What is Structural Steel Fabrication?

Structural steel fabrication refers to the process of cutting, shaping, assembling, and welding steel components into structural frameworks that meet precise engineering requirements. It bridges the gap between raw material and the finished building skeleton. Every fabrication step is carried out according to detailed design drawings and international standards, ensuring that the final product meets both safety and performance criteria.

K-HOME manufactures steel structures using high-quality steel from certified suppliers. Depending on structural requirements, we carefully select common grades such as Q345 and Q235, as well as internationally equivalent materials like ASTM A36 or A992. Each steel grade offers unique mechanical properties, such as yield strength, ductility, and corrosion resistance. We ensure material traceability throughout the entire process, from the first cut to final installation, guaranteeing consistency and reliability.

Structural Steel Fabrication Processes

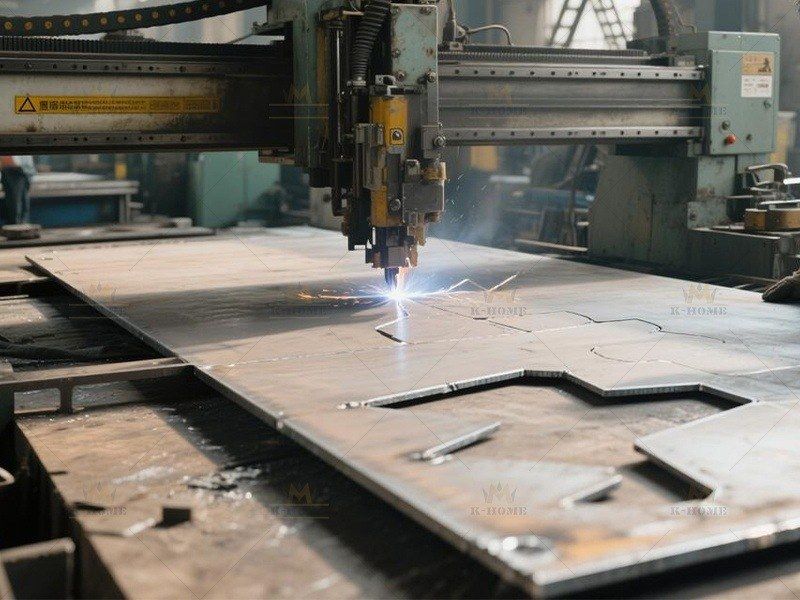

Precision Cutting and Forming

The fabrication journey begins with precision cutting. Using advanced cutting equipment, we ensure every steel plate and section is dimensionally accurate. Once cut, components are shaped through bending and rolling processes to achieve the desired form. These shaping methods are critical for producing complex geometries used in bridges, towers, and industrial frames.

Welding and Assembly

After forming, the components move to the assembly and welding stages. Welding is one of the most crucial steps in steel fabrication, as it determines the structural integrity of the entire framework. Our welders are certified under recognized standards such as AWS D1.1 and GB/T 12467, ensuring both precision and durability. Automated welding systems are also used to achieve uniformity and efficiency in large-scale production.

Surface Treatment and Coating

To protect steel components from corrosion and environmental damage, we apply surface treatments such as sandblasting, galvanizing, and epoxy or polyurethane coating. Each project’s coating system is customized based on its application—whether it’s a coastal bridge exposed to humidity or an industrial facility requiring chemical resistance.

Quality Inspection and Testing

At every stage, quality control is a non-negotiable principle. Our in-house inspection team conducts non-destructive testing (NDT), ultrasonic inspections, and weld visual checks to ensure compliance with international standards. Dimensional accuracy is verified using 3D measurement tools, and all results are documented for client transparency.

Key Considerations in Fabrication

Design and Engineering Coordination

The success of steel fabrication depends heavily on early coordination between designers, engineers, and fabricators. By integrating Building Information Modeling (BIM) into our workflow, we identify potential design conflicts before fabrication begins. This approach minimizes rework, reduces costs, and improves installation efficiency on-site.

Material Handling and Logistics

Proper handling and storage are essential to maintain material integrity. Components are stored in controlled environments to prevent rust or deformation. During transportation, we employ secure packaging and labeling systems to ensure that each part arrives safely and is easy to identify during assembly.

Compliance with Standards

Our steel structures comply with both Chinese and international standards, including GB, EN, and AISC codes. This compliance assures our clients that the fabricated steel can be safely integrated into projects anywhere in the world. Every product we deliver is accompanied by test certificates, inspection reports, and full documentation of its fabrication history.

Sustainability and Environmental Responsibility

We recognize our role in promoting sustainable construction. Steel is a fully recyclable material, and our manufacturing process minimizes waste by optimizing material usage. Energy-efficient machinery and responsible waste management practices contribute to reducing our environmental footprint.

Advantages of Structural Steel Fabrication

Superior Strength and Durability

Structural steel offers excellent load-bearing capacity while maintaining a relatively light weight compared to concrete. This combination allows for more open spaces and longer spans in architectural design. Our fabricated steel structures maintain high strength and durability, ensuring long-term performance under various environmental conditions.

Flexibility and Design Freedom

One of the greatest advantages of steel fabrication is design flexibility. Our engineers can create intricate shapes and customized designs that meet unique architectural visions. Whether for industrial plants, airports, or commercial centers, steel structures can be adapted to virtually any form without compromising safety.

Speed and Efficiency in Construction

Prefabrication at our facilities means that by the time steel components arrive at the construction site, they are ready for quick assembly. This drastically reduces on-site labor time and construction schedules. The result is faster project completion, lower costs, and minimized disruption to surrounding environments.

Quality Consistency and Reliability

Because our fabrication processes are highly controlled, every product we manufacture meets strict quality standards. From automated cutting to robotic welding, consistency is maintained across all production batches. This precision ensures that each component fits perfectly during erection, avoiding costly delays or modifications.

Sustainability and Cost-Effectiveness

Steel’s recyclability makes it one of the most sustainable materials available. Combined with efficient manufacturing and long service life, structural steel provides an excellent return on investment. Clients benefit not only from reduced maintenance costs but also from the environmental value of choosing an eco-friendly material.

Logistics and On-Site Assembly

After fabrication and inspection, components are packaged, labeled, and shipped to the project site. Efficient logistics planning ensures safe transportation, especially for oversized elements.

On-site assembly involves lifting, bolting, and welding. Pre-drilled holes, marked components, and modular assembly designs significantly reduce installation time. Our support continues beyond delivery, offering technical guidance during erection to ensure that every structure is assembled correctly and safely.

About K-HOME

——Pre Engineered steel Building Manufacturers China

Henan K-home Steel Structure Co., Ltd is located in Xinxiang, Henan Province. Established in the year 2007, registered capital of RMB 20 million, covering an area of 100,000.00 square meters with 260 employees. We are engaged in prefabricated building design, project budget, fabrication, installation of steel structure and sandwich panels with second-grade general contracting qualification.

Design

Every designer in our team has at least 10 years of experience. You don’t have to worry about the unprofessional design affecting the safety of the building.

Mark and Transportation

In order to make you clear and reduce the site work, we meticulously mark each part with labels, and all parts will be planned in advance to reduce the number of packings for you

Manufacturing

Our factory has 2 production workshops with large production capacity and short delivery time. Generally, the lead time is around 15 days.

Detailed Installation

If this is the first time for you to install the steel building, our engineer will customize a 3D installation guide for you. You don’t need to worry about the installation.

why K-HOME Steel building?

As a professional PEB manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

related blog

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.