Prefab Steel Warehouse for automotive spare parts storage in Tanzania

The demand for reliable, efficient, and climate-adaptive industrial facilities has made the Prefab Steel Warehouse in Tanzania an increasingly popular choice for investors and businesses.

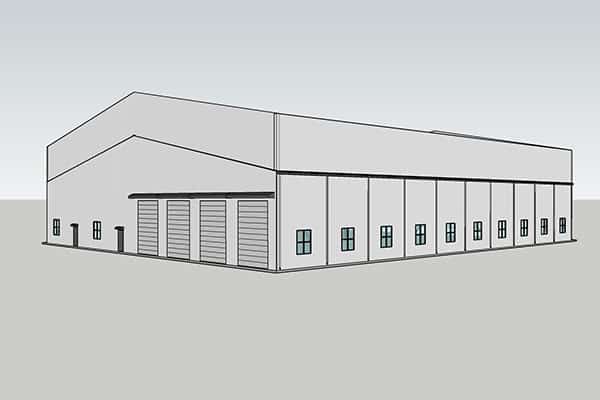

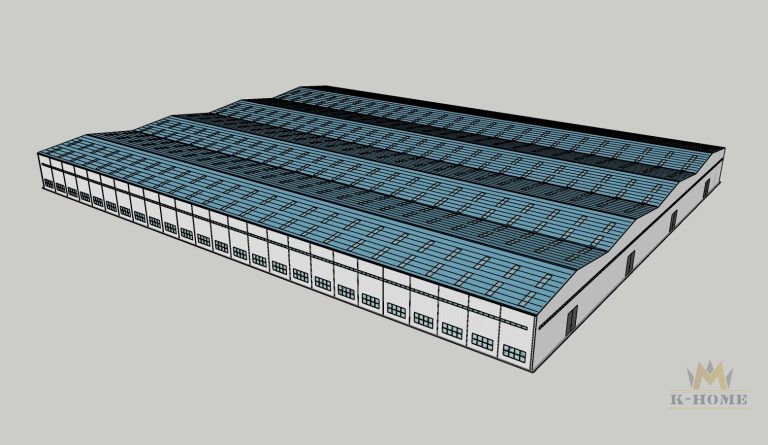

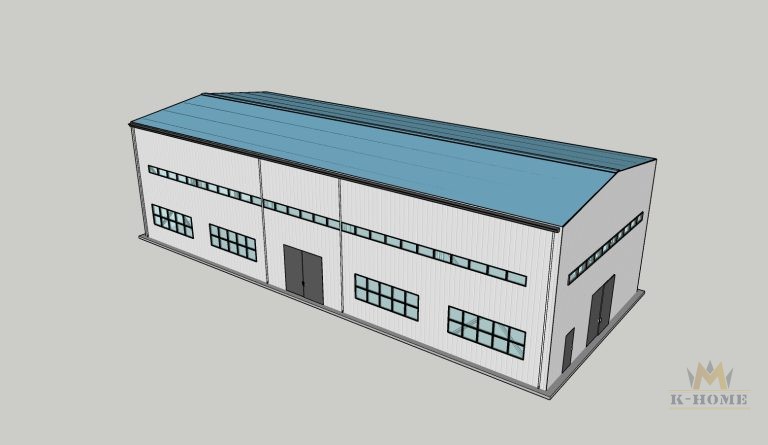

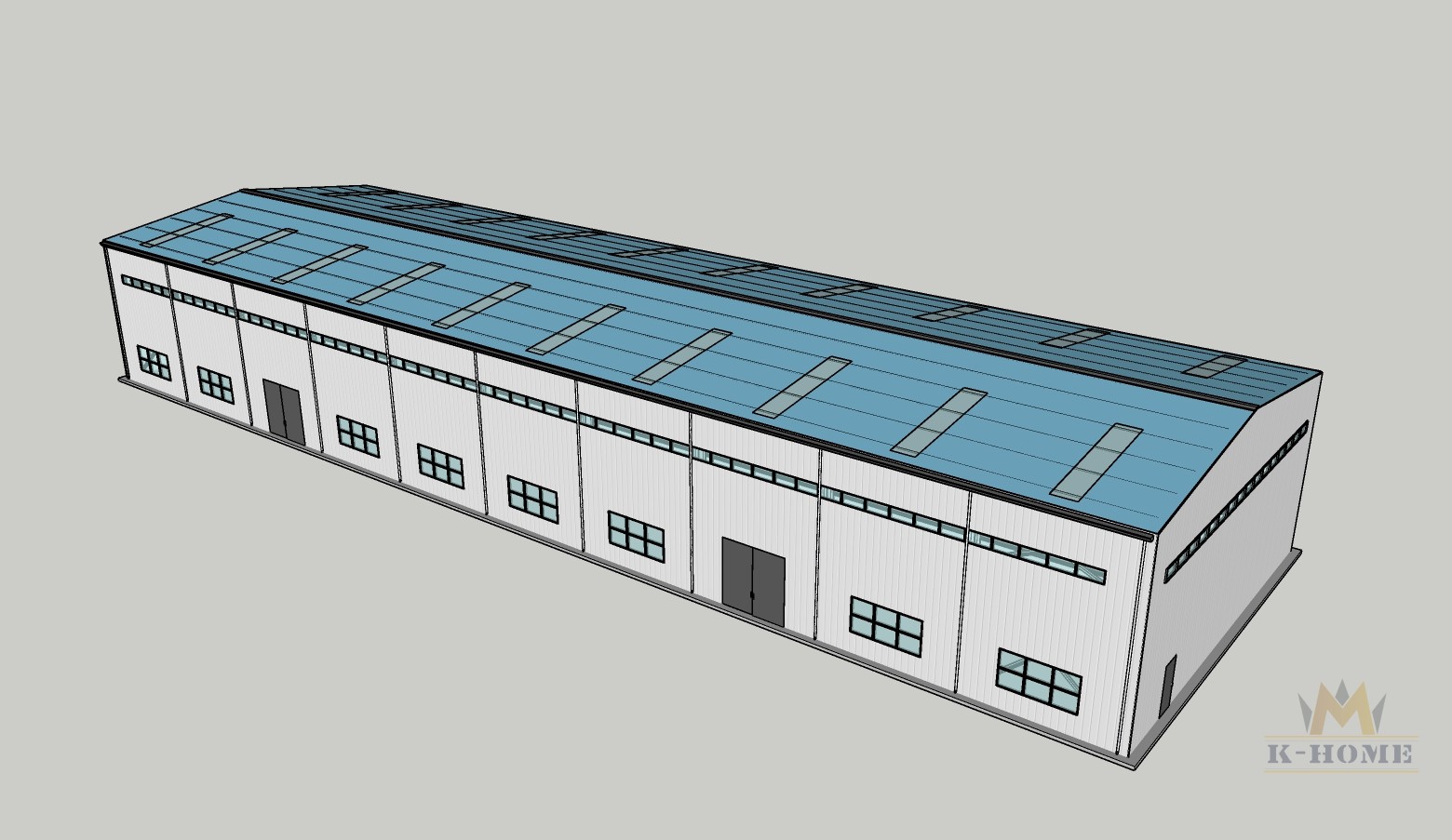

