What is a Steel Structure?

A Steel Structure is a building system where steel is the primary load-bearing material. It enables rapid construction through prefabrication and on-site assembly. These prefab steel structures typically use high-strength steel, like hot-rolled or cold-formed sections, which offer excellent tensile strength and durability. This allows them to withstand natural disasters such as strong winds and earthquakes.

Their modular design is one of their main advantages. Construction time is greatly reduced since parts are prefabricated in factories and then delivered to the construction site for assembly. In addition to commercial and industrial structures, this technique is increasingly being applied in public and residential spaces.

| Component Structure | Material | Technical Parameters |

|---|---|---|

| Main Steel Structure | GJ / Q355B Steel | H-beam, Customized height according to building requirements |

| Secondary Steel Structure | Q235B; Paint or Hot Dip Gavalnized | H-beam, Spans range from 10 to 50 meters, depending on design |

| Roof System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to design |

| Wall System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to wall area |

| Window & Door | Color steel sliding door / electric rolling door Sliding Window | Door and window sizes are customized according to design |

| Fireproof Layer | Fire retardant coatings | Coating thickness (1-3mm) depends on the fire rating requirements |

| Drainage System | Color Steel &PVC | Downspout: Φ110 PVC Pipe Water Gutter: Color Steel 250x160x0.6mm |

| Installation Bolt | Q235B Anchor Bolt | M30x1200 / M24x900 |

| Installation Bolt | High-Strength Bolt | 10.9M20*75 |

| Installation Bolt | Common Bolt | 4.8M20x55 / 4.8M12x35 |

Types of Steel Structure Buildings

Portal Frame Steel Structure

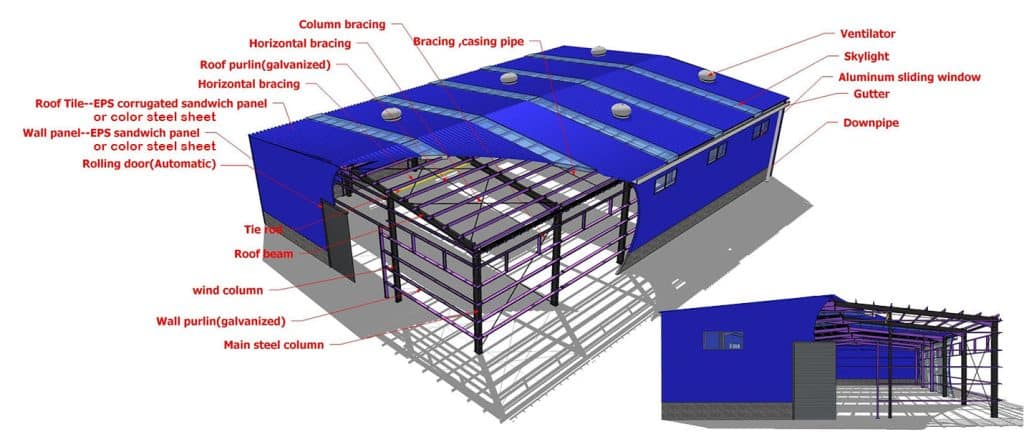

A portal frame steel structure is a traditional structural system. It consists of inclined rafters, columns, bracings, purlins, and tie bars. Its mechanical principle relies on a transverse rigid frame made of beams and columns. This frame resists wind and gravity loads through bending, with a clear load transfer path.

These steel structure buildings often use tapered H-shaped steel sections to optimize material use and reduce weight. They are known for being lightweight, fast to construct, and efficient. The building envelope is often constructed of corrugated metal sheets or color-coated steel sheets, combined with cold-formed thin-walled steel purlins, creating an energy-efficient and environmentally friendly building system.

Gabled frames are widely used in industrial plants, warehouses, gymnasiums, and supermarkets – buildings that require large spans.

Frame Structure

This is one of the most common steel structure types. It forms a stable load-bearing system through rigid connections between beams and columns. It is widely used in high-rise buildings, industrial plants, and commercial centers because it allows for large, flexible spaces.

Frame structures also offer good seismic performance. Steel’s high modulus of elasticity helps absorb earthquake energy, reducing structural damage. In practice, they are often combined with materials like concrete or glass to enhance aesthetics and functionality.

In summary, frame structures are an economical and practical choice, especially for projects requiring fast delivery and flexible design.

Space Frame Steel Structure

This is a three-dimensional grid system, typically used for long-span buildings like stadiums, exhibition halls, and airport terminals. It forms a stable spatial system through members and nodes, covering large areas without intermediate support columns.

