How Much Does a Steel Building Cost?

Steel buildings are increasingly popular for industrial, commercial, and even residential applications due to their strength, versatility, and long-term cost savings. If you are planning to invest in a steel structure building, one of your first concerns will likely be: how much does a steel building cost? This detailed guide from K-HOME, a leading steel building manufacturer, will walk you through the factors influencing price, cost breakdowns, comparisons with traditional construction, future trends, and why choosing K-HOME can make your project easier and more affordable.

Key Factors That Affect Steel Building Costs

The steel building cost can vary widely depending on several factors. On average, the cost ranges from $40 to $80 per square meter, FOB China. The main factors affecting the cost of steel manufacturing buildings are:

Size and Dimensions

The total square footage and height of your steel building directly affect material and labor requirements. A small workshop or storage shed costs significantly less than a multi-story factory or warehouse. Even small changes in roof height or building width can increase steel usage and costs.

Building Design and Complexity

Simple rectangular or square buildings are the most economical, while complex designs featuring multiple spans, mezzanines, high ceilings, or special rooflines require more engineering and materials, driving up costs. Features like large windows, multiple doors, skylights, or aesthetic finishes also add to the total price.

Quality of Materials

Not all steel is created equal. Higher-grade, corrosion-resistant steel lasts longer but comes at a higher price. K-HOME sources premium steel that meets international standards, ensuring durability and reducing maintenance costs in the long run.

Location and Logistics

Transportation costs are also one of the steel building costs. Delivery costs vary based on the site location. Remote sites, areas with difficult access, or sites requiring special handling can increase shipping and installation costs. Planning logistics in advance can help control expenses.

Additional Features

Optional features, such as insulation, climate control, partition walls, and specialized flooring, will increase the initial investment. For example, a cold storage warehouse or a climate-controlled office inside the steel building will cost more than a basic workshop structure.

| Cost Component | Estimated Cost per Sq. Ft. |

| Steel Building Kit | $35-$45 |

| Insulation | $2-$5 |

| Doors and Windows | Varies based on customization |

| Foundation | Depends on geological conditions |

| Labor and Installation | Depends on labor costs in each country |

| Permits and Fees | Fees vary by country |

Detailed Cost Breakdown: Materials, Labor, and Installation

Knowing where your money goes helps you plan effectively. Generally, a steel building’s cost can be divided into three major components:

Material Costs

- Materials typically account for 50–60% of the total budget. This includes:

- Steel Frames: Columns, beams, and roof trusses that form the building’s skeleton.

- Roof and Wall Panels: Coated to resist rust and provide weather protection.

- Foundation Materials: Concrete slabs or footings to support the structure.

Using high-quality steel may cost more upfront but reduces maintenance and prolongs service life.

Labor Costs

Labor includes fabrication, assembly, and on-site installation. Depending on your region, labor can make up 20–30% of the total cost. Experienced installers not only ensure safety but also speed up the construction process, reducing the overall timeline and indirect costs.

Installation and Equipment

Large buildings may require cranes, scaffolding, and other specialized tools. Installation usually accounts for 10–20% of total expenses. K-HOME has long been involved in the steel structure industry, with particular expertise in industrial buildings with integrated overhead cranes. Our innovative “turnkey” solution fundamentally addresses the traditional pain point of separate steel structure and crane design and manufacturing. Through the integrated design and construction of the main structure and crane system, we ensure perfect compatibility and optimal performance of the entire system. This approach eliminates interface risks and coordination burdens for our clients, ensuring a smooth project process from construction to commissioning.

Steel Building vs Traditional Construction: A Cost Comparison

Many clients ask whether steel buildings are more cost-effective than traditional concrete or brick construction. Here’s a practical comparison:

| Feature | Steel Building | Traditional Construction |

| Material Cost | Moderate, stable | Often higher, varies |

| Labor Efficiency | Fast assembly | Labor-intensive |

| Durability | High, corrosion-resistant | Moderate, subject to decay |

| Maintenance | Low | Higher |

| Design Flexibility | High, easy to customize | Limited |

| Construction Time | Weeks to months | Months to over a year |

Steel buildings typically save 20–40% on construction costs and significantly reduce the time to complete a project. For factories, warehouses, or commercial buildings, the combination of speed, durability, and flexibility makes steel structures a highly attractive choice.

