prefabricated steel buildings & PEB building manufacturer

pre-engineered steel building / PEB building / steel fabricated buildings / Steel Structure Building

The use of prefabricated steel buildings in industrial and commercial applications has gradually become the norm. Compared to traditional concrete buildings, prefabricated steel structures stand out due to their unique advantages. For example, the use of steel plates or steel sections instead of reinforced concrete significantly improves the building’s strength and earthquake resistance. Furthermore, the combination of factory-fabricated components and rapid on-site installation significantly shortens the construction period. More importantly, the reusable nature of steel helps reduce construction waste and promotes environmental protection.

K-HOME’s prefabricated steel Buildings: Engineered for Global Standards & Local Needs

Prefabricated steel buildings are building systems that use steel as the primary load-bearing material. Through precise fabrication, connection, and assembly, form strong, durable structures capable of withstanding a wide range of loads. These steel buildings are fully customizable, requiring technical design, fabrication, and on-site assembly according to local building codes and climatic conditions.

As a leading prefabricated steel building manufacturer in China, K-HOME delivers structures compliant with Chinese GB standards while maintaining global adaptability. Whether for steel warehouses, factories, or agricultural facilities, our steel structure buildings offer unparalleled durability, cost-effectiveness, and rapid construction, making them the future of sustainable infrastructure.

Standard comparison table of common steel materials:

| Chinese GB standard | American (ASTM) standard | European (EN) standard |

|---|---|---|

| Q235 | ASTM A36 | S235 |

| Q355 | ASTM A572 Gr.50 | S355 |

How to cope with international standards in design and manufacturing?

- Adjust material grades according to the standards of the project location.

- Design according to the load combination of the project location.

- Third-party testing agencies can assist in verifying standards compliance

buy direct from the manufacturer | k-hOME

Before selecting a prefabricated steel structure building manufacturer, it’s important to thoroughly research and consider factors such as the company’s reputation, experience, the quality of materials used, customization options, and customer reviews. Additionally, obtaining quotes and consulting with representatives from these companies can help you make an informed decision based on your specific project requirements.

K-HOME offers prefabricated steel buildings for various applications. We provide design flexibility and customization.

