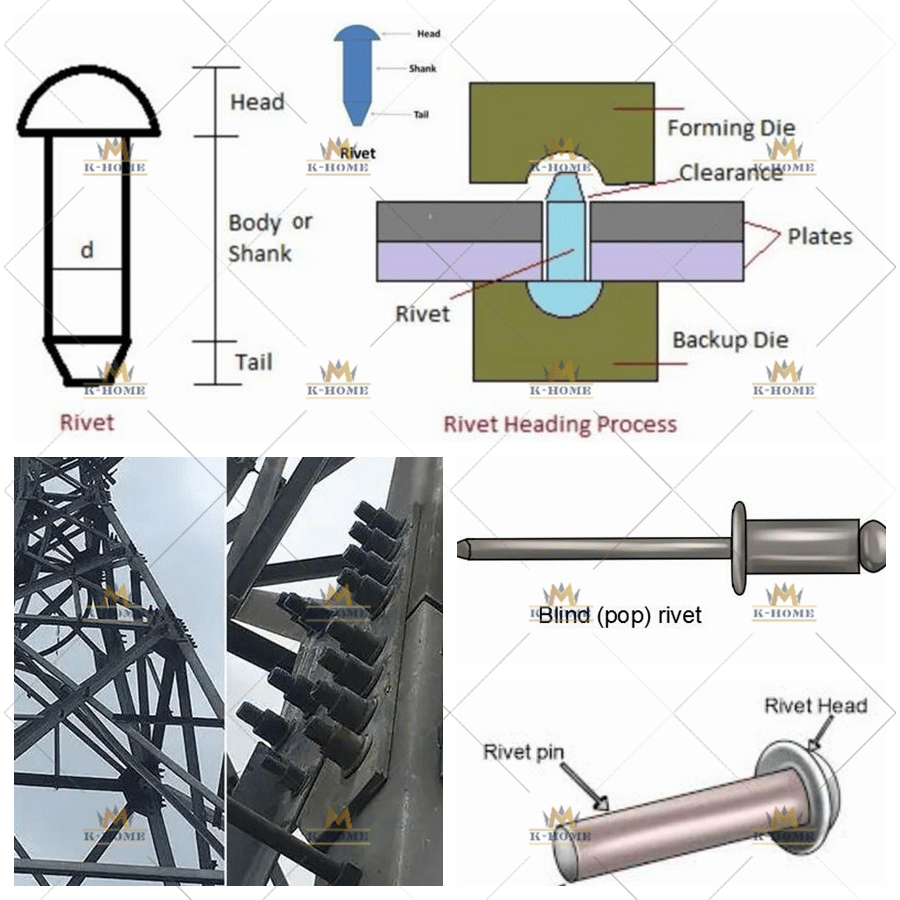

The rivets are generally classified as follows:

- Hot-driven rivets: The rivets which are driven in the hot conditions

- Shop rivets: The rivets which are placed in the workshop

- Field rivets: The rivets which are placed in the site/field.

Cold-driven rivets: Since high pressure is required to form the head at room temperature this type of rivet is limited.

Advantages: Reliable force transmission, good toughness and plasticity, easy quality inspection, good resistance to dynamic loads

Disadvantages: complex structure, expensive steel and labor

Although there are three connection methods for steel structure engineering, welding is the main method in the production process of structural parts. The quality of welded products is related to the quality of products used in the overall building. Therefore, welding must be fully welded, must not miss welding.

Further Reading: Steel Building Plans and Specifications

the Main Connection Methods

Steel structures can be divided into welded structures, bolted structures and riveted structures according to their connection methods. The main connection methods of the current steel structure are welding, bolting and rivet connection.

Welding

Welding connection is the most important connection method for steel structures at present, also known as welding, which mainly uses high temperature, heating or high pressure to combine metal technology. There are many welding methods, such as hand arc welding, submerged arc welding, tungsten TIG welding, gas metal arc welding, etc. What is actually used depends on the actual needs.

Advantages: simple structure, material saving, easy processing, and automatic operation can be adopted,

Disadvantages: High requirements for materials, welding will cause structural deformation and residual stress in the heat-affected zone, so in the welding process, it should be strengthened to prevent welding deformation defects and correct them in time.

Further Reading: Structural Steel Welding

Bolted Connection

Bolted connection is also a more common connection method, which is to use bolts to pass through the through-holes of the two parts to be connected, then put washers on, and tighten nuts. This method has the advantages of convenient and rapid assembly and can be used in structural installation connections and detachable structures.

The disadvantage is that the section of the component is weakened and easy to loosen. There are two types of bolted connections: ordinary bolted connections and high-strength bolted connections. The joint bearing capacity of high-strength bolts is higher than that of ordinary bolts, and high-strength bolt connections can reduce the weakening effect of nail holes on components, so they are widely used.

