Pre Engineered building manufacturer

pre engineered Metal building Manufacturer/ pre engineered steel building manufacturer / PEB structure / PEB steel Structure / pre engineered Heavy steel Building

Pre Engineered Building Manufacturer Trend

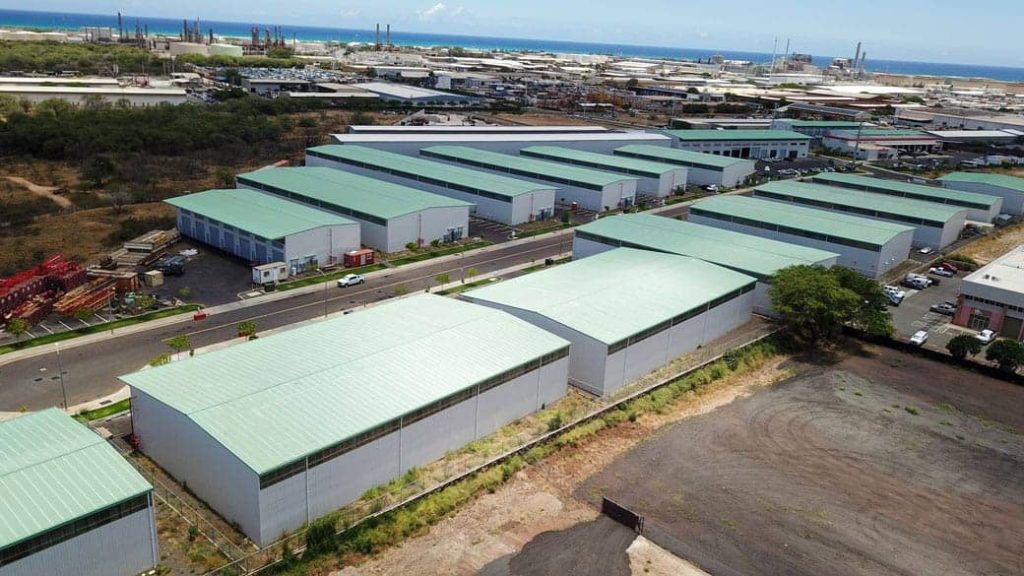

In recent years, the pre engineered building manufacturer construction industry has entered a period of rapid development, with an increasing number of projects all over the world and growing market demand. Due to its lightweight, efficient, and standardized characteristics, the pre engineered buildings have gradually become an ideal choice for modern architecture and have gradually taken over the construction industry.

Firstly, the construction speed of pre engineered building manufacturer is faster than other types of buildings anywhere else. In many cases, traditional buildings will face construction delays. However, pre engineered building manufacturer requires factories to produce many components in advance, ultimately reducing on-site construction time. Meanwhile, in the production process, it is necessary to strengthen the centralized and unified quality control of pre engineered buildings, to reduce the human factors caused by construction defects.

Secondly, unit design can be effectively used to build components and can be easily rearranged or reused in the future as it can be easily reassembled or reused. This also reflects the characteristics of sustainable development. At the same time, with the increase in labor costs, the economic benefits of pre engineered steel buildings begin to emerge. Although the initial investment is relatively high, it accelerates the construction period, and reduces labor costs, and the cost advantage is usually more obvious in the later maintenance costs.

Moreover, environmental protection and sustainable development are topics that cannot be ignored in the construction industry. The concept of green building is reflected in the material selection and construction process. Compared to traditional buildings, pre engineered building manufacturers can control more physical waste during the production process and use more recyclable and environmentally friendly materials to reduce their impact on the environment.

The flexibility of pre engineered building design is gradually being widely accepted. K-HOME can customize PEB designs based on specific customer requirements to give prefabricated buildings different functions. The usefulness of the model can be applied in all fields from industrial building, agricultural building, commercial building, and residential building, greatly improving the adaptability of building functions.

If you are looking for fast construction, low cost, and safe pre-engineered building, K-HOME is your best choice.

Pre Engineered Metal Building Supply

Pre engineered buildings are widely used for various purposes and fields, including industrial, commercial, agricultural, and residential facilities. You can contact us for exclusive designs and solutions.

Industrial buildings: steel structure factories, steel structure workshops, prefabricated warehouses,

Commercial buildings: steel structure storage facilities, super wholesale market, garage, indoor sports stadium, repair workshop, steel structure exhibition hall

Agricultural buildings: poultry farms, cattle farms, racecourses, granaries, barns

Residential buildings: worker dormitories, student dormitories, farm accommodations, office buildings

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted pre engineered building manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

List Of Pre Engineered Building Manufacturers

You can find a lot of pre engineered suppliers on the Internet. Here is a list of some of the more well-known pre engineered building manufacturers. In order to get better prices and designs, you can consult more experts.

