What Is The Enclosure System Of The Steel Factory Buildings?

No matter what kind of building it is, during the construction process, a weighing skeleton that supports the entire building mass is required. Steel structure buildings use steel as the mainframe. They are made of steel beams, steel columns, steel trusses, and other components from section steel and steel plates. The components are usually connected by welds, bolts, or rivets. The maintenance system of the roof and wall usually adopts a single tile or sandwich panel, and the roof can also use the lighting panel to make the interior brighter.

Further Reading: Steel Structure Installation & Design

Steel Factory Buildings have the characteristics of high strength and low quality and can build some structural buildings with large spans and large loads. This is not available in some concrete structures and brick-concrete structures, so it can effectively reduce the construction cost and shorten the construction period during its use.

Since geological activities have entered a relatively active period, solving the problem of building earthquake resistance is a hot issue in the current construction industry. PEB steel mental buildings have good seismic performance because steel has good elasticity and toughness within the stress range and will not break due to a sudden increase in weight.

With the rapid development of my country’s economy, there are more and more large-span and high-standard construction projects, especially large-scale factories. These projects not only have high quality requirements and short construction periods but also have high requirements on the space utilization rate of buildings, which is difficult for traditional architectural forms to meet. Therefore, more and more people choose Steel Factory Buildings.

Main types of Steel Structure Workshop Enclosure:

Metal Cladding System

The roof of the steel structure buildings is commonly used in beam-column structures such as solid-web type steel, lattice type, box type, etc., as well as around pipes, round steel, angle steel, etc. as connection and support systems. PL means flat plate, round tube D means diameter, casing CG is conventionally made of round tube, purlin T and QLT are commonly used C-shaped steel, Z-shaped steel or high-frequency welded steel, and bracing ZLT and XLT are commonly used with round steel at both ends. Threads are fastened and connected with nuts, and angle steel is also used. Corner brace YC is commonly used angle steel, tie rod XG is commonly made of round pipe, and it is also made of profile steel. Round steel or angle steel is commonly used for column support ZC and roof support SC. Maintenance materials usually use color steel tiles, sandwich panels, lighting tiles, etc.

Due to the unsatisfactory lighting effect on the roof of the traditional reinforced concrete structure workshop, a large number of lighting windows are usually designed in the design, and a large number of lighting windows will destroy the line shape of the wall, but the Steel Structure Workshop will not be troubled by this.

The light steel structure roof uses a large number of roof lighting panels, which not only provides uniform lighting but also do not damage the line shape of the wall. It is both practical and beautiful. At present, it is very suitable for combined Steel Structure Workshops.

Prefab Steel Structure Workshop: Design, Type, Cost

Load-Bearing Wall

The wall of Steel Structure Workshops is mainly composed of wall frame column, wall top beam, wall bottom beam, wall support, wallboard, and connector. Steel Structure Workshops generally take the inner transverse wall as the load-bearing wall of the structure, and the wall column is a C-shaped light steel component.

Its wall thickness is usually 0.84 ~ 2mm according to the load, and the spacing between wall columns is generally 400 ~ 600mm. Steel Structure Workshops can effectively bear and reliably transmit the vertical load, and the layout is convenient.