Future Steel Building Price Trends

Understanding future price trends can help you plan investments more strategically:

Steel Market Dynamics

Global supply and demand affect steel prices. Market fluctuations can impact building costs, so monitoring trends helps determine the best time to invest.

Advancements in Prefabrication

Modern prefabrication techniques reduce on-site labor and installation time, which can lower costs. Modular construction is becoming increasingly common for industrial and commercial projects.

Sustainable Practices

Recycled steel is gaining popularity, offering a more affordable and environmentally friendly alternative. Investing in sustainable materials can reduce costs over the life cycle of the building.

Regional Development

Rapid industrial development in certain regions may increase local demand for steel buildings, slightly raising prices. Working with an experienced supplier like K-HOME ensures you receive fair pricing regardless of local fluctuations.

About K-HOME

——Pre Engineered steel Building Manufacturers China

Henan K-home Steel Structure Co., Ltd is located in Xinxiang, Henan Province. Established in the year 2007, registered capital of RMB 20 million, covering an area of 100,000.00 square meters with 260 employees. We are engaged in prefabricated building design, project budget, fabrication, installation of steel structure and sandwich panels with second-grade general contracting qualification.

Design

Every designer in our team has at least 10 years of experience. You don’t have to worry about the unprofessional design affecting the safety of the building.

Mark and Transportation

In order to make you clear and reduce the site work, we meticulously mark each part with labels, and all parts will be planned in advance to reduce the number of packings for you

Manufacturing

Our factory has 2 production workshops with large production capacity and short delivery time. Generally, the lead time is around 15 days.

Detailed Installation

If this is the first time for you to install the steel building, our engineer will customize a 3D installation guide for you. You don’t need to worry about the installation.

why K-HOME Steel building?

As a professional steel building manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

