Metal Building Windows

There are many types of windows for metal buildings on the market. K-Home offers a huge range of opportunities for updating the style of windows in metal buildings. They are an important part. And with your K-Home prefab steel structure, you may choose any style window that you would use in any other building.

Many steel structure housing suppliers only provide one kind of plastic steel window, which is very light in weight. This is the most common window on the market, but it is not suitable for all steel structure uses and environments, so in the later use process, there will be various Various problems that require a lot of time for secondary maintenance.

Why You Need Windows

Windows provide numerous benefits for any building, whether it’s a shed, barn, or garage in K-Home. Having windows can help improve a building’s air quality, which is especially important. Windows can also provide natural light to any structure. When the light enters your building, it lowers the need to use electricity for lighting.

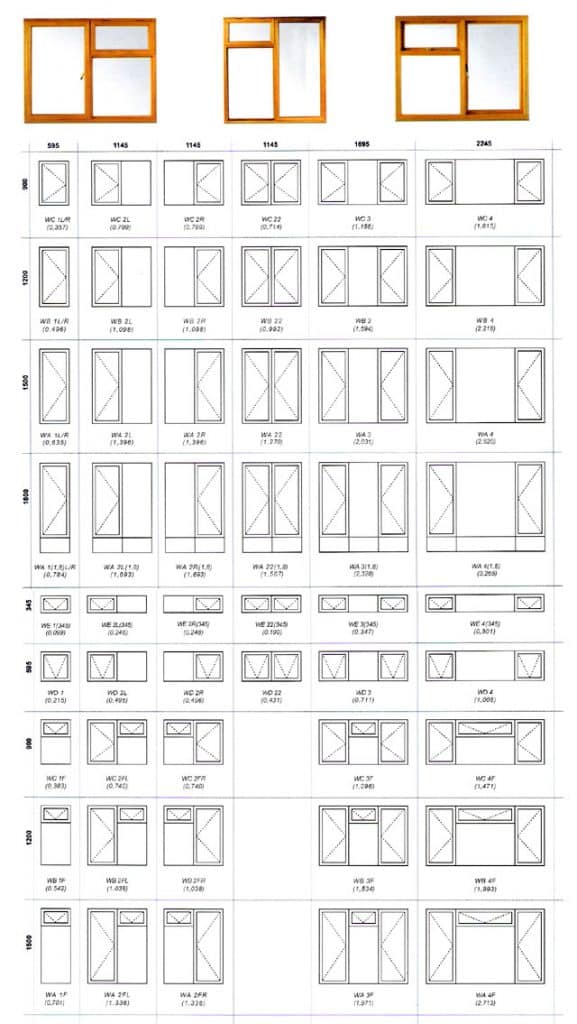

What size window do you need?

Design a warehouse with multiple windows. Think about the role of your window — not just now, but in the future. It can be used as exhaust shutters for toilets, transparent windows that require light transmission, sliding windows that require air replacement, etc.

In many commercial and industrial structures, K-Home will recommend the exact size and location of a window according to the total area and usage of steel frame building. Also, we’ll recommend different quality to meet various requirements.

The type of windows for metal buildings

K-Home Framing steel building windows come in wood, steel, aluminum alloy, PVC windows

1. Wooden Windows

Advantages of wooden windows:

- Durable and not deformed

- Good sealing effect, high energy saving and noise reduction

- Meet environmental protection requirements

Disadvantages of wooden windows:

- Poor installation quality

- Not moisture-proof, not fireproof, not corrosion-resistant, easy to damage

- Low security

Wooden windows are often used in holiday homes that require insulation and have a short lifespan

2. Stainless steel window

It has the properties of wear resistance, corrosion resistance and oxidation resistance, and the surface color is bright and bright. But because it is steel material, the quality is heavy, and it is inconvenient to disassemble and reinstall.

3. Aluminum Alloy windows

Light texture, strong plasticity, not easy to rust, long service life, and the price is not too high. However, because metal is a thermal conductor, it has high thermal conductivity and poor thermal insulation performance.

4. PVC windows

Small weight, good thermal insulation performance, relatively low price, very convenient installation. However, it is easy to deform and has poor fire and anti-theft properties. It is easy to change color and age after being exposed to the sun and rain.