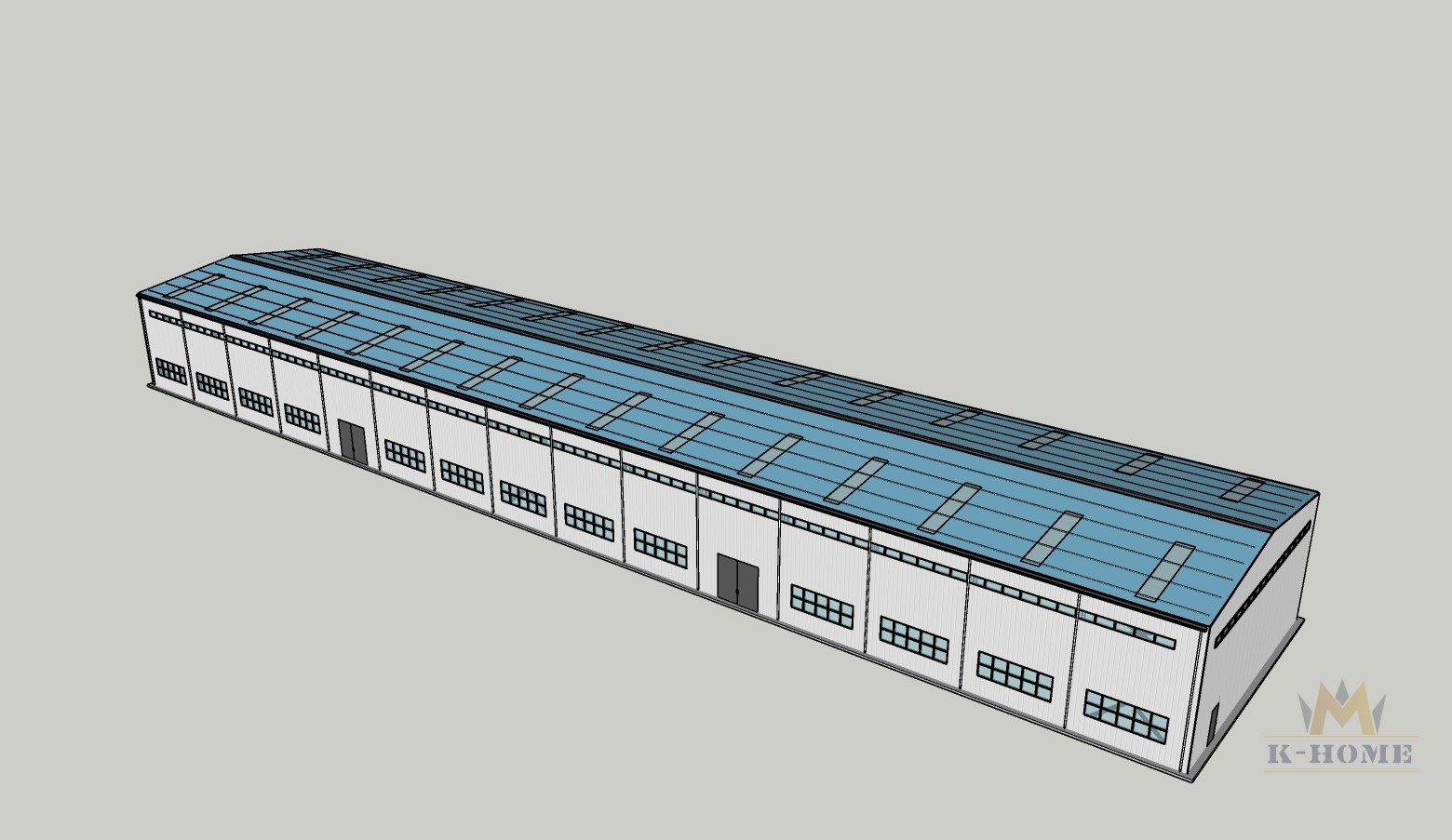

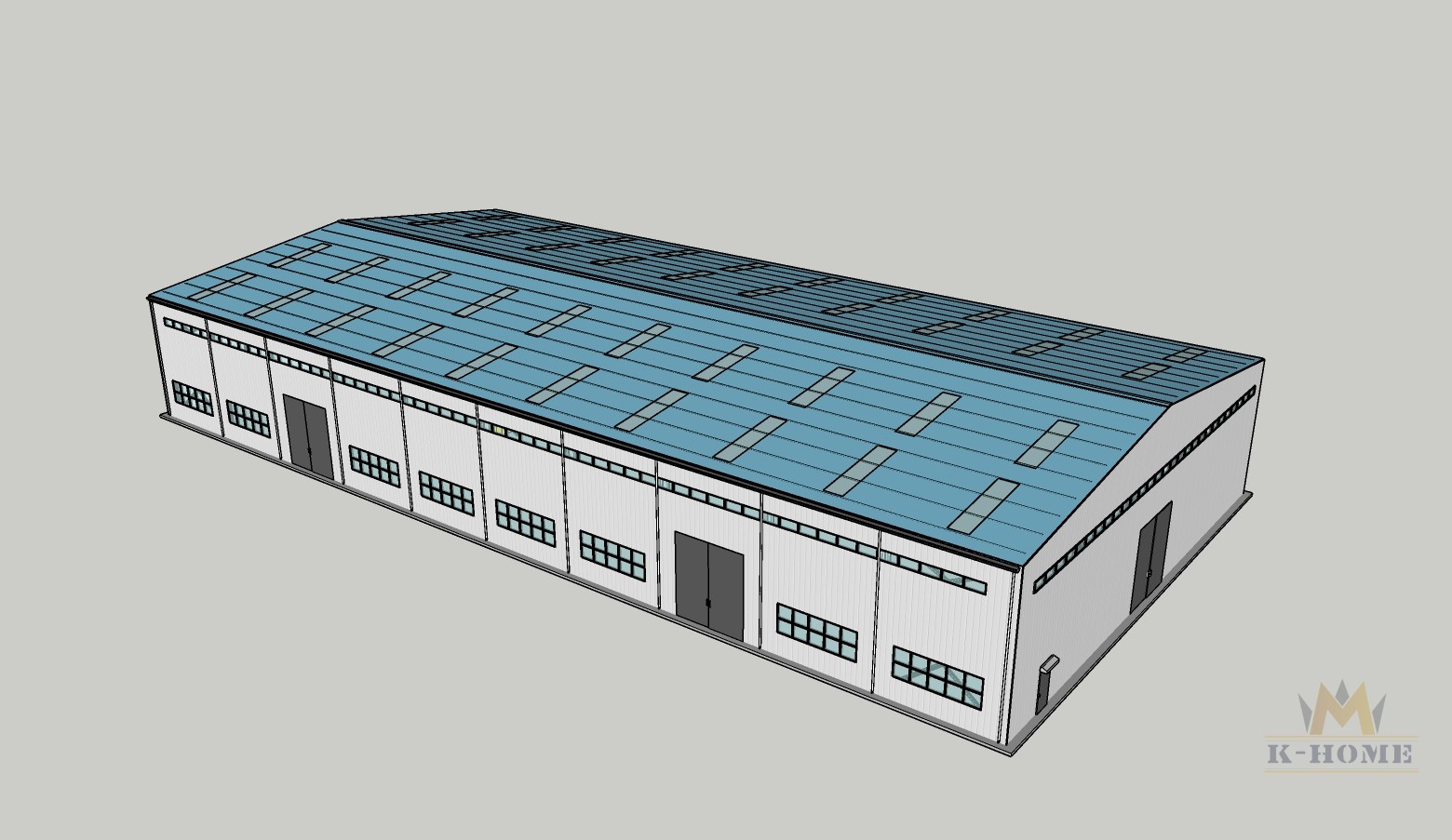

In this project, a warehouse with a span of 40m, length of 50m, and height of 8m was designed specifically for automotive spare parts storage. Without the need for heavy lifting equipment, this warehouse demonstrates how prefabricated steel structures can provide long-term value in Tanzania’s diverse climate conditions.