The advantage lies in its light weight and high strength. It uses relatively less steel but can carry heavy loads. This structural type also offers great design freedom, enabling unique architectural shapes and visual impact.

Construction requires precise calculation and assembly, often relying on specialized software and teamwork. With advancing technology, space frames play a key role in sustainable building by reducing material waste and extending service life.

Overall, space frame structures are an ideal solution for long-span needs, showcasing modern engineering innovation.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted steel structure manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

Construction of Steel Structures

Design, prefabrication, transportation, and on-site assembly are all steps in the building process. Careful preparation is necessary for each step to ensure efficiency and quality.

design

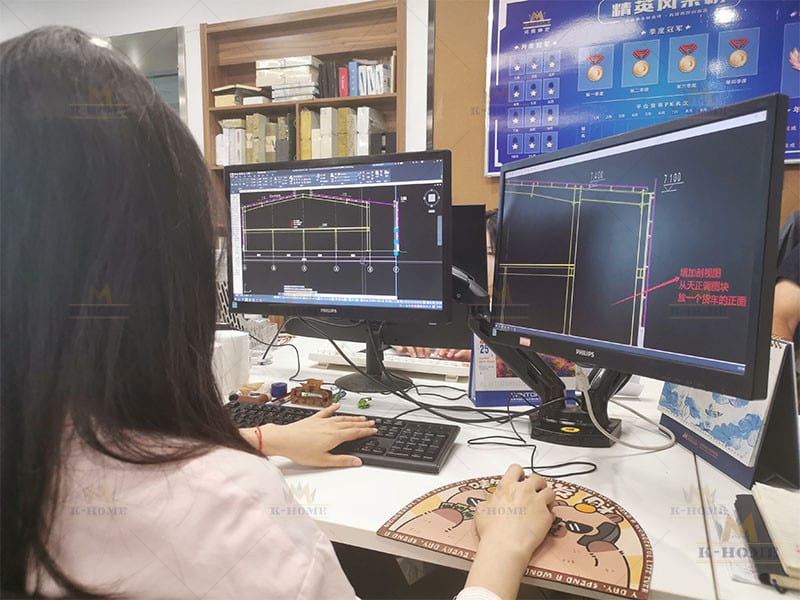

K-HOME designs the steel structure based on the client’s requirements, determining loads, dimensions, and material specifications.

