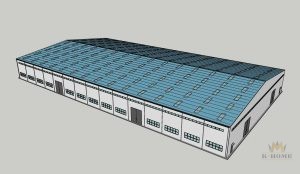

Steel Frame Workshop & prefabricated workshop

steel structure workshop / steel workshop building / insulated workshop buildings / steel workshop kits

With the development of modern industry, many business owners urgently need fast and cost-effective industrial workshop solutions. Traditional construction models often face challenges such as long construction periods and difficulty controlling costs. So, what construction method can effectively address these challenges? The answer is undoubtedly prefabricated steel structure workshops.

Steel frame workshops, with their superior comprehensive advantages, have become the mainstream choice for industrial construction. Especially for industrial scenarios with large spans and high loads, steel structure workshops demonstrate irreplaceable adaptability. This advanced prefabricated workshop system fundamentally addresses the shortcomings of traditional construction, providing clients with a faster, more economical, and more reliable steel workshop building solution.

What is a Prefabricated Steel Frame Workshop?

Steel frame workshops refer to a building system whose primary load-bearing components are constructed entirely of steel. This includes steel foundations, steel columns, steel beams, steel trusses, and steel roofs. Modern industrial plants widely utilize steel trusses due to their large span requirements. Enclosures can be constructed from lightweight materials or brick walls, achieving a balance between cost-effectiveness and practicality.

Steel’s inherent strength and durability, combined with its ability to withstand harsh environments, make it particularly suitable for industrial buildings. Prefabricated steel frame workshops go a step further, with core components prefabricated in-plant and then transported to the site for efficient assembly. This prefabrication model not only inherits the inherent advantages of steel structures—lightweight, large spans, and excellent seismic resistance—but also significantly improves construction speed and quality control.

For this reason, prefabricated steel workshops have become the preferred building type in industries such as manufacturing, warehousing, and logistics, and large distribution centers. This steel building system provides business owners with a fast, reliable, and cost-effective Steel Workshop Building solution.

buy direct from the manufacturer | k-hOME

Before selecting a prefabricated steel frame workshop manufacturer, it’s important to thoroughly research and consider factors such as the company’s reputation, experience, the quality of materials used, customization options, and customer reviews. Additionally, obtaining quotes and consulting with representatives from these companies can help you make an informed decision based on your specific project requirements.

K-HOME offers prefabricated steel buildings for various applications. We provide design flexibility and customization.