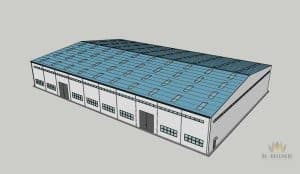

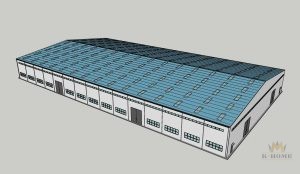

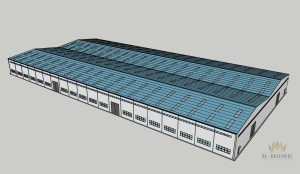

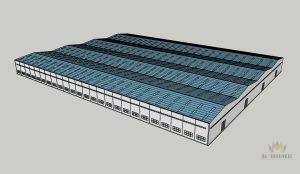

Mainstream prefabricated steel structure building form | portal steel structure

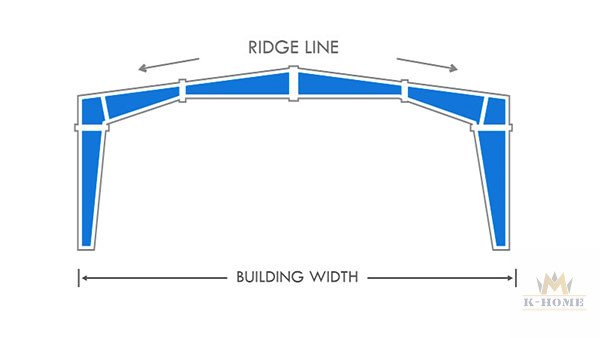

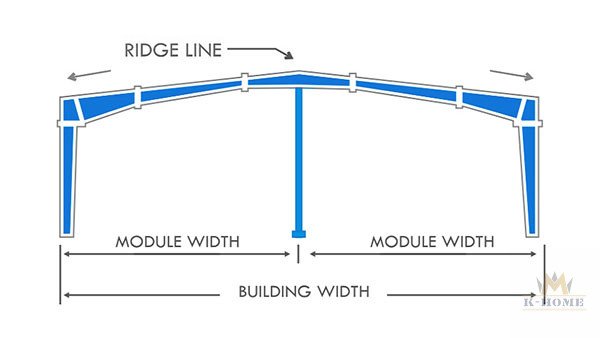

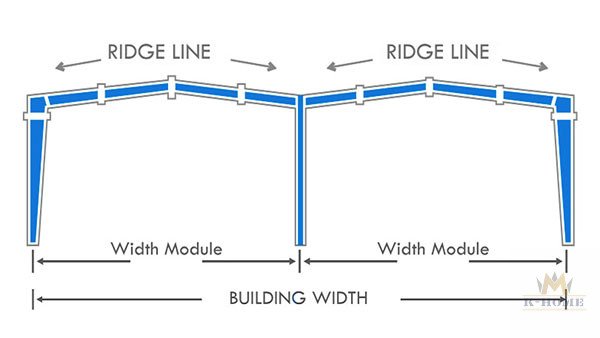

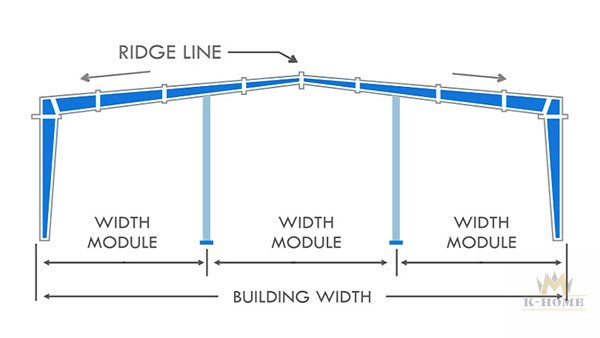

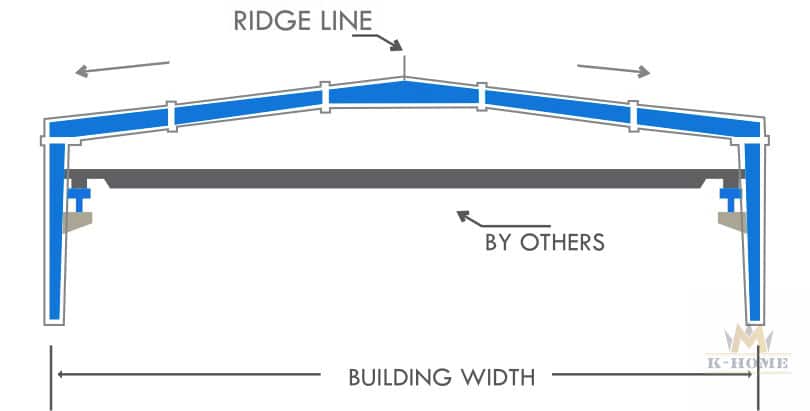

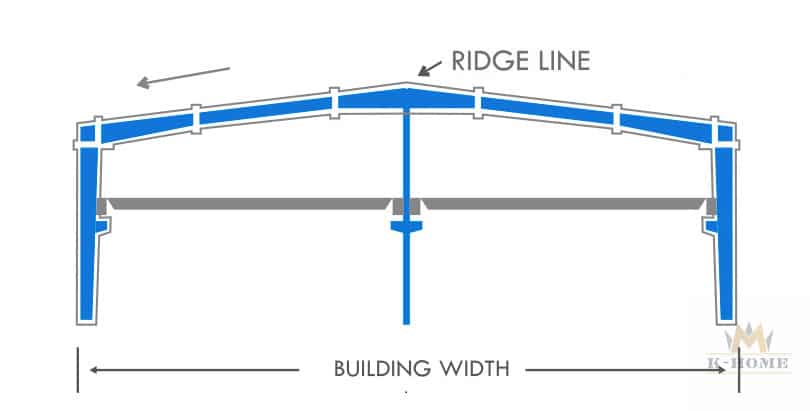

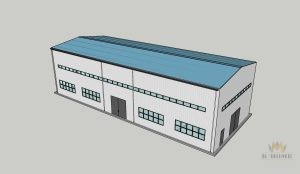

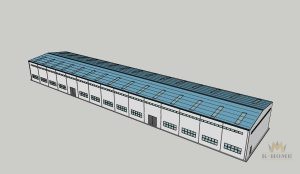

The portal steel frame system is one of our most mature solutions. Also known as a clear span steel structure, the steel portal frame is designed for single-story buildings requiring large open spans, making it particularly well-suited for applications such as warehousing, logistics, and industrial plants.