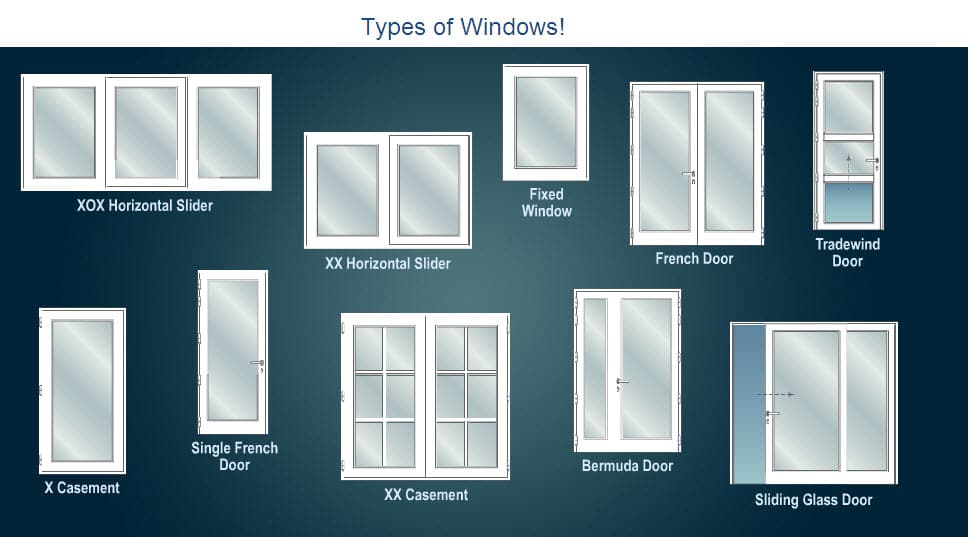

Different opening styles of windows

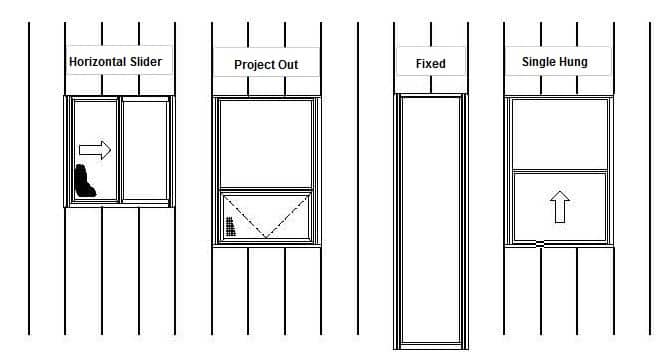

1. Casement windows

Casement windows are divided into two types: inward opening and outward opening. The biggest feature is that the window sash can be fully opened, the ventilation and sealing performance are good, and the structure is simple.

2. Sliding Windows

There are two types of sliding windows: left and right, up and down, with economical price and good sealing, but the ventilation area is limited to a certain extent.

3. Louver Windows

It is a special window used to block sunlight or block sight, with a fixed or movable shutter above it.

4. Fixed Windows

It cannot be opened, generally, there is no window sash, and the glass can only be embedded in the window frame, only for lighting and viewing purposes.

Tips on Choosing Windows for Metal Buildings

1. Material

The window frame of the window has a variety of materials, the most common are the aluminum alloy window frame and the plastic steel window frame, and the solid wood window is the most expensive.

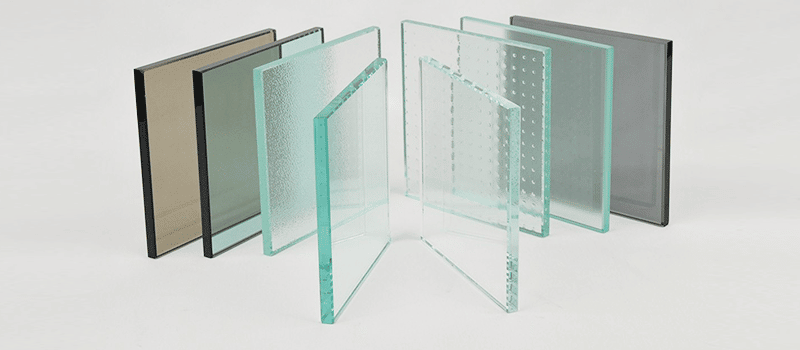

2. Glass

The selection of glass is generally from the following two aspects:

In terms of technology, it is divided into white glass, ultra-clear glass, coated glass, lowe glass, frosted glass, atomized glass, and insulating glass.