ALLIED: Allied Buildings provides customers with a full range of steel structure building solutions through its global network, professional team and rich project experience. From creative design to efficient execution, Allied always focuses on customers and creates long-term value for customers. It is a provider of pre engineered building solutions, focusing on solving the most complex challenges and building a legacy for generations to come.

Butler: Butler Manufacturing has nearly 120 years experience of pre engineered building manufacturer, focusing on manufacturing prefabricated metal buildings, which are designed to be flexible, durable and easy to maintain to meet various construction needs. They emphasize their efforts in environmental protection and sustainable development, such as using recyclable materials, reducing energy consumption, etc., and providing first-class PEB structure building solutions for builders and building owners.

Nucor: With over three decades of experience, Nucor Building Systems provides fully customized pre engineered metal building solutions to meet customers’ unique building needs. With innovative roof insulation systems, the company is committed to providing innovative and sustainable PEB building solutions to meet future challenges.

PEMB: PEMB-USA is an expert in pre engineered building manufacturer, providing one-stop services from sales to manufacturing. Core services include sales, engineering design, drafting, and manufacturing, and they are committed to creating high-quality metal building projects for customers. Detailed evaluation of project details, providing quotes accurate to every bolt, and ensuring transparency. From project concept to completion, They always maintain close contact with customers and provide all-around support, which has won the trust and praise of many customers.

Armstrong: Armstrong Stee can provide steel building kits for various projects from basic to complex. Customers can lock in current steel prices by paying a small engineering fee. Building experts provide full guidance from the beginning to the end of the project to ensure that customers complete the project smoothly. Custom engineering and metal building design options are available to meet customers’ appearance and functional needs.

K-HOME: K-HOME is a pre engineered building manufacturer in China with thirty years of experience in prefabricated structure manufacturing. We provide cost-effective prefabricated building solutions for users around the world. We have scientific and fast calculation methods to provide you with multiple schemes for comparison. K-HOME’s pre engineered steel structure design provides unlimited possibilities for innovative production solutions, making it cost-effective. The cost-effectiveness and continuity of these structures make us one of the most popular pre engineered building manufacturers. We can customize these structures to meet various structural and aesthetic design requirements. In addition, K-HOME has a very large advantage in steel crane building structure solution. We can provide you with crane supporting pre engineered steel structure with the best quality.

Pre engineered building manufacturer

Pre engineered building manufacturer offer comprehensive solutions for the design, fabrication, and construction of pre-engineered buildings.

K-HOME is a global leader in pre engineered steel building design and pre-engineered steel building manufacturing, offering a wide range of products and services with efficient and cost-effective building solutions. We specialize in pre engineered metal building systems for a variety of applications.

Pre Engineered Building Manufacture Construction Steps

The typical installation process of pre engineered building manufacture can be divided into several main steps:

Site preparation: Site preparation is required before construction, including cleaning the construction area, surveying the land, and ensuring that the ground is level. In addition, the foundation position needs to be determined based on the design drawings.

Basic construction: Build the foundation according to the design drawings. Before pouring concrete, excavation and foundation treatment should be carried out to ensure that it can withstand the load of Pre Engineered Building manufacturing. After the foundation is completed, the concrete should be cured for 7 days before proceeding with the subsequent installation steps.

The first step after the foundation is completed is to transport the steel structure frame. When transporting, first separate the various components and transport them to the construction site, then connect them with bolts to form a rigid frame. When installing, first install the main column and main beam, and then install the secondary beam and auxiliary structure. The bolted or welded connections of steel frames usually ensure the stability of the system.

Installation of enclosure structure: After the steel structure installation is completed, install the walls and roof. The installation method varies depending on the selected enclosure material. Usually, the walls and roof panels are connected to the steel structure separately through embedded bolts or dowels. In most cases, connections are made through bolts or pins to form a complete whole.

Installation of doors, windows, and supporting facilities: After the installation of the enclosure structure is completed, install doors and windows. The selection of doors and windows should be based on the functional and aesthetic requirements of the building, and attention should be paid to the sealing of the installation to save energy. Next is the installation of electrical, plumbing, ventilation, and other systems.

Interior decoration: The acceptance and delivery of pre engineered building manufacturing should be strictly carried out following regulations. Interior decoration can be designed and selected according to specific usage requirements. Indoor decoration includes floor, ceiling, and wall decoration, as well as lighting, air conditioning installation, and other equipment. It can also include partitions and space division according to actual needs.

After completing all the above steps, the building can be accepted. Acceptance mainly includes structural safety, whether functional facilities are normal, fire safety, and inspection of aesthetics. Only after confirming that everything meets the standards and specifications can the building be delivered for use.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all pre-engineered steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.