What is Insulation for Steel Buildings?

Insulation for a steel building is the strategic installation of specialized materials within its walls and roof to create a thermal barrier. These barriers effectively prevent heat transfer, reduce energy consumption, and improve indoor comfort.

The Importance of Thermal Insulation for Steel buildings

Thermal insulation is a crucial protective system. It is essential for any functional steel structure building. Its main advantages include:

- Maintaining stable indoor temperature: Steel structure buildings are often large in area. Due to steel’s good thermal conductivity, it is easily affected by fluctuations in external temperature. The Thermal insulation can effectively isolate hot and cold air from the outside, reducing indoor temperature fluctuations and providing a stable working environment for workers and equipment.

- Improving energy efficiency: Steel structure workshops without insulation layers consume a lot of energy to heat the interior in winter and a lot of energy to cool it in summer. Thermal insulation can significantly reduce this energy consumption, lowering the factory’s operating costs.

- Extending building lifespan: Insulation not only regulates indoor temperature but also protects the steel structure from external environmental factors such as rainwater, snowmelt, and ultraviolet radiation, thereby extending the building’s lifespan.

Selection and treatment of thermal insulation materials

Fiberglass Wool Insulation

Fiberglass insulation is the most common and cost-effective option, available in both roll and felt forms. This material offers excellent fire resistance and thermal insulation. It is typically laid on a steel frame structure, working in conjunction with steel panels and wire mesh to form an insulation system. Its outstanding cost-effectiveness makes it an ideal solution for budget-sensitive traditional warehouse and workshop projects.

The thermal insulation structure consists of the following layers: steel structure base layer → galvanized steel wire mesh → glass fiber wool (density ≥120kg/m³) → finishing layer (steel plate).

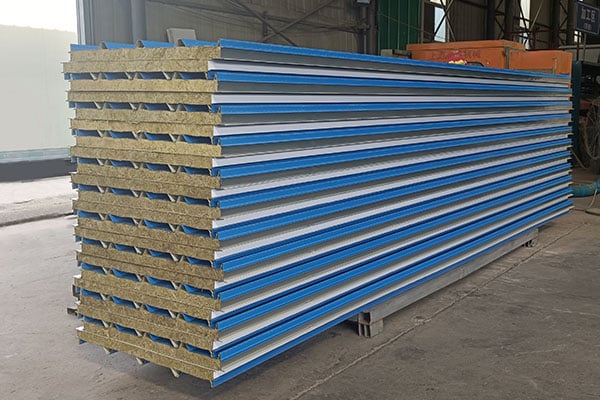

Steel building insulation panels

Insulated Metal Panels, commonly known as “sandwich panels”, are composite panels made of two layers of metal sheets with an insulating material (such as rock wool, foam, or polyurethane) sandwiched between them. They are commonly used in the roofs and walls of steel-framed buildings, providing an integrated solution that combines structure, insulation, and aesthetics. In addition to good insulation performance, sandwich panels also offer excellent waterproof and fireproof properties. While this insulation material is slightly more expensive, it makes it an ideal choice for facilities with stringent requirements for energy efficiency, temperature control, and durability.

Sandwich panel installation process: Measurement and layout → Purlin installation (spacing ≤ 1.2m) → Sandwich panel hoisting (protection against breakage) → Self-tapping screw fixing (spacing 300-400mm) → Sealing of panel seams with silicone weather-resistant sealant.

When selecting and constructing thermal Insulation, it is essential to comprehensively consider material properties, construction techniques, and subsequent maintenance and testing. These factors ensure that the insulation layer can effectively protect the steel structure factory building for a long period. Through scientific and rational design and construction, steel structure factory buildings can better adapt to various climatic conditions, providing a more stable and efficient working environment for industrial production.

How to choose the right Thermal insulation for a specific scenario?

Choosing the right insulation material for a specific scenario requires comprehensive consideration of environmental conditions, functional requirements, and cost-effectiveness. Here are the key points:

Selection by Ambient Temperature

- Extremely Cold or Hot Regions: The primary goal is to reduce heat transfer. Polyurethane foam boards are recommended, as they have extremely low thermal conductivity and effectively block external high or low temperatures.