- White Glass: Ordinary transparent glass.

- Coated Glass: Coated glass is also called reflective glass. Coated glass is to coat one or more layers of metal, alloy or metal compound films on the surface of the glass to change the optical properties of the glass. The standard color is gray, blue, green, etc.

- Low-E Glass: UV-blocking, divided into high-transparency and low-transparency, high-transparency and white glass has the same visual effect, low-transparency means that both indoors and outdoors are a bit dark, but the lowe thermal insulation effect is not obvious.

- Frosted Glass: It is a translucent glass whose surface is rough and uneven by mechanical sandblasting, manual grinding (such as emery grinding) or chemical treatment (such as hydrofluoric acid dissolution) of ordinary flat glass. Often used for bathroom windows.

- Insulation Glass: Insulation glass has a special ability to absorb, transmit and reflect light and heat, and is used for exterior wall windows and glass curtain walls of buildings.

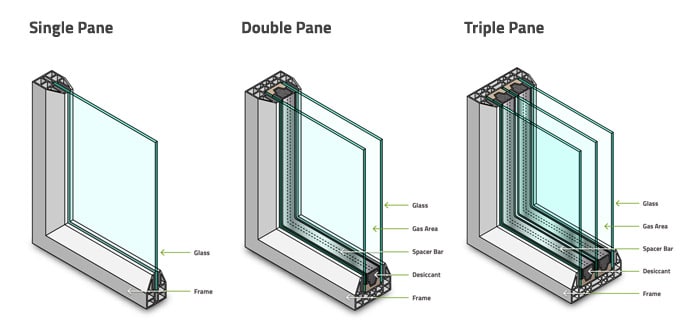

Specifications of multi-layer glass: laminated, double-layered hollow, three-layered hollow, and hollow laminated.

- Laminated glass: used in glass guardrails, sun roofs, and lighting roofs, it needs to bear weight. Even if it is broken, it can stick to another piece without falling and hurting people.

- Double-layer insulating glass: The vast majority of doors and windows are double-layer hollow, and the common ones are 12A 15A 18A 20A 27A. 18A and above are the best sound insulation.

- Three-layer insulating glass: hollow 12A/9A, three pieces of glass are two hollow, and the sound insulation effect is better than double-layer.

- Insulated laminated glass: The purpose is mainly for sound insulation. The hollow is generally 18A/20A. According to the data, 5+20A+5+6 has the best sound insulation effect. In particular, the sound insulation effect is good, and it is required near the railway station or airport.

3. Accessories

The quality of the accessories of the window will affect the sealing and opening and closing flexibility of the window, and also affect the service life of the window.

4. Workmanship

Whether there are scratches and undulations on the surface of the window frame; whether there are burrs or gaps in the corners; whether there is any abnormal sound when knocking on the surface, and products with good quality and sufficient materials generally have a thick sound.

Learn More About Residential Metal Garage Buildings

How to Install Window in Metal Building?

- Confirm the position of the window, our designer will communicate with you in advance the position of the window, such as the height from the ground, and the height from the ridge, and leave room for windows.

- After we confirm the installation location, we should start to check the size of the window and the size of the opening. If it doesn’t fit, try to modify it.

- Fix the window frame on the window beam, and punch holes here and at the fixing point, preset expansion bolts or plastic expansion pins to fix the window

- Seal, glue the seam between the window and the wall panel to avoid rain leakage.

Further Reading: Steel Structure Installation & Design

The PEB Steel Building

The Other Additional Attachments

Building FAQs

- How to Design Steel Building Components & Parts

- How Much Does a Steel Building Cost

- Pre-Construction Services

- What is a Steel Portal Framed Construction

- How to Read Structural Steel Drawings

Blogs Selected for You

- The Main Factors Affecting The Cost of Steel Structure Warehouse

- How Steel Buildings Help Reduce Environmental Impact

- How to Read Structural Steel Drawings

- Are Metal Buildings Cheaper Than Wood Buildings?

- Benefits of Metal Buildings For Agricultural Use

- Choosing the Right Location For Your Metal Building

- Making a Prefab Steel Church

- Passive Housing & Metal –Made for Each Other

- Uses for Metal Structures You May Not Have Known

- Why Do You Need a Prefabricated Home

- What Do You Need To Know Before Designing a Steel Structure Workshop?

- Why Should You Choose a Steel Frame Home Over a Wooden Frame Home

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.