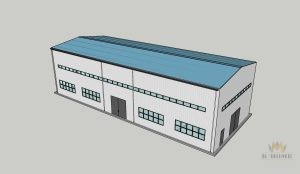

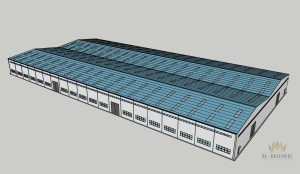

prefabricated steel frame building form | portal steel frame

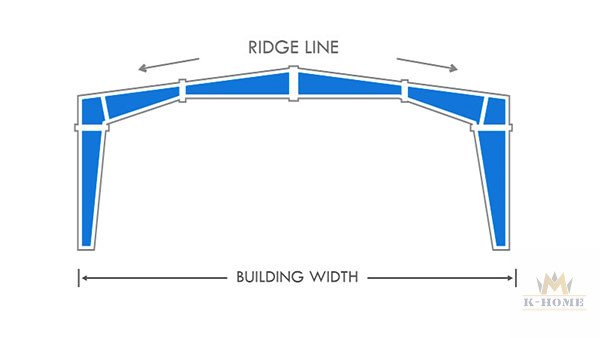

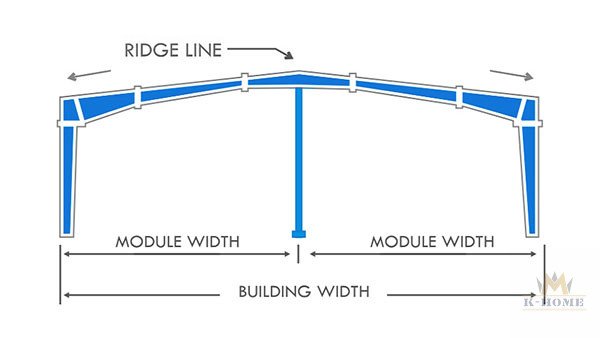

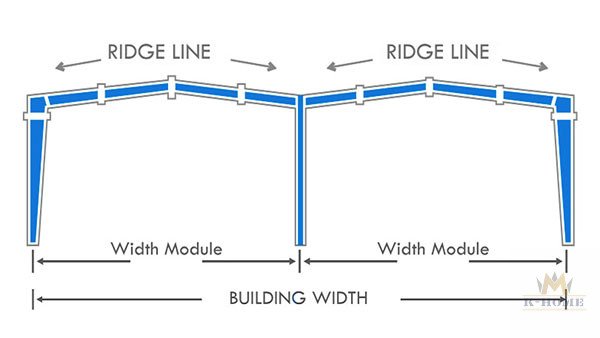

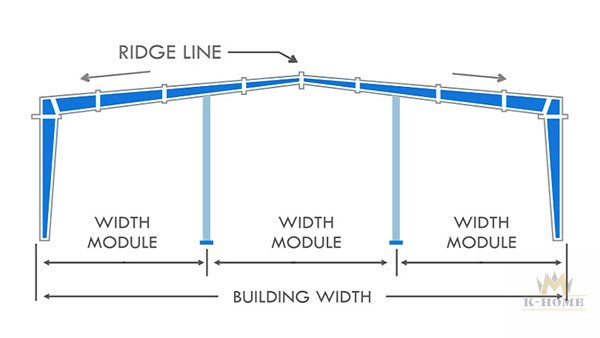

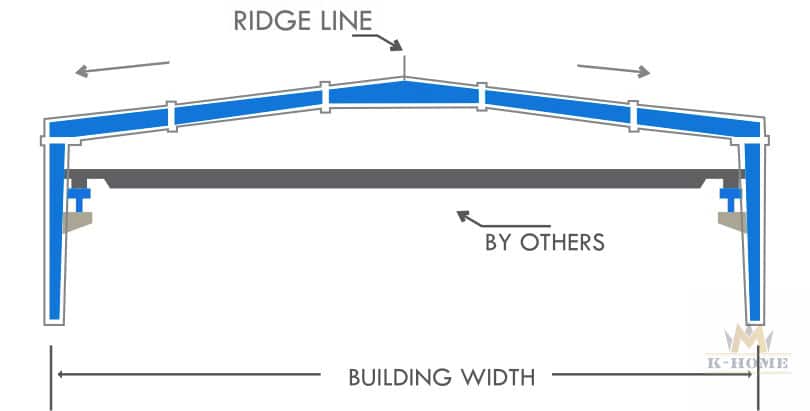

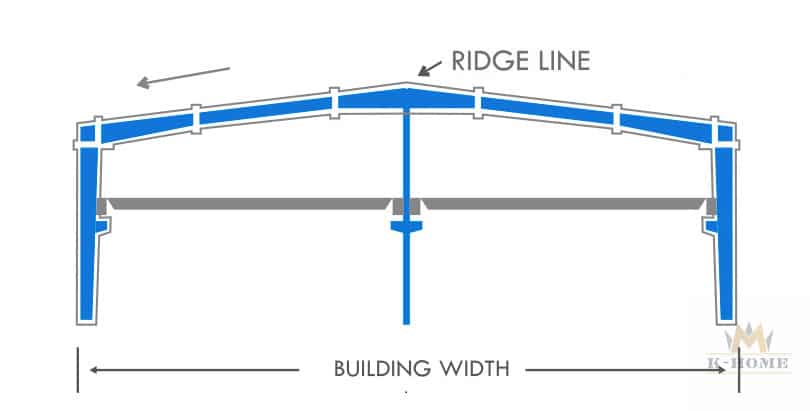

The portal steel frame system is one of our most mature solutions. Also known as a clear span steel structure, the steel portal frame is designed for single-story buildings requiring large open spans, making it particularly well-suited for applications such as warehousing, logistics, and industrial plants.