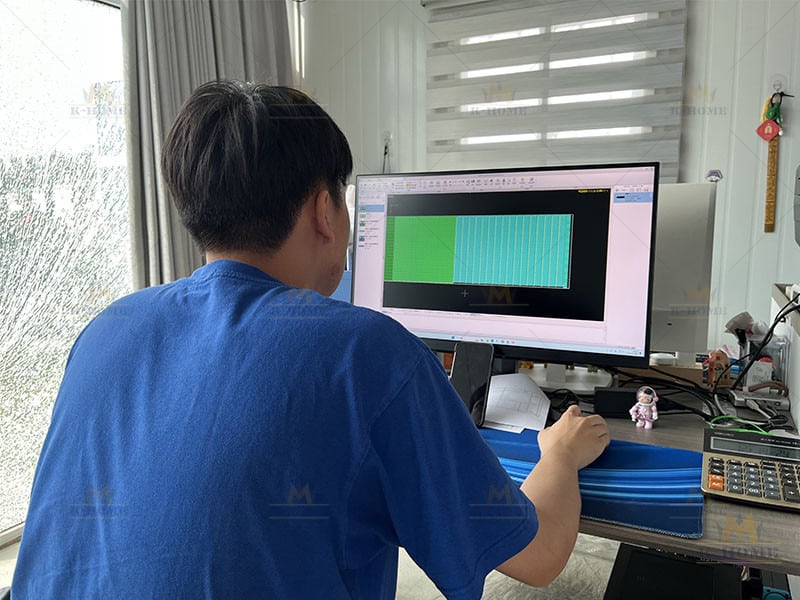

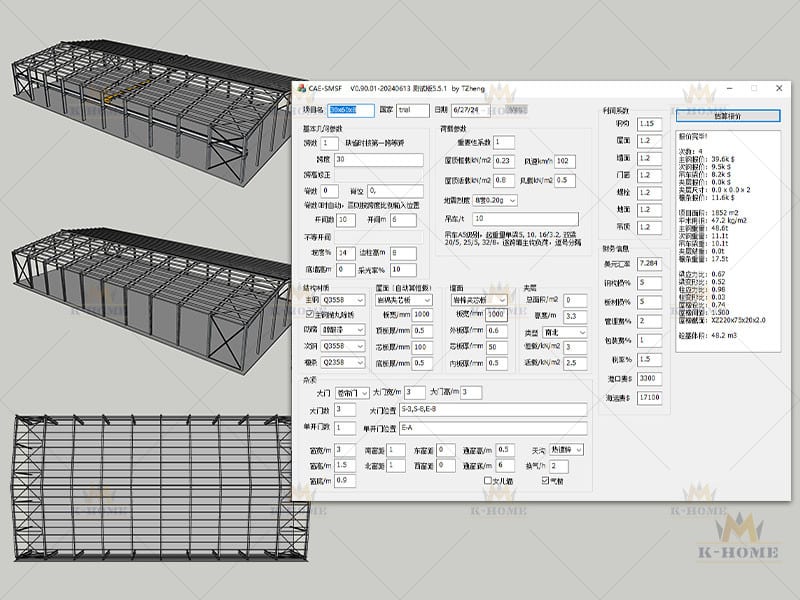

Design software is also a crucial component of steel structure design. KHOME has independently developed professional steel structure calculation software. This software quickly generates design drawings and quotes based on specific client requirements. Our software integrates advanced algorithms for automated structural analysis and optimization, ensuring economical and safe steel structure designs.

Using KHOME software, we can quickly produce detailed plans, including bills of materials and cost estimates, based on essential client parameters such as building dimensions, load requirements, and environmental conditions.

Most importantly, our team of professional structural engineers reviews each design to ensure that steel structure projects comply with relevant standards. This proprietary software not only enables KHOME to provide clients with customized steel structure solutions to meet diverse challenges, but also significantly shortens project preparation time, ensuring a prompt response to client needs.

manufacture

All components of the steel structure, such as beams, columns, and connectors, are prefabricated in the factory. This process utilizes automated equipment to ensure the precision of each component. The finished structure undergoes rigorous quality inspections before being loaded and shipped.

transportation

As we know, steel structure building has many parts, in order to make you clear and reduce the site work, we’ll mark each part with labels and take photos. In addition, we also have rich experience in packing. We will plan the packing location of the parts and the maximum use space, as far as possible to reduce the number of packing for you, and reduce the cost of shipping.

You may be worried about the problem of unloading. We put an oil wire rope on each package of goods to ensure that after the customer receives the goods, they can directly pull the whole package of goods out of the box by pulling the oil wire rope, saving time, convenience and manpower!

Steel structure construction

The components are transported to the construction site for foundation preparation and foundation construction, a critical step in steel structure construction, as a solid foundation ensures the stability of the entire structure. During the on-site assembly phase, the client uses equipment such as cranes to lift the steel structure components into place and connect them via bolts or welding.

Acceptance of Steel Structures

After installation, the structure’s axis, elevation, and verticality must be thoroughly re-measured. Any deviations exceeding the standard must be fine-tuned using tools such as jacks and guy ropes. After each unit is completed, a supervisory inspection will be conducted to check component position deviations, bolt tightening, weld quality, and structural stability. Only after passing these inspections can the next step be initiated.

Safety management is implemented throughout the entire installation process. During lifting, a dedicated person is assigned to direct the work. The load capacity of the lifting equipment is checked before lifting, and a safety factor of 6 or greater is required. Workers working at heights must wear safety belts, and a temporary operating platform must be established on the work surface. Site scrap materials are cleaned daily to avoid safety hazards. In the event of severe weather such as strong winds (≥10.8 m/s) or heavy rain, lifting operations must be stopped immediately and installed components must be secured. A series of measures are implemented to ensure safe and orderly construction and high-quality completion of the steel structure installation project.

The advantage of steel structure construction lies in its modular nature, which can significantly shorten construction time and reduce on-site operational risks.

prefabricated Steel Structure Standard codes

Chinese Standards

The GB (National Standard) and JGJ (Construction Industry Standard) series specify pertinent standards in China. For instance, GB 50009 deals with load calculations, whereas GB 50017 covers design standards. By taking into account regional socioeconomic and environmental factors, these guidelines guarantee that projects satisfy durability, fire resistance, and seismic criteria.

KHOME strictly follows these standards in all projects, guaranteeing safe and reliable structures. We continuously update our knowledge to provide clients with the latest solutions.

International Standards

International Standards Eurocode, ASTM, and ISO are examples of international standards. They guarantee constant safety and dependability around the globe by defining steel characteristics, design techniques, and testing specifications. For instance, ISO focuses on sustainability and environmental impact, whereas ASTM addresses mechanical attributes and chemical composition.

Any standard demands that customers may have should be communicated as soon as feasible so that we can consider them throughout the design phase.