Project Overview: Warehouse for Automotive Spare Parts

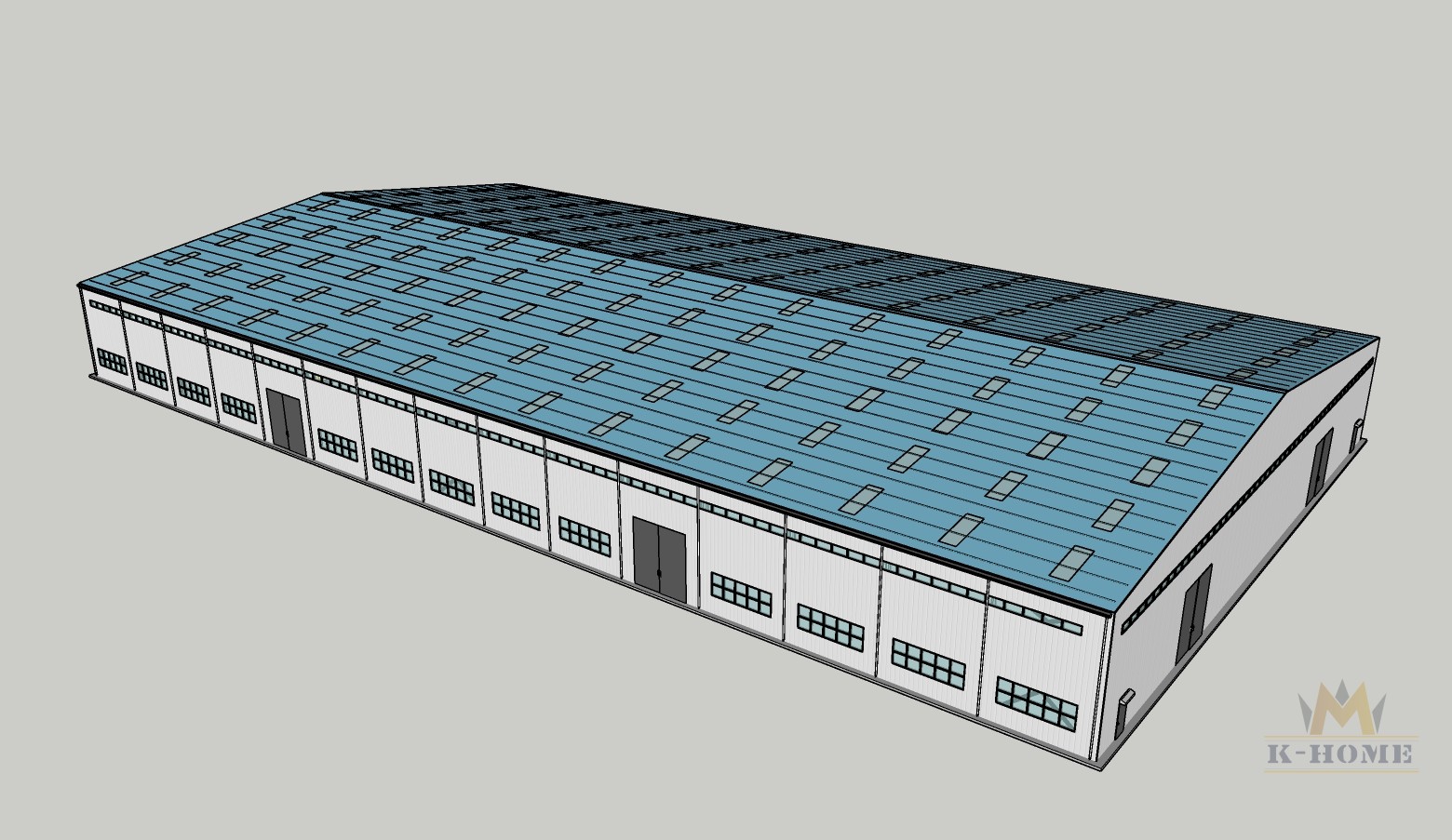

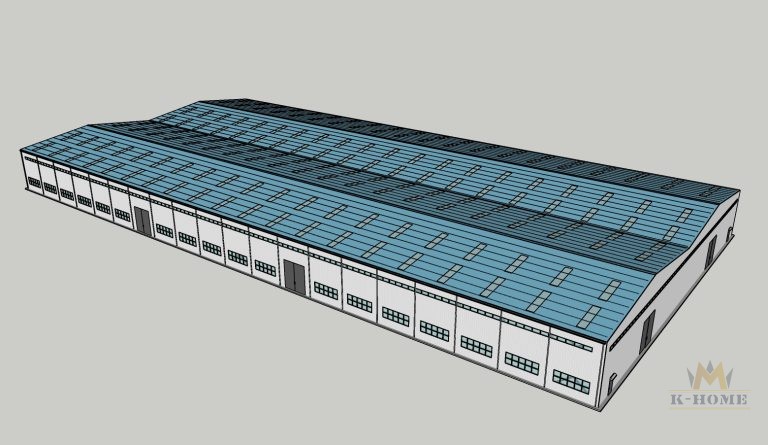

The recent Prefab Steel Warehouse in Tanzania was designed to support the growing automotive industry by offering a durable and spacious storage facility for spare parts. With a clear span of 40 meters, the structure provides ample space for storage and operations. Its 50-meter length and 8-meter height ensure the interior can accommodate large inventories without crowding.

Since the project does not require cranes or heavy-duty lifting systems, the design emphasizes cost efficiency while still maintaining strength and safety. This project showcases how prefabricated steel solutions are ideal for industrial applications in Tanzania.

Steel warehouse design based on the Tanzanian climate:solutions for durability and Safety

Designing a Prefab Steel Warehouse in Tanzania requires special attention to the country’s climate, which varies from coastal humidity to highland rainfall.

Key Environmental Challenges

In designing a Prefab Steel Warehouse in Tanzania, it is essential to consider the country’s diverse environmental conditions. Coastal regions such as Dar es Salaam experience year-round humidity and heat, which can accelerate corrosion if not properly addressed. In the highlands, heavy seasonal rainfall requires strong roofing and effective drainage systems to ensure durability. Additionally, certain areas are prone to strong winds and occasional seismic activity, making structural stability a critical factor in the overall design.

Design Adaptations for Local Conditions

To address these environmental challenges, K-HOME customized the structural design of the Prefab Steel Warehouse in Tanzania with several key features. All steel members are treated with anti-corrosion coatings to prevent rust, while wind-resistant frameworks are engineered to comply with local wind speed requirements.

Thermal expansion is carefully considered to maintain stability under fluctuating temperatures, and efficient roofing combined with advanced drainage systems ensures the building can withstand heavy seasonal rainfall.

These design elements ensure the Prefab Steel Warehouse in Tanzania remains safe, durable, and operational for decades.