The load-bearing structure of our portal frame utilizes a variable-section or uniform-section solid-web frame, while the enclosure system utilizes a single-story steel structure with a lightweight steel roof and lightweight exterior walls. The entire steel frame structure consists of a load-bearing skeleton, purlins, wall beams, supports, walls, roof, and an insulation core. It features simple load-bearing, clear force transmission paths, rapid component fabrication, ease of factory processing, and a short construction period.

Portal steel frame workshop type

clear-span double-sloped double-span double-sloped multi-span mult-sloped multi-span double-sloped clear-span with overhead crane double-span with overhead crane

Key Components of Prefabricated Steel workshop Buildings

Prefabricated steel building mainly combined by 5 parts: Steel Structure, roof system, wall system, window and door, and accessories. Let’s introduce them one by one in detail.

Steel Structure

Main steel mainly includes beam and column, the steel column is Hot roll H-section Q345 material, it includes corner column, the steel column quantity is changeable, it was calculated according to the area, the local environment, the standard distance also call interior bay are 6m.

Angle Channel-C H-Beam I-Beam Steel Columns Tie rods Purlins Cross bracings

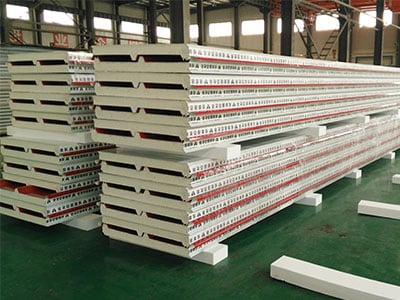

Roof System

The roof system mainly has following parts:

