General Steel buildings

Industrial Steel Buildings | Agricultural Steel Buildings | Commercial Steel buildings | Residential metal buildings

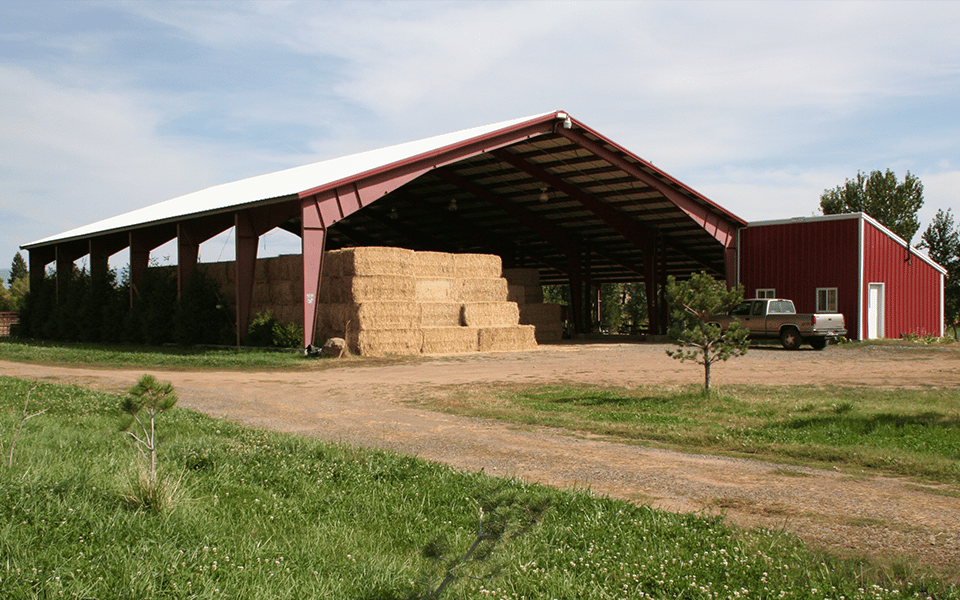

K-HOME general steel buildings are prefabricated steel building types. The prefab steel buildings can be custom designed according to customer needs. The development of general steel buildings is relatively rapid. We will find that prefabricated steel buildings can be seen everywhere, and prefab steel structure has been inseparable from our life.

K-HOME could provide you with different prefab steel building kits, it is currently widely used in the construction of large warehouses, factories, farms, camps, apartments, hospitals, schools, multi-store buildings, and other fields.

Related Industrial Metal Steel Buildings

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

Details Of Prefab Steel Structure Warehouse Building

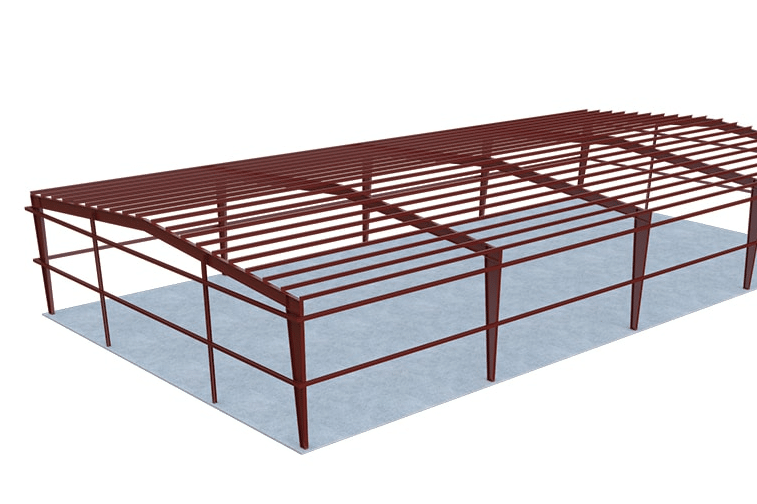

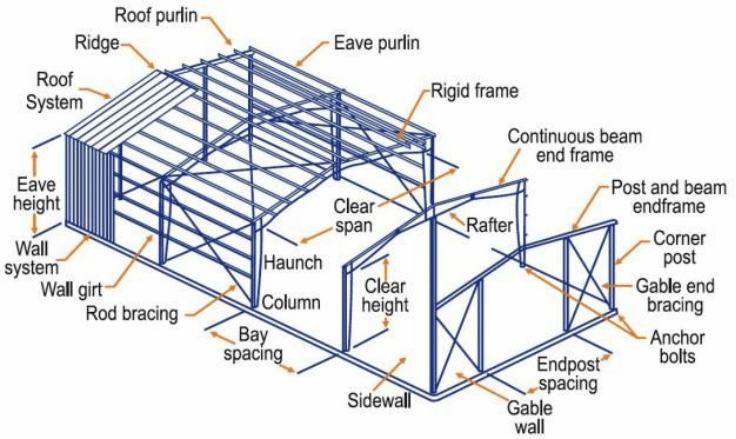

The steel structure warehouse building structure is mainly divided into three parts: Main Structure, Containment System, and Roofing System.