Steel Building Size Recommendations

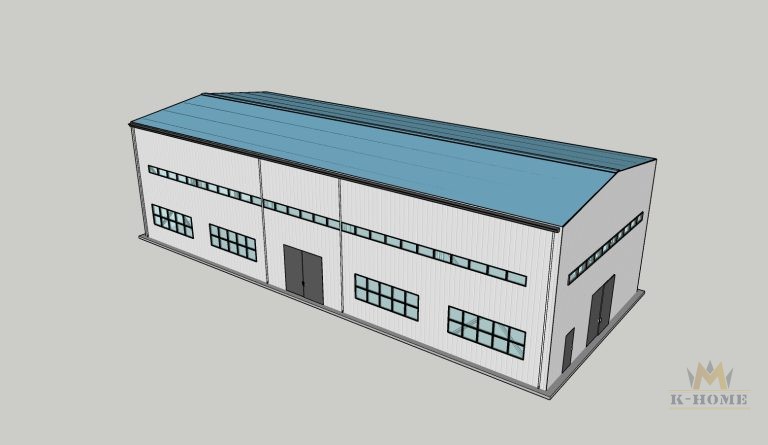

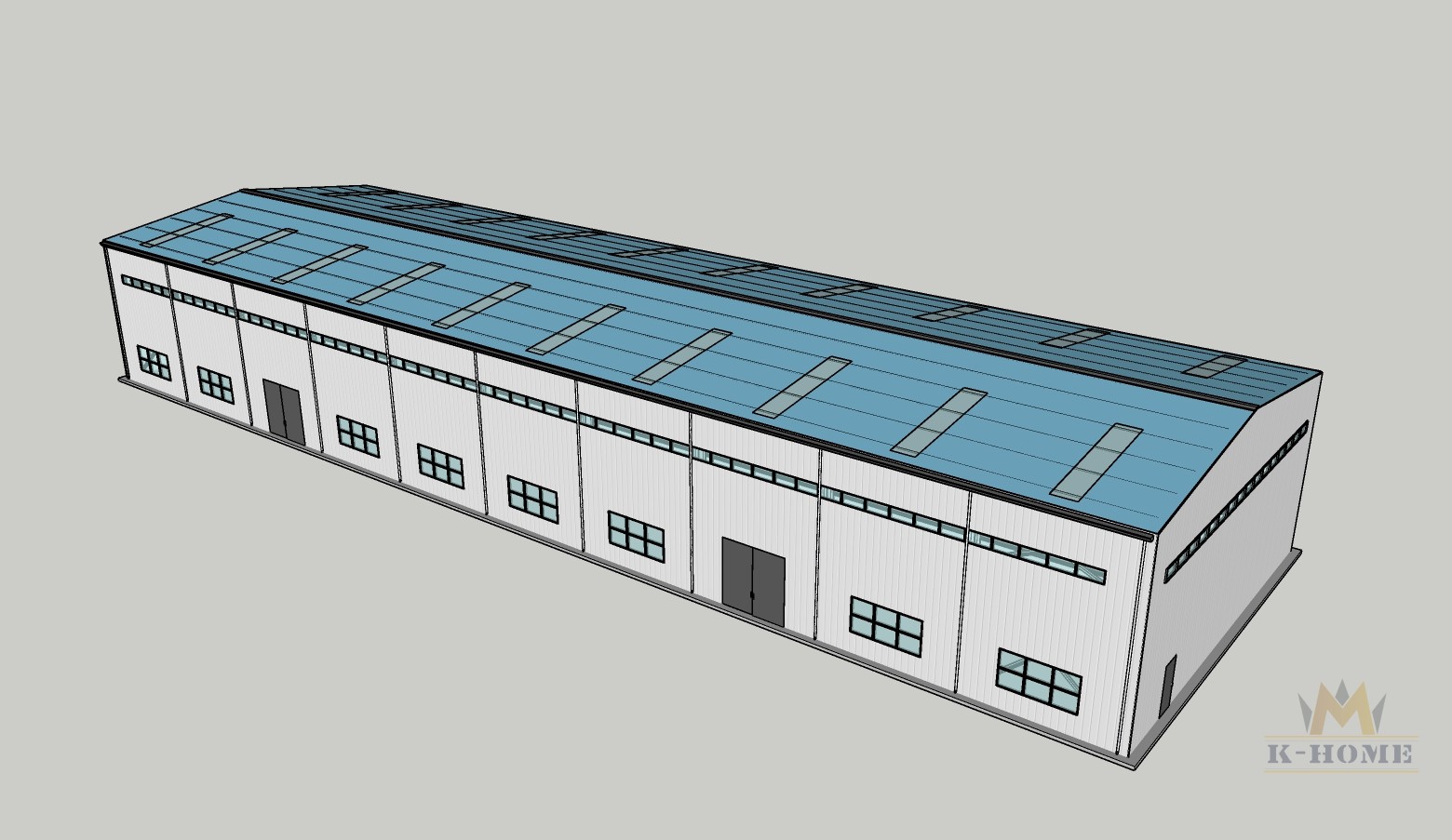