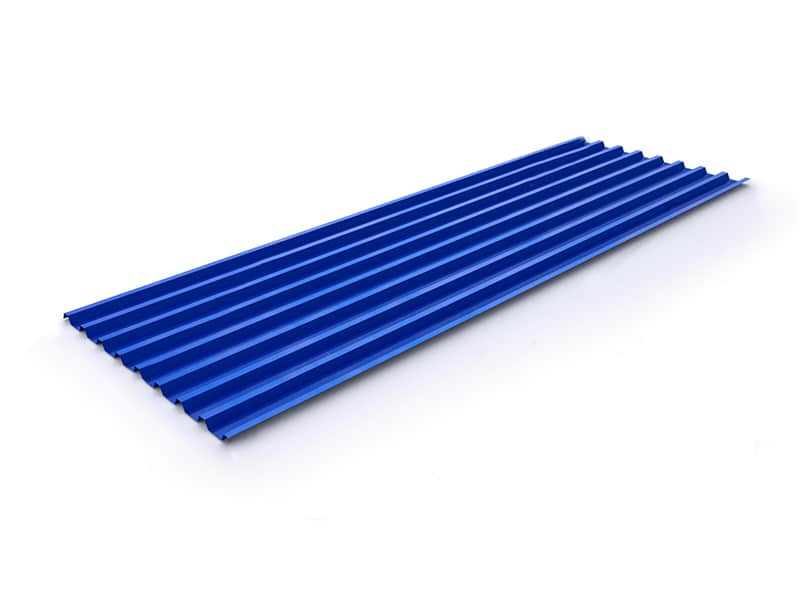

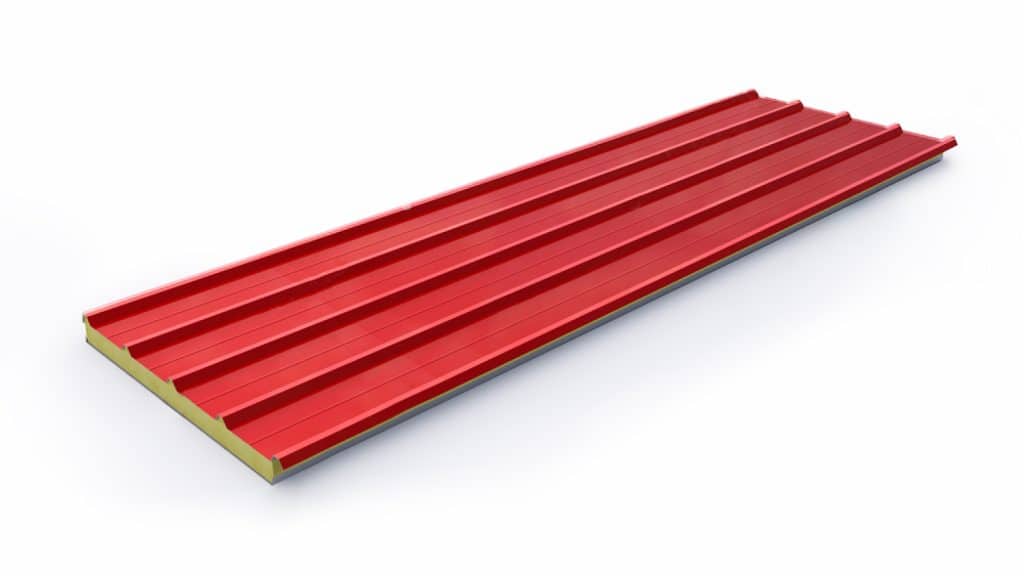

- roof panel/Single steel board, this mainly based on the local temperature.

- Ventilator: it also has turbo and ridged ventilator 2 kinds.

- Sky light: this is mainly used to give more light.

- Water gutter: this is optional, the water gutter are popular used in rainy weather.

Wall System

Wall panel/single steel plate: it is the same with the roof system.

Windows and doors

We have 100 types of windows and doors. You can choose from our catalog, or we can help you design a special one.

Accessories

Beside the main part in important, we also pay attention to the accessories, such as crews, bolts, and glue, these consideration will make the building modern and sleek.

Top 5 Advantages of Choosing a Steel Structure Workshop

Steel structure workshops offer numerous advantages, which is why more and more business owners are choosing prefabricated steel buildings. This building system is an excellent choice for businesses seeking maximum functionality and cost-effectiveness.

- Durability: The greatest advantage of steel structure workshops is their durability. Steel’s inherent high strength enables steel structure workshops to easily withstand extreme weather, heavy loads, and frequent use. They offer excellent earthquake and wind resistance, and their fire resistance rating can be enhanced with the use of fire-retardant coatings. This inherent strength ensures the building’s long-term durability and operational safety.

- Affordability and Cost Control: While the initial investment in a steel structure workshop may be slightly higher than that of traditional buildings, it is a more economical option over its entire lifecycle. First, prefabrication reduces material waste. Second, steel structure construction takes a shorter time, reducing labor costs. Finally, compared to traditional buildings, steel structure workshops require virtually no maintenance, minimizing ongoing maintenance costs.

- Flexible Layout: Steel frame workshops can be manufactured to your desired size and offer flexible designs. Widths up to 30 meters can be designed as open, column-free, barrier-free spaces, perfectly adapting to changing production line and layout requirements.

- Short Construction Period: Prefabricated steel workshop components are precisely manufactured in the factory, with only efficient on-site assembly required. This significantly shortens the construction period. This means your Steel Workshop Building project can be put into production sooner, accelerating return on investment and significantly reducing the risk of delays due to factors such as weather.

- Sustainability: Steel structure buildings are recognized as an environmentally friendly choice. Steel is 100% recyclable, prefabrication produces minimal construction waste, and energy consumption is significantly lower than concrete buildings.

How to design a steel frame workshop? | k-hOME’s design process

As a professional PEB building manufacturer, K-HOME maintains a comprehensive and scientific design and delivery process to ensure the safety, quality, and timely completion of each project. Our designs are manufactured in strict compliance with China’s GB standards and are also adaptable to international standards.

For overseas projects, our engineering team is proficient in international standards such as American Standards (ASTM) and European Standards (EN). They will conduct professional structural review and calculations based on the standards of the project location to ensure full compliance with local building regulations.

Requirements Confirmation and Preliminary Design:we will conduct an in-depth consultation with you to gain a detailed understanding of your project requirements and building environmental conditions. For example, we will consider natural factors such as wind, rainfall, snowfall, and earthquake intensity. This critical data will be directly incorporated into our steel structure design to ensure the building’s safety and reliability. Based on this information, our design team will initiate structural calculations and preliminary design, selecting the appropriate steel material type, structural form, and component dimensions. We will also conduct rigorous load analysis in accordance with international standards to ensure structural stability and safety.