K-HOME’s prefabricated steel structures have been designed and successfully constructed in numerous countries, including Mozambique, Guyana, Tanzania, Kenya, and Ghana in Africa, the Bahamas and Mexico in the United States, and the Philippines, Malaysia, and Cebu in Asia. We are well-versed in the building standards and climate conditions of each country and can provide customized designs that successfully pass local government approvals and demonstrate safety, durability, and cost-effectiveness.

Applications of PEB Steel Structures

Industrial Steel Buildings

Because steel buildings require big expanses and have a high load capacity, they are frequently seen in factories, warehouses, and logistics hubs. Quick extension or modification to accommodate changes in the production line is made possible by the modular architecture.

For instance, adding prefabricated elements to a steel warehouse without interfering with operations allows for easy storage expansion. They are appropriate for challenging industrial settings due to their seismic and wind resistance, which safeguards workers and equipment. Functionality is another priority for industrial steel structures, which incorporate fire and ventilation systems for increased effectiveness. Smart technology is being used more and more for real-time monitoring and management as a result of automation trends.

In summary, steel structures’ adaptability and dependability increase industrial applications’ output.

Commercial steel Buildings

Steel buildings are frequently seen in hotels, workplaces, and shopping centers. They enable quick construction and adaptable space design. Open layouts are supported by large-span frames, which make it simple for companies to modify interior areas.

Because of its small weight, high-rise structures’ foundation loads are reduced, which lowers total expenditures. They can incorporate energy-saving devices like solar panels or green roofs for sustainability.

Long-term functioning with little maintenance is ensured by durability. Steel structure building are used in many commercial sites across the world, demonstrating its dependability and beauty.

Indoor Badminton Court

Learn More >>

Agricultural Steel Buildings

Agricultural Steel Buildings refer to Steel Structure buildings for agricultural production and processing, such as grain depots, livestock and poultry farms, greenhouses, and agricultural machinery repair stations. All of Khome steel farm buildings are manufactured to the specifications of their designers, whatever type of agricultural building you design, we can help you make it a reality.

Residential and Additional Uses

Steel structures are increasingly being used in temporary buildings, public spaces, and residential settings in addition to commercial and industrial settings.

They draw attention for their quick construction and environmental friendliness, making them perfect for holiday houses or reasonably priced housing. Public facilities like schools, hospitals, and stadiums use them for large, comfortable spaces. Temporary structures, such as exhibition tents or emergency shelters, highlight their portability and reusability. Across these applications, steel structures show adaptability and sustainability for diverse user needs.

Pre-engineer Steel Structure Installation

Pre-Installation Preparation

Preparation includes site survey, foundation construction, and component inspection. These steps are crucial for project success. First, the team conducts a detailed site survey to assess terrain, soil conditions, and transport routes, ensuring a safe installation environment. Then, foundation work begins, such as pouring concrete bases, which must meet design load requirements for stability. Prefabricated components are strictly inspected before delivery for dimensions and anti-corrosion treatment to avoid assembly issues.

On-Site Assembly Steps

Assembly starts with lifting components into place using cranes. The team first installs primary load-bearing elements like columns and beams, connecting them with bolts or welding for rigidity.

Secondary components like braces and roof panels are added step-by-step. Each step requires leveling and fastening checks. Precision and teamwork are essential, following drawings and specifications. The modular nature allows parallel tasks, shortening the timeline. After assembly, final tests include load tests and visual inspections.

Post-Installation Inspection

This final step ensures structural safety and performance. Checks include connection integrity, anti-corrosion coating, and overall alignment. Teams use tools like ultrasonic testers to assess quality. Load tests simulate real-use conditions to verify the structure’s capacity meets design standards.

K-HOME provides full installation services with a professional team experienced in domestic and international projects. We handle complex assembly environments and offer full supervision and training to optimize processes, reduce delays, and control costs.

Through global resource integration, KHOME responds quickly to client needs, ensuring timely project completion even in urgent situations.

why K-HOME Steel structure?

As a professional PEB manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

Some common questions about steel structure buildings

Is the construction period for Steel Structures long?

No. Compared to traditional methods, steel structure building is usually completed significantly more quickly because to prefabricated modular design. Depending on the size of the project, on-site assembly can be completed in a matter of weeks or months.

How is the foundation for a Steel Structure built?

It requires a stable foundation, usually concrete, to ensure overall stability. The design is customized based on load and soil conditions.

Does K-HOME provide installation services?

Yes. KHOME has professional installation teams for both domestic and international projects. We offer on-site guidance and full services for efficient project completion.

How should a steel-structured building be maintained?

Examine anti-corrosion coatings and connecting points on a regular basis. Clear away collected dust and debris as soon as possible.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.