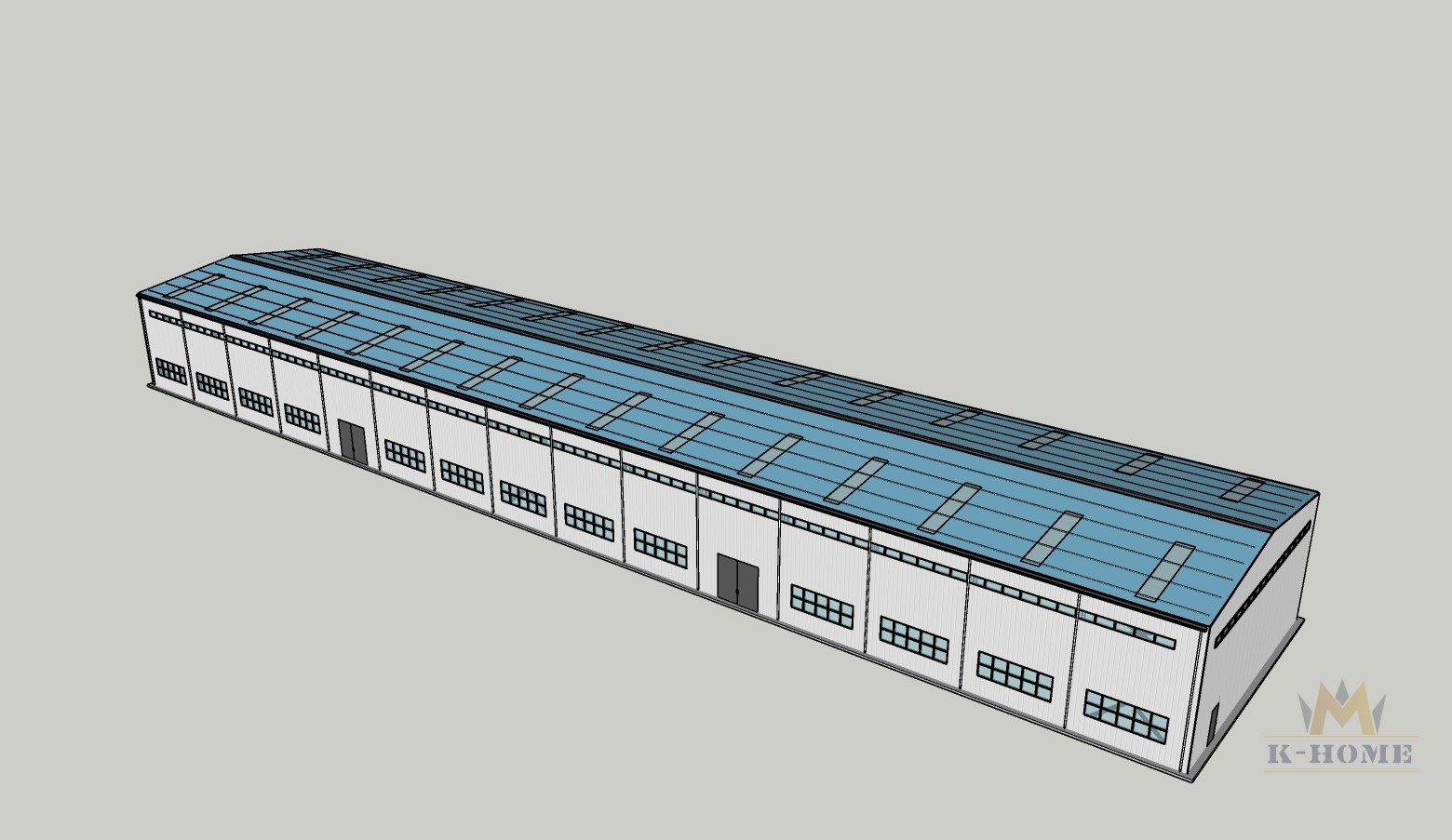

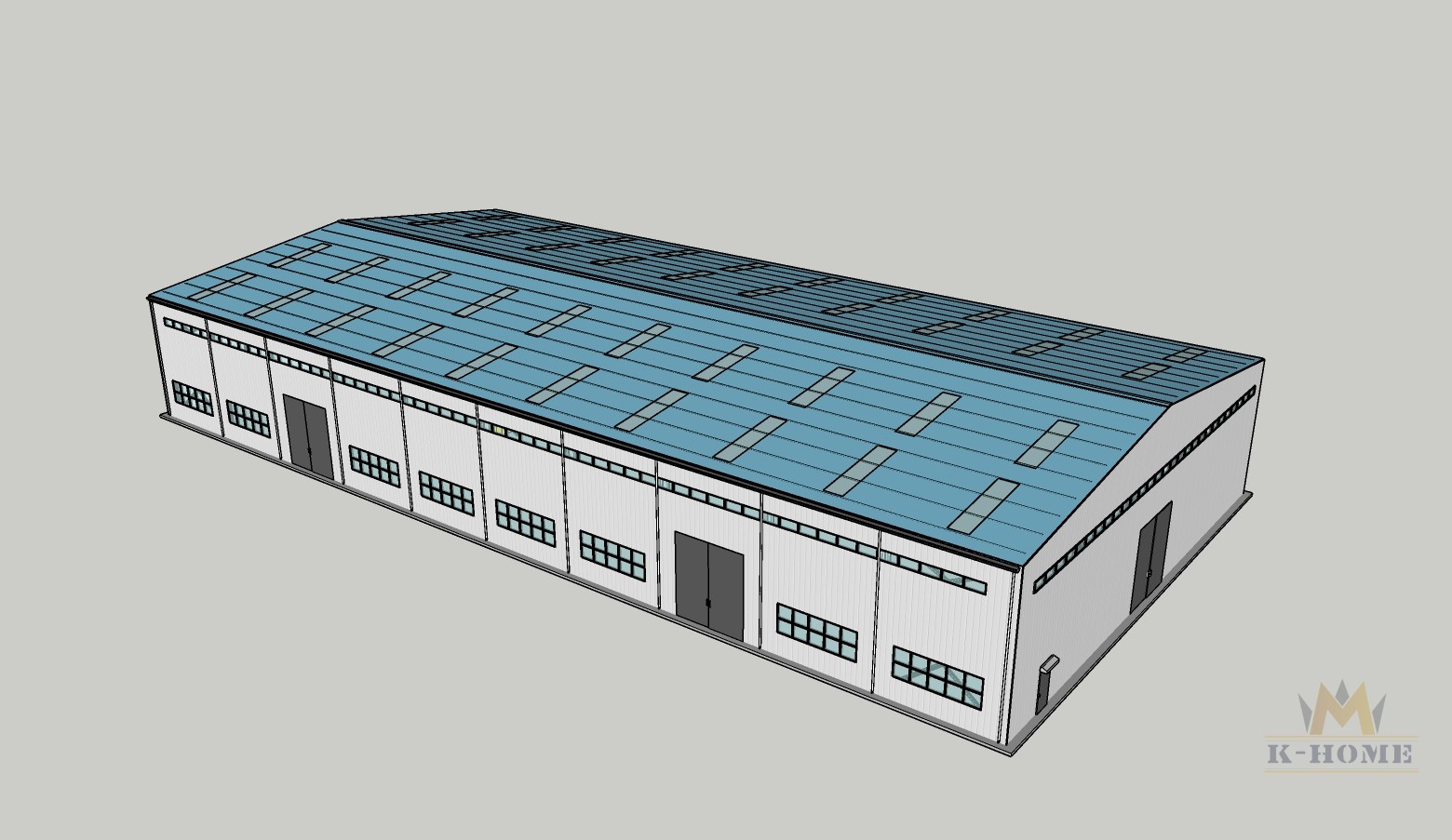

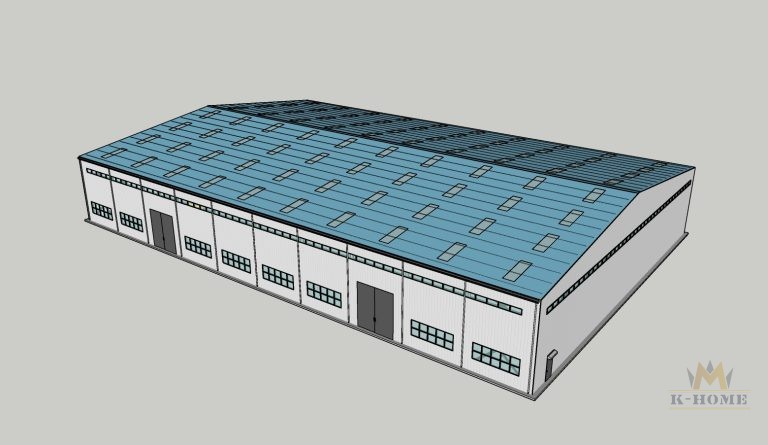