Design Review and Quotation: Once the design is completed, we will enter a professional review phase, where experienced engineers will thoroughly verify the calculations and construction drawings to ensure compliance with regulations and construction requirements. Upon approval, we will provide you with a clear and transparent steel structure quotation, covering all costs including production, packaging, and shipping, to help you accurately manage your project budget.

Prefabrication: Once the quotation is confirmed, prefabrication begins. All steel components are meticulously manufactured in our factory, and we prepare complete technical documentation and construction drawings to ensure machining accuracy. Upon completion, the product is standardized and packaged, ready for shipment.

Ocean Freight: K-HOME will coordinate container loading and international logistics throughout the entire process, monitor shipping progress in real time, and maintain close communication with you to ensure the safe and timely delivery of your goods. Upon arrival at the port, you simply complete customs clearance and pick up your goods according to local regulations, ensuring a streamlined and efficient process.

Technical Support: To assist with on-site installation, we not only provide detailed installation videos and drawings, but can also dispatch engineers to provide on-site technical guidance upon request, ensuring a worry-free installation.

In short, K-HOME pays attention to every detail—from preliminary design and structural calculations to prefabrication, logistics tracking, and after-sales support. We are committed to providing customers with comprehensive steel structure solutions to create safe, durable, and high-value industrial buildings.

Most Popular steel frame workshop kits design plans

cost breakdown of steel frame workshop

Price is one of the most important considerations for every business owner when planning a project. It’s important to note that the price of steel structure projects is not fixed. Due to its diversity and complexity, costs are affected by a combination of variables. As a professional steel structure building contractor, K-HOME is committed to providing clients with safe, reliable, and cost-effective steel structure solutions, ensuring that every quote is reasonable and transparent.

The main factors affecting the cost of steel structure projects include:

- Project scale and complexity: The project’s size, structural form, and technical difficulty directly impact resource investment. Larger and more complex structures require more materials, manpower, and construction time, significantly impacting the overall cost.

- Material selection: Steel type, connectors, maintenance systems, and the grade and brand of anti-corrosion coatings are significant components of the cost. K-HOME assists clients in selecting the most cost-effective material solution while ensuring structural safety.

- Construction time: Projects with tight deadlines may require accelerated prefabrication, additional teams, or parallel operations, all of which incur additional resource coordination and management costs. 4. Project Location: Regional labor costs, logistics costs, and on-site environmental conditions (such as wind and rain, and seismic requirements) will also impact the final price.

K-HOME, with its professional design and construction team, provides integrated steel structure engineering services, from pre-planning, structural design, prefabrication, on-site installation, to ongoing maintenance. Through scientific management and efficient execution, we strive to deliver high-quality, long-lasting steel structures to our clients while controlling costs.

Common Applications for Prefabricated Workshops

The adaptability of steel frame workshops offers efficient construction solutions for projects of varying sizes. Its applications span a wide range of scenarios, encompassing manufacturing plants, production workshops, warehouses, and logistics centers. Steel structures can address virtually any industrial or commercial application requiring spacious, sturdy, and accessible space. This building system offers high flexibility, allowing for customized designs tailored to a company’s specific needs. The following are typical applications for steel workshop buildings:

Manufacturing Plants and Production Workshops

Steel frame workshops provide a sturdy, durable, and safe production environment for all types of manufacturing companies. Their flexible space allows for seamless integration of crane systems, heavy equipment, and production line layouts, meeting the stringent structural and load-bearing requirements of high-end manufacturing.

Warehousing and Logistics Centers

Steel workshop buildings are an ideal choice for modern warehousing solutions. Their excellent durability and fire resistance effectively safeguard goods and materials. Furthermore, they are easily expandable, allowing for vertical or horizontal expansion as warehouse capacity grows, adapting to the ever-changing needs of the logistics industry.

Commercial and Sports Facilities

In recent years, more and more commercial projects have chosen to transform steel-structured factory buildings into large public spaces, such as indoor basketball courts, badminton halls, and multi-sports centers. Their spacious interiors and rapid construction schedule make them particularly suitable for commercial venues with large spans and column-free designs.

why K-HOME Steel building?

As a professional PEB manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.