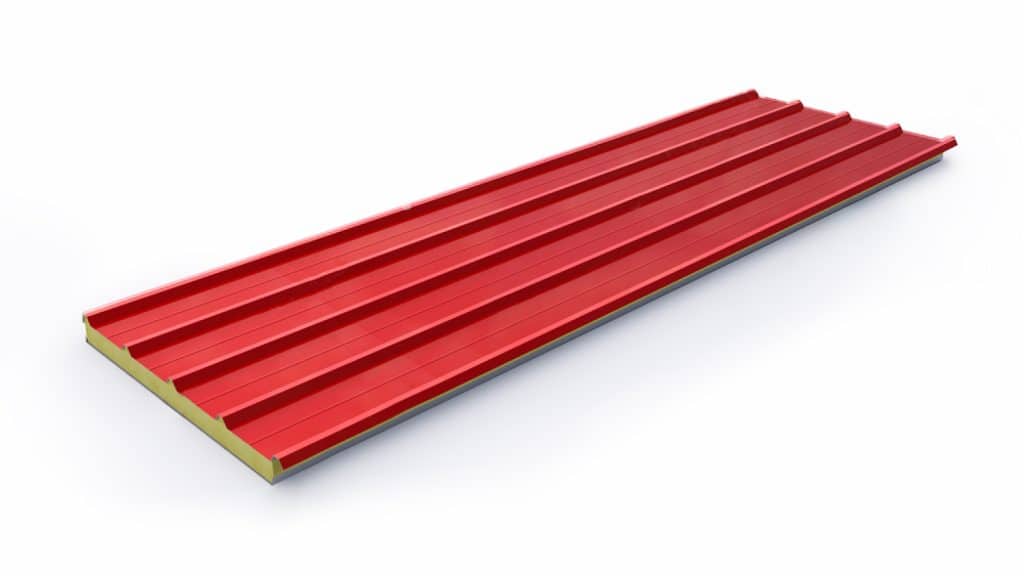

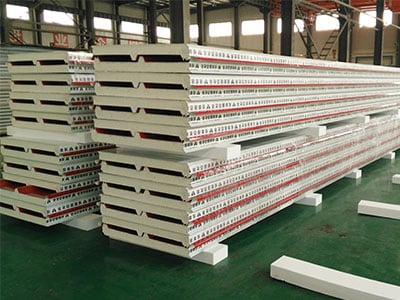

The load-bearing structure of our portal frame utilizes a variable-section or uniform-section solid-web frame, while the enclosure system utilizes a single-story steel structure with a lightweight steel roof and lightweight exterior walls. The entire steel frame structure consists of a load-bearing skeleton, purlins, wall beams, supports, walls, roof, and an insulation core. It features simple load-bearing, clear force transmission paths, rapid component fabrication, ease of factory processing, and a short construction period.

Portal steel frame structure type

clear-span double-sloped double-span double-sloped multi-span mult-sloped multi-span double-sloped clear-span with overhead crane double-span with overhead crane

Most Popular Portal Steel Structure Building Sizes

Key Components of Prefabricated Steel Buildings

Prefabricated steel building mainly combined by 5 parts: Steel Structure, roof system, wall system, window and door, and accessories. Let’s introduce them one by one in detail.

Steel Structure

Main steel mainly includes beam and column, the steel column is Hot roll H-section Q345 material, it includes corner column, the steel column quantity is changeable, it was calculated according to the area, the local environment, the standard distance also call interior bay are 6m.

Angle Channel-C H-Beam I-Beam Steel Columns Tie rods Purlins Cross bracings

Roof System

The roof system mainly has following parts:

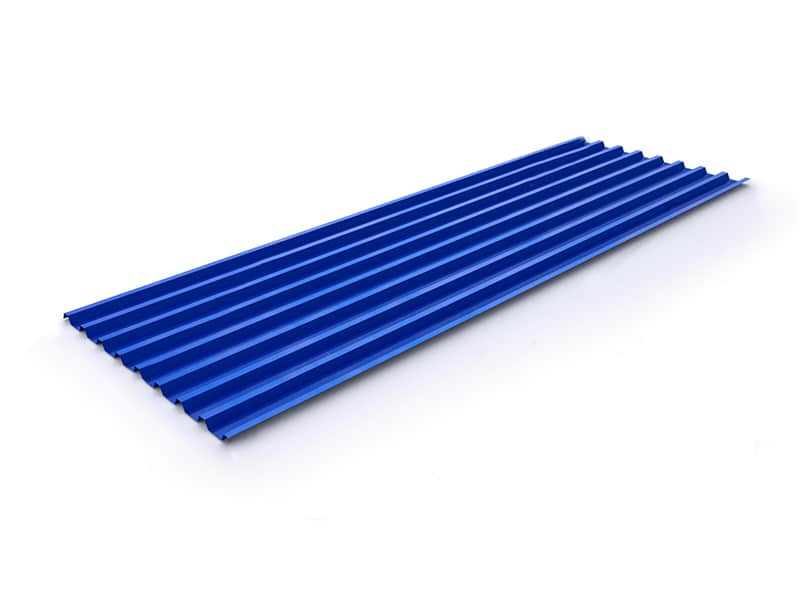

- roof panel/Single steel board, this mainly based on the local temperature.