The main structure includes steel columns and steel beams, which are the main load-bearing structures. It is usually processed from Q345B steel plate or section steel to withstand the weight of the entire building and external loads.

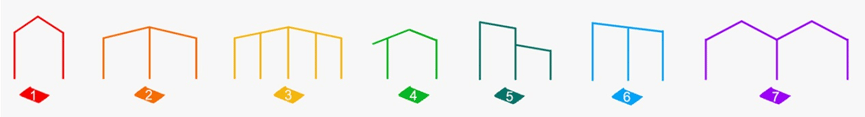

Here are some different steel frame types:

The wall enclosure system mainly has the following two methods:

Metal Plate Enclosure Structure

The metal plate enclosure structure is a kind of light wall structure plate that does not require load-bearing. It is composed of light color steel plate or color steel sandwich panel. The core material of the color steel sandwich panel can be glass fiberglass wool, and polyurethane or Foam core materials, but the current foam core materials are not recommended because the foam core materials do not have fire resistance. It should be noted that the single-layer color steel plate does not have the performance of heat preservation and heat insulation.

Load-Bearing Wall

The load-bearing walls are mainly filled with various lightweight filling materials, such as hollow block aerated concrete blocks, prefabricated pre-stressed concrete perforated plates, steel mesh plastic wall panels, and light steel keel plus Panel wall, and so on. The bottom wall can also be made of ordinary new earth brick masonry. The roof structure generally adopts a straight system, or light corrugated steel plate cover and color steel profiled board.

There are generally three types of roofing system materials:

- Single-layer color steel plate.

- The use of single-layer color steel plate + thermal insulation cotton + steel wire mesh enhances thermal insulation.

- Outer roof panel + thermal insulation cotton + inner roof panel or sandwich panel color steel plate.

In order to save energy and indoor daylighting, daylighting panels and daylighting panels are generally added to the roof at the same price as the roof panel. You can also design a roof air floor at the ridge to enhance indoor ventilation.

*Foundation

The foundation is the load-bearing component below the ground of the building. It bears all the loads from the upper structure of the building and transmits the external load and the main structure’s own load to the foundation to stabilize the entire building. The foundation is an important part of the building.

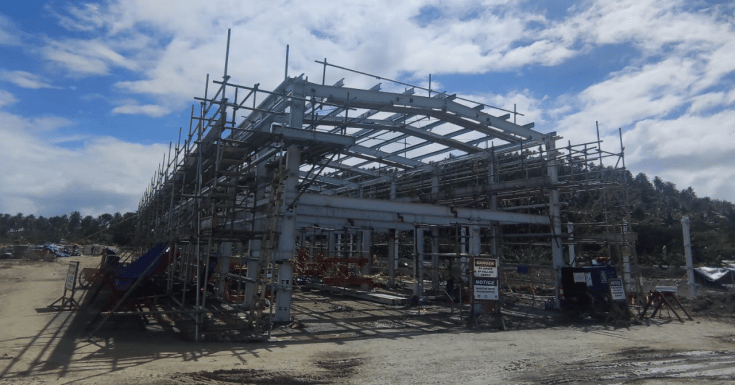

*Connecting Bolt

The various components or parts are connected by welding, bolts, or rivets. It can reduce on-site welding and make steel structure installation easier and faster.

K-HOME STEEL WAREHOUSE ADVANTAGES

Low Maintenance

Durable and easy to repair: The prefab steel structure of general professional design can withstand harsh weather, and only requires simple maintenance. The service life can reach more than 50 years.

Space Saving

The warehouse can adopt a clear span structure, that is, an open area that does not require any structural support, which means more working space. The design width of the clear span ranges from 100 feet to 300 feet.

Low Cost

The construction speed is fast, the construction period is at least one-third shorter than that of the traditional residential system, and reduce the cost by 5-10%. Speed up capital turnover and greatly improve investment efficiency.

Customizable

We provide reasonable customized plans for steel structure warehouses of various lengths, widths, and heights. We also provide other optional features, such as Windows or skylights, ventilation systems, entrance systems, drains, and downpipes, etc.

Sturdy

The steel structure has high strength and is suitable for the structure with large span, high height, and heavy load; at the same time, the steel structure has good toughness and material reliability, can withstand earthquakes, typhoons, and other natural disasters.

Flexible

Prefab steel buildings are expandable,K-HOME will offer you more freedom in the design and layout of your prefab steel structure building. In addition, you can add another section to the steel building if you need more space or disassemble it and move it.

FAQs About Prefab Steel Structure Warehouse Building

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.