Among them, there are ordinary bolts and high-strength bolts. Ordinary bolts are generally made of ordinary carbon structural steel without heat treatment. High-strength bolts are generally made of high-quality carbon structural steel or alloy structural steel, which needs to be quenched and tempered to improve comprehensive mechanical properties.

High strength is divided into 8.8 grades, 10.9 grades, and 12.9 grades. From the strength grade: High-strength bolts are commonly used in two strength grades of 8.8S and 10.9S. Ordinary bolts generally have grades 4.4, 4.8, 5.6 and 8.8. High-strength bolts apply pre-tensioning force and transmit external force by friction, and ordinary bolts transmit shearing force by bolt rod shear resistance and hole wall bearing pressure.

Ordinary bolt connection

Advantages: easy loading and unloading, simple equipment

Disadvantages: When the bolt accuracy is low, it is not suitable for inspection. When the bolt accuracy is high, the processing and installation are complicated and the price is high.

High-strength bolt connection

Advantages: The friction type has small shear deformation and good elastic performance, especially suitable for structures with follow-up loads. The bearing capacity of the pressure-bearing type is higher than that of the friction type, and the connection is compact

Disadvantages: The friction surface is treated, the installation process is slightly complicated, and the cost is slightly higher; the shear deformation of the pressure-bearing connection is large, and it should not be used in structures that bear dynamic loads.

learn more about Types Of Connections In Steel Structures

Rivet connection

A non-removable static connection that uses rivets to connect two or more components (usually plates or profiles) together, referred to as riveting. Rivet connection has the characteristics of simple technology, reliable connection and non-removable type.

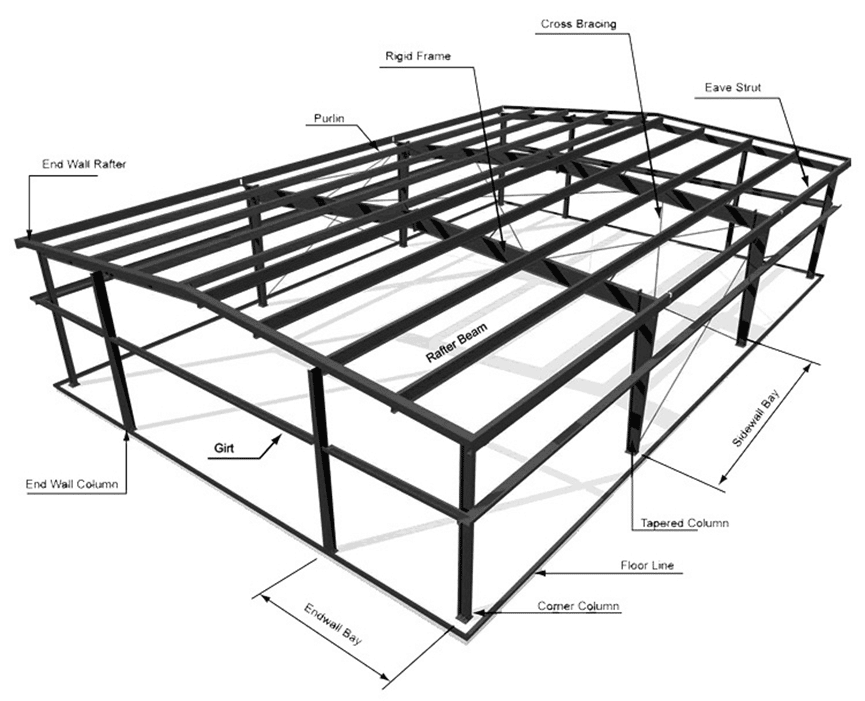

The PEB Steel Building

The Other Additional Attachments

Building FAQs

- How to Design Steel Building Components & Parts

- How Much Does a Steel Building Cost

- Pre-Construction Services

- What is a Steel Portal Framed Construction

- How to Read Structural Steel Drawings

Blogs Selected for You

- The Main Factors Affecting The Cost of Steel Structure Warehouse

- How Steel Buildings Help Reduce Environmental Impact

- How to Read Structural Steel Drawings

- Are Metal Buildings Cheaper Than Wood Buildings?

- Benefits of Metal Buildings For Agricultural Use

- Choosing the Right Location For Your Metal Building

- Making a Prefab Steel Church

- Passive Housing & Metal –Made for Each Other

- Uses for Metal Structures You May Not Have Known

- Why Do You Need a Prefabricated Home

- What Do You Need To Know Before Designing a Steel Structure Workshop?

- Why Should You Choose a Steel Frame Home Over a Wooden Frame Home

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.