saving steel;

- Can be welded into any shape of the components, welding can be directly welded, generally do not need other connectors, simple components, manufacturing labor-saving;

- The tightness of the connection is good and the stiffness is large;

- Easy to use automation, high production efficiency.

Disadvantages:

- The material in the heat-affected zone near the weld becomes brittle;

- Welding residual stress and deformation are produced in the welding parts, which have adverse effects on the structure work.

- Welded structures are very sensitive to cracks. Once a local crack occurs, it may rapidly spread to the whole section, especially at low temperature, brittle fracture is easy to occur.

Further Reading: Structural Steel Welding & Welded Splice Joint in Steel Structure

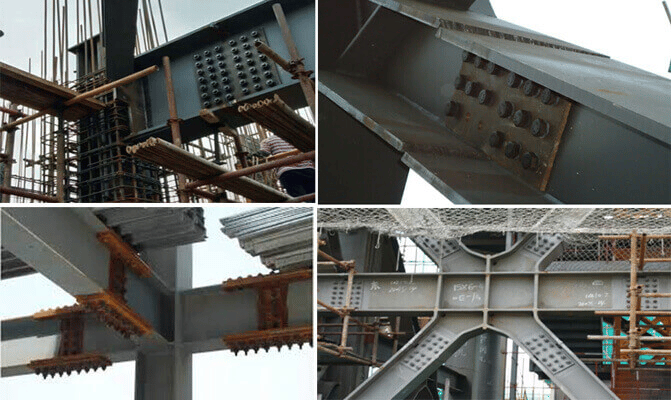

Steel Building Structure connection-Bolting

Bolting connection has the advantage of convenient installation, especially suitable for site installation and connection, but also easy to disassemble, suitable for the need to assemble and disassemble the structure and temporary connection. Its disadvantage is the need to pull on the hole and pile stupid hole, increasing the manufacturing workload; The bolt hole also weakens the section of the member, and the connecting plate needs to be overlapped with each other or add splicing plate or Angle steel and other connectors, so it costs more steel than welding connection.

Connect with ordinary bolts

According to the requirements of hole wall quality, the bolt holes are divided into two categories: class I holes (A, B) and class II holes (C).

The bolted connection of the type I hole has higher shear and bearing strength than that of Type II hole, but the manufacturing of Type I hole is laborious and costly.

Class A and B bolt holes have high requirements for hole making, but they are difficult to install and cost high, so they are rarely used. Class C bolt holes are rough and inaccurate, but easy to install. They are widely used in steel structures.

High strength bolts

The mechanism of shear force transfer by high-strength bolt connection is different from that of ordinary bolt connection. Ordinary bolt transfers shear force by bolt shear resistance and bearing pressure, while high-strength bolt connection transfers shear force by strong friction resistance between connected plates.

Installation through a special wrench, tighten the nut with large torque so that the screw has a large pre-tension. The pre-tension of the high-strength bolt clamps the connected parts so that the contact surface of the parts produces a great friction force, and the external force is transmitted by friction. This connection is called high strength bolt friction connection.

The performance of the bolt is expressed by the performance grade of the bolt, such as 4.6, 8.8, 10.9.

The number before the decimal point indicates the tensile strength of the bolt material, and the number after the decimal point indicates the flexural strength ratio.

The strength of class 4.6, 8.8 and 10.9 bolts belongs to 400N/mm2, 800N/mm2 and 1000N/mm2 respectively.

Class C bolts are 4.6 or 4.8 and are made of Q235 steel.

Grade A and B bolts are of grade 5.6 or 8.8 and are made of low alloy steel or after heat treatment.

High strength bolts are grade 8.8 or 10.9, made of 45 steel, 40B steel and 20MnTiB steel.

There are two types of calculations for high-strength bolted connections:

1. The friction connection only relies on the strong friction resistance between the connected plates to transmit the force, and the friction resistance has just been overcome as the limit state of the connection bearing capacity. Therefore, the shear deformation of the connection is small and the integrity is good.

2. Pressure type connection by the friction between the connecting plate and the bolt joint force, to the bolt shear or pressure (pressure) bad for the limit of the bearing capacity of the connection.

High-strength bolts are drilled into holes. Friction type connection, aperture than bolt nominal diameter 1.5-2.0mm, 1.0-1.5mm pressure type. In order to improve friction, the contact surfaces of the connection should also be treated.

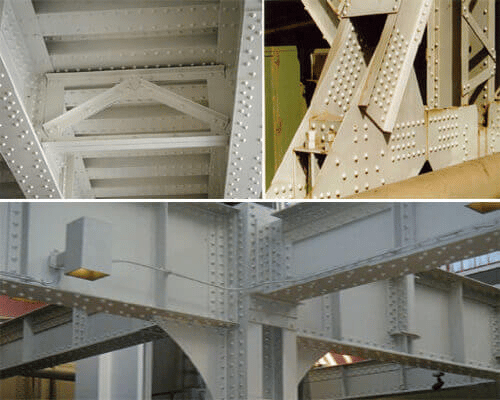

Steel Building Structure Connection-Rivet

Rivet connection is to make rivets with semicircular prefabricated nail head at one end, and quickly insert the nail rod into the nail hole of the connector after it is heated red, and then use a riveting gun to rivet the other end into a nail head to make the connection secure.

Advantages: reliable riveting force transmission, good plasticity, toughness, quality is easy to check and guarantee, can be used for heavy and directly bearing dynamic load structure.

Disadvantages: the riveting process is complex, the manufacturing cost of labor and materials, and high labor intensity, so it has been basically replaced by welding and high strength bolt connection.

The connection mode and its quality directly affect the working performance of the steel structure. The connection of steel structure must conform to the principles of safety and reliability, clear force transmission, simple structure, convenient manufacture and steel saving. The joint should be of sufficient strength and have sufficient space suitable for connection.

The PEB Steel Building

The Other Additional Attachments

Building FAQs

- How to Design Steel Building Components & Parts

- How Much Does a Steel Building Cost

- Pre-Construction Services

- What is a Steel Portal Framed Construction

- How to Read Structural Steel Drawings

Blogs Selected for You

- The Main Factors Affecting The Cost of Steel Structure Warehouse

- How Steel Buildings Help Reduce Environmental Impact

- How to Read Structural Steel Drawings

- Are Metal Buildings Cheaper Than Wood Buildings?

- Benefits of Metal Buildings For Agricultural Use

- Choosing the Right Location For Your Metal Building

- Making a Prefab Steel Church

- Passive Housing & Metal –Made for Each Other

- Uses for Metal Structures You May Not Have Known

- Why Do You Need a Prefabricated Home

- What Do You Need To Know Before Designing a Steel Structure Workshop?

- Why Should You Choose a Steel Frame Home Over a Wooden Frame Home

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.