- Special Temperature Scenarios: Utilize high-temperature resistant materials such as rock wool to ensure stability and fire safety under extreme temperatures.

Selection by Functional Requirements

- High fire resistance requirements: Rock wool (Class A fire resistance) or glass wool (inorganic material)2

- Sound insulation requirements: Rock wool or glass wool (with a porous fiber structure).

- Waterproof and moisture-proof: Composite materials with an aluminum foil moisture barrier are ideal, as they effectively block moisture for a long time.

Selection by cost-effectiveness

- Budget First: Glass wool is one of the most cost-effective and proven options.

- Long-Term Value and Environmental Friendliness: Although the initial investment is higher, the superior performance and durability of insulated sandwich panels deliver long-term energy savings.

Cost Analysis of Thermal Insulation for Steel Structure Buildings

In most cases, the cost of insulation for steel structures is estimated, not fixed. It is influenced by a combination of variables, from material selection and building dimensions to labor costs and insulation ratings. Understanding these factors will help you make decisions that better align with your budget and performance needs.

Key factors affecting Thermal insulation costs

Insulation Material Selection:

- Basic Type: Glass wool offers the best cost-performance ratio, suitable for warehouses or workshops with limited budgets and no extreme temperature control requirements.

- High-End Type: Sandwich panels are suitable for steel buildings with certain temperature control requirements. Sandwich panels can be categorized based on their insulation core material: EPS sandwich panels, rock wool sandwich panels, PU-sealed rock wool sandwich panels, PU sandwich panels, and PIR sandwich panels. Among these, polyurethane foam sandwich panels (PU)offer the highest insulation value and seamless sealing, effectively preventing condensation, but require professional installation.

Thickness and R-Rating

The R-rating is a standard for measuring the thermal insulation performance of insulation materials. A higher R-rating indicates better insulation, but also increases cost and material thickness.

Structure and Dimensions of Steel Building

Buildings with complex structures (such as those with multiple doors and windows or very high ceilings) require more labor and materials than simpler structures, significantly increasing labor costs.

Labor and Installation Methods

Installing roll-on insulation materials yourself can save on overall costs, but carries the risk of improper installation. Hiring a professional team will increase costs but ensure optimal performance and a long-term warranty. Specific labor costs vary depending on local conditions.

Cost estimation: How much do you expect it to cost?(2025)

Based on current market conditions, the overall insulation cost (materials and accessories only) for a 12*60m (360 square meters) steel structure building with no special requirements, using color steel plates as the maintenance material, is between $3,500 and $7,000. It’s important to note that this is only a basic reference range. For buildings with strict temperature control requirements (such as cold storage or temperature-controlled workshops), additional insulation materials may be needed, easily exceeding this cost range.

We recommend obtaining multiple detailed quotes from professional contractors based on the building’s specific purpose and local climate to make the most informed decision.

About K-HOME

——Pre Engineered steel Building Manufacturers China

Henan K-home Steel Structure Co., Ltd is located in Xinxiang, Henan Province. Established in the year 2007, registered capital of RMB 20 million, covering an area of 100,000.00 square meters with 260 employees. We are engaged in prefabricated building design, project budget, fabrication, installation of steel structure and sandwich panels with second-grade general contracting qualification.

Design

Every designer in our team has at least 10 years of experience. You don’t have to worry about the unprofessional design affecting the safety of the building.

Mark and Transportation

In order to make you clear and reduce the site work, we meticulously mark each part with labels, and all parts will be planned in advance to reduce the number of packings for you

Manufacturing

Our factory has 2 production workshops with large production capacity and short delivery time. Generally, the lead time is around 15 days.

Detailed Installation

If this is the first time for you to install the steel building, our engineer will customize a 3D installation guide for you. You don’t need to worry about the installation.

why K-HOME Steel building?

As a professional PEB manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

related blog

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.