Structural System and Materials

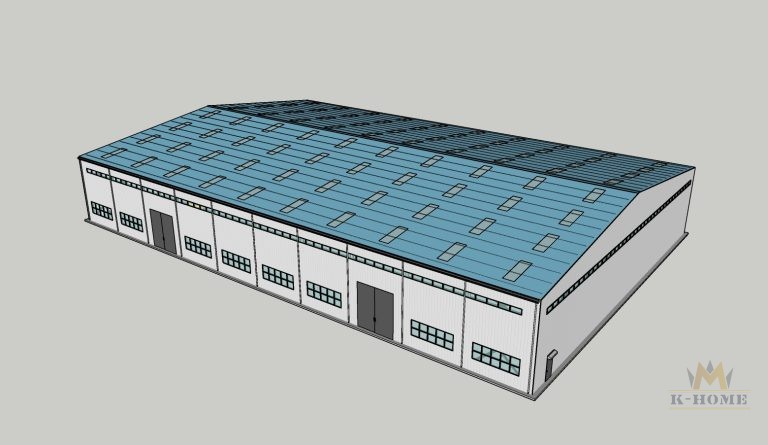

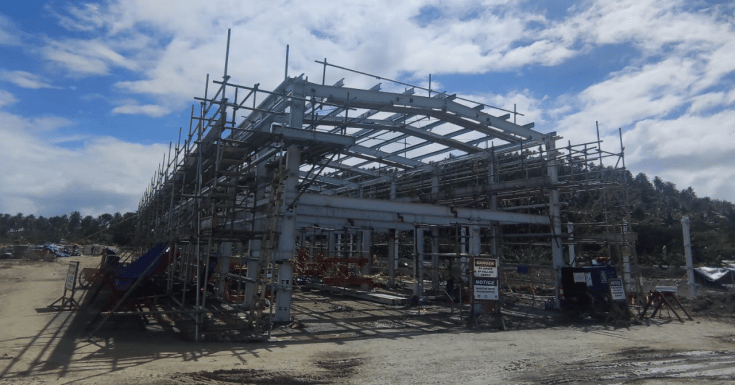

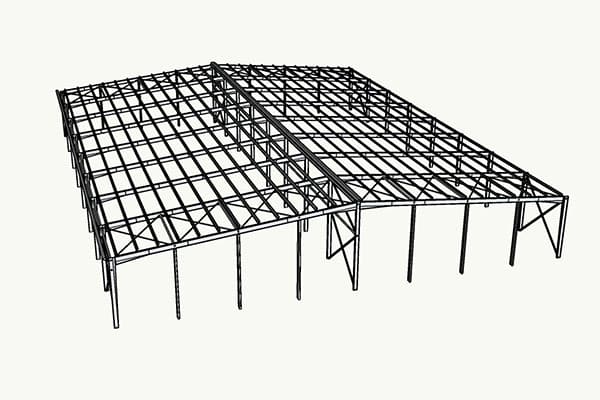

The structural system of the auto parts warehouse is designed based on rigorous mechanical calculations and comprehensive structural audits, aiming to provide high-strength support for the building and ensure its stability and safety in long-term use.

main and secondary steel frame structure

The project’s primary steel frame (including columns and beams) is constructed of Q355B steel, weighing 37.9 tons. The surface is shot-blasted to Sa2.5 and coated with alkyd paint to ensure the core’s strength and durability. The secondary structure (including purlins, braces, and tie rods) is also constructed of Q355B, weighing approximately 25 tons and hot-dip galvanized, providing excellent support and corrosion resistance for the entire building.

Enclosure system

The building envelope utilizes 0.5mm thick colored steel plates, combining lightweight, high strength, exceptional durability, and low maintenance. The roof system incorporates a built-in glass wool insulation layer, effectively blocking heat transfer from the outside and providing stable and suitable storage conditions.

Foundation

The reinforced concrete foundation provides a stable anchor for the entire warehouse structure, fully adapting to local geological conditions and building load requirements. It should be noted that all steel structure foundations are individually designed based on the specific soil parameters of the project site and overall load calculations to ensure long-term safety and stability.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

KHOME is a leading provider of steel structure solutions, delivering customized prefabricated buildings worldwide.

KHOME stands out in delivering Prefab Steel Warehouse in Tanzania projects thanks to its comprehensive advantages. Each project is supported by tailored engineering, ensuring the design matches local environmental and soil conditions.

Through advanced manufacturing, automated processes guarantee precision in cutting, welding, and surface treatment, resulting in higher durability. The company also provides fast delivery and installation, with pre-labeled parts that simplify logistics and shorten assembly time. At the same time, KHOME emphasizes sustainable construction, using recyclable steel and minimizing waste through prefabrication. With proven expertise and years of successful projects across Africa, KHOME has built a strong reputation for reliability and quality.

Partnering with KHOME means benefiting from shorter construction times (30–50% faster than concrete) and long-term operational savings.

You can send me a WhatsApp message (+86-18790630368), or send an e-mail (sales@khomechina.com) to leave your contact information. We will contact you as soon as possible.

KHOME’s Design and Construction Workflow

KHOME follows a systematic approach to ensure each Prefab Steel Warehouse in Tanzania meets international standards.

Our process begins with a consultation to understand client needs, usage, and environmental conditions, followed by customized design where engineering solutions are tailored to local wind speeds, rainfall, and temperature.