- Ventilator: it also has turbo and ridged ventilator 2 kinds.

- Sky light: this is mainly used to give more light.

- Water gutter: this is optional, the water gutter are popular used in rainy weather.

Wall System

Wall panel/single steel plate: it is the same with the roof system.

Windows and doors

We have 100 types of windows and doors. You can choose from our catalog, or we can help you design a special one.

Accessories

Beside the main part in important, we also pay attention to the accessories, such as crews, bolts, and glue, these consideration will make the building modern and sleek.

Cost of prefabricated steel buildings

In the field of steel structure construction, price is a concern for every client. However, due to the diversity and complexity of steel structure projects, prices are not fixed. As a company with multiple qualifications and years of construction experience, K-HOME is committed to providing clients with one-stop quotation services to ensure that every client receives the most reasonable price.

The cost of prefabricated steel buildings are influenced by many factors, including but not limited to the following:

- Project Scale: The size and complexity of the project directly affect the quote. Large, complex projects require more manpower, material resources, and time, and therefore are relatively expensive.

- Material Cost: The cost of materials such as steel, connectors, and coatings is also an important component of the quote. Prices vary significantly between different brands and specifications of materials, so choosing the right materials for the project is key to controlling costs.

- Construction Time: The length of the construction period also affects the quote. Urgent projects may require additional resources, increasing costs.

- Geographic Location: Factors such as construction costs and labor costs in different regions also affect the quote.

K-HOME has a professional technical and construction team that can provide clients with integrated engineering solutions from planning, design, construction, to maintenance. Our quotation service includes the following steps:

- Needs Analysis: We understand the client’s specific needs and project requirements, including project scale, structural form, and material requirements.

- Schematic Design: We provide multiple feasible solutions based on the client’s needs and conduct a detailed cost analysis.

- Quotation Calculation: Based on the schematic design and cost analysis, we provide a detailed quotation list, ensuring that every cost is clear and transparent.

- Contract Signing: After both parties reach an agreement, we sign a formal construction contract, specifying the scope of work, price, and construction period.

Construction process of prefabricated steel structure buildings

Steel structure construction generally involves the following steps:

- Material Preparation: Procurement and processing of qualified steel materials according to the design drawings.

- On-site Foundation Construction: Excavation and concrete pouring of the foundation according to the design requirements.

- Steel Structure Installation: Delivery of prefabricated steel components to the construction site for assembly and welding according to the design drawings.

- Connection and Reinforcement: Ensure secure connections between components and perform reinforcement as necessary.

- Completion Inspection: Upon completion, the structure undergoes inspection and testing to ensure it meets the design requirements.

Application of prefabricated steel buildings | Steel Structure Solutions

Prefabricated steel structures, with their exceptional strength, flexible customization, and fast construction cycles, have become the preferred solution for modern industrial, commercial, and agricultural construction. In the industrial sector, prefabricated industrial steel buildings are widely used in a variety of manufacturing facilities, including high-standard production workshops, specialized steel welding shops, efficient auto repair shops, and large-scale storage facilities, fully demonstrating the advantages of pre-engineered steel building systems in industrial applications.

The commercial sector has also witnessed the rapid development of steel structure buildings. From basketball stadiums that meet the needs of professional sporting events, to large-scale supermarkets that cater to mass consumption, to storage centers that support modern logistics systems, prefabricated steel structures, with their large spans and fast construction times, perfectly meet the dual functional and economical requirements of commercial buildings.

As a professional manufacturer, K-HOME is deeply aware of the specific building requirements of various industries. Through standardized prefabricated components and flexible assembly methods, it provides optimal steel structure building solutions for different application scenarios.

prefabricated Industrial Steel Buildings

prefabricated Agricultural Steel Buildings

prefabricated Commercial Steel Buildings

Indoor Badminton Court

Learn More >>

why K-HOME Steel building?

As a professional PEB manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.