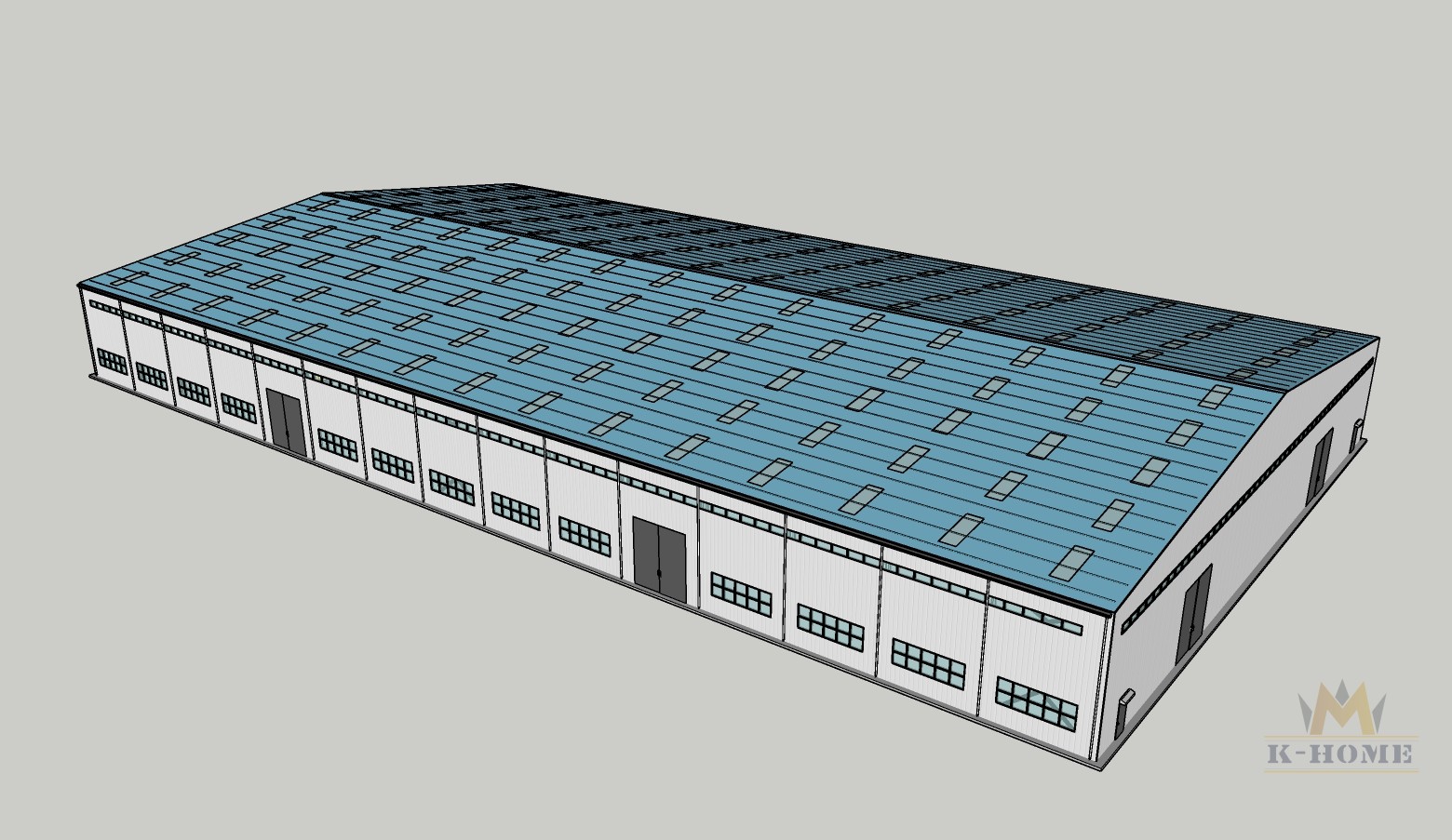

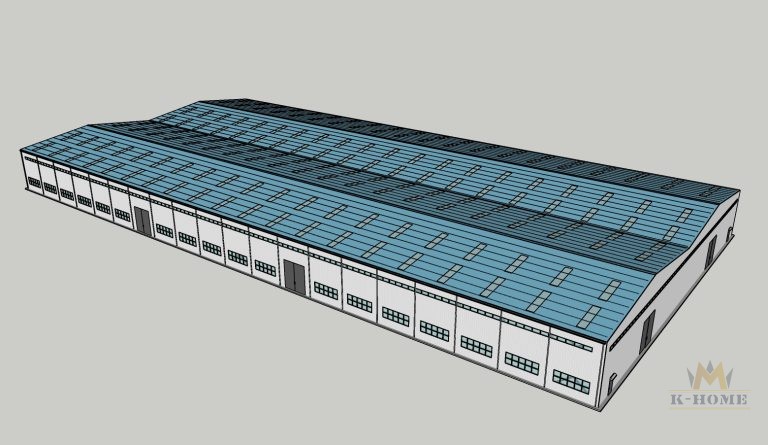

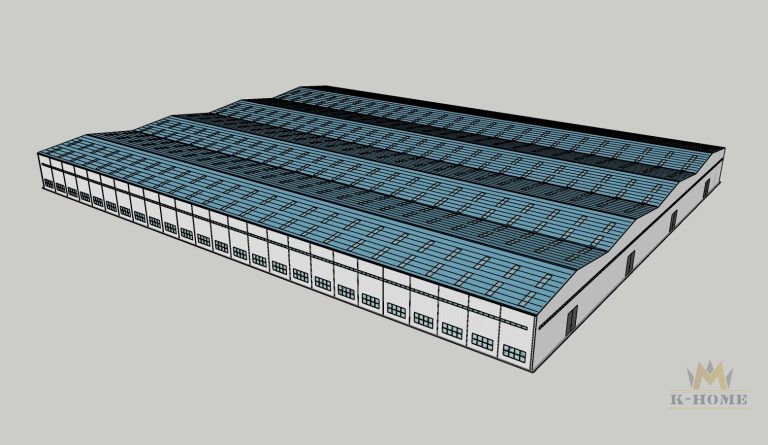

120×150 Steel Building (18000m²)

related blog

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.