Manufacturing then takes place through automated steel fabrication to ensure accuracy and durability. In the logistics stage, components are shipped with clear documentation for easy on-site assembly, and finally, installation support is provided with 3D guides, manuals, and optional technical assistance. This integrated approach ensures smooth project delivery and client satisfaction.

Price of Prefab Steel Warehouse in Tanzania

The cost of a Prefab Steel Warehouse in Tanzania is USD 50 per square meter for this project. However, several factors can influence the overall price.

The cost of a Prefab Steel Warehouse in Tanzania is influenced by multiple factors. Larger spans and taller buildings naturally require more steel, while material specifications such as higher-grade steel, additional insulation, or anti-corrosion coatings can increase overall expenses.

Functionality also plays a role, as warehouses equipped with cranes, HVAC systems, or other specialized equipment demand reinforced designs. Moreover, climate adaptations like waterproofing, ventilation, and thermal insulation add to the construction cost. Finally, logistics—including transportation distance, port access, and local site conditions—significantly affect the final pricing.

Despite these variables, prefabricated steel buildings remain 20–30% more cost-effective than traditional concrete structures in Tanzania, especially considering reduced maintenance costs.

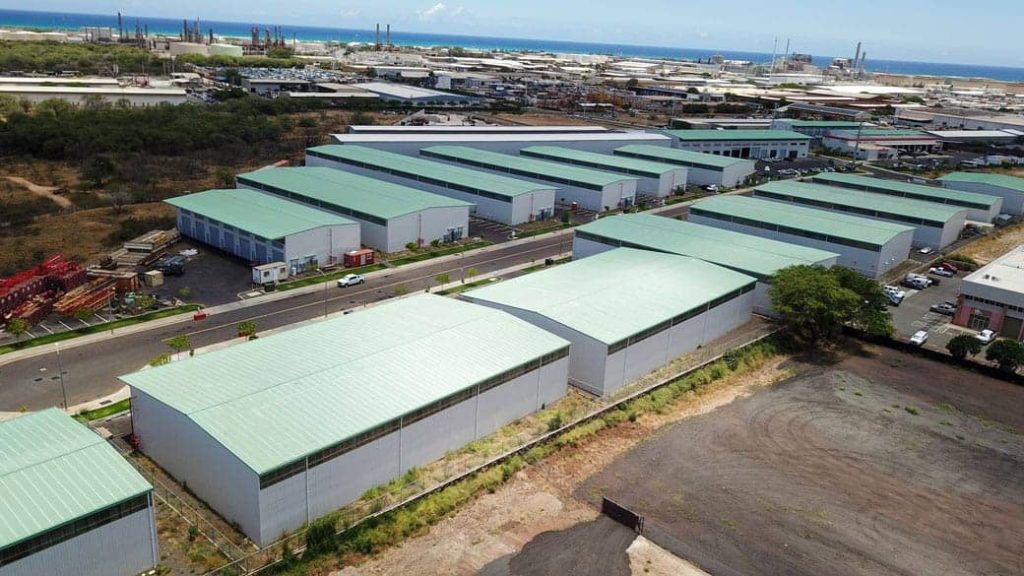

Applications Beyond Automotive Storage

While this project focused on automotive spare parts, the Prefab Steel Warehouse in Tanzania model can be applied across various sectors.

The applications of a Prefab Steel Warehouse in Tanzania extend far beyond automotive storage, making it a versatile solution across industries. In warehousing and logistics, these structures provide reliable facilities for goods ranging from machinery to agricultural products.

For manufacturing plants, the designs are adaptable with or without crane systems, depending on operational needs. In the agriculture sector, prefabricated warehouses offer hygienic, easy-to-maintain environments for crops and livestock. They are also well-suited for commercial use, where open-plan layouts support offices, retail operations, and other business functions.

The adaptability of prefabricated steel makes it the most versatile solution for Tanzanian businesses.

popular steel building kits sizes

120×150 Steel Building (18000m²)

Related project

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.