Force System Of Steel Structure Workshop

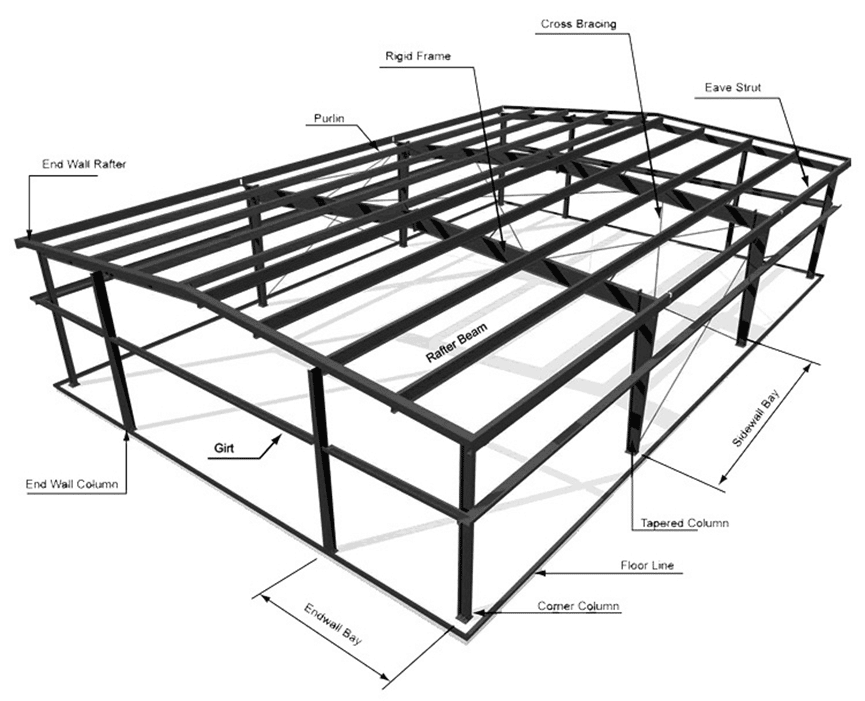

The components of the steel structure workshop mainly include a support system, envelope structure system, frame structure system, roof structure system, etc.

In order to ensure a normal and safe production environment in the factory building, the enclosure structure system forms a wind load that bears and transmits the weight of the enclosure wall through foundation beams, wall beams, exterior walls, and wind-resistant columns. The wind load acts on the wall.

The frame structure system is composed of horizontal and vertical frames. As the basic load-bearing structure of the steel structure workshop, the horizontal frame is of great significance, which is composed of a foundation, roof truss and horizontal columns. When constructing the connection between the roof beam and column top, a rigid connection or hinged connection can be used.

Most of the connection between the column and the foundation can only be in the form of a rigid connection. The components of the longitudinal frame are much more complicated than those of the horizontal frame.

Its components include longitudinal columns, foundations, connecting beams, inter-column supports, brackets, crane beams, etc., which mainly bear longitudinal wind loads, Longitudinal temperature stress, longitudinal seismic force and longitudinal horizontal braking force of the crane, etc. It is also essential for the role of the steel structure workshop.

The roof structure system includes everything needed for a steel plant roof, such as roof panels, roof supports, gutter panels, brackets, purlins, roof beams, and more.

Horizontal Frame Load Of Steel Structure Workshop

According to the conventional calculation method, the design of the steel structure workshop should take the overall spatial structure built by the horizontal frame and the longitudinal frame as the calculation object, but this calculation method is more complicated and the workload is extremely large, so in the actual calculation work Usually, the load borne by the horizontal frame and the load borne by the longitudinal frame are calculated separately. The workload of this calculation method is relatively small, and the results obtained are also in line with the actual data.

The horizontal frameworks

The horizontal frameworks in the steel structure workshop: bear all the lateral and longitudinal loads inside the workshop, determines the basic unit of the steel structure workshop through the horizontal frame design, and then pass through various components such as crane beams. Connect the horizontal frame to make it a three-dimensional space structure, so as to ensure that the longitudinal rigidity of the workshop skeleton meets the load-bearing requirements of the steel structure workshop.

In the design method of the transverse frame of the steel structure workshop, the load calculation for the transverse frame only includes the bearing capacity of the transverse plane, and the longitudinal wind load is not considered.

However, in actual work, the longitudinal wind load is only considered in the design of the longitudinal bracing, but in fact, when the frame of the transverse structure is subjected to the transverse wind load; the longitudinal wind load will also affect it. Therefore, the out-of-plane bending moment caused by the longitudinal wind load should also be added to the horizontal frame design of the steel structure workshop.

Further Reading: Steel Building Plans and Specifications

The PEB Steel Building

The Other Additional Attachments

Building FAQs

- How to Design Steel Building Components & Parts

- How Much Does a Steel Building Cost

- Pre-Construction Services

- What is a Steel Portal Framed Construction

- How to Read Structural Steel Drawings

Blogs Selected for You

- The Main Factors Affecting The Cost of Steel Structure Warehouse

- How Steel Buildings Help Reduce Environmental Impact

- How to Read Structural Steel Drawings

- Are Metal Buildings Cheaper Than Wood Buildings?

- Benefits of Metal Buildings For Agricultural Use

- Choosing the Right Location For Your Metal Building

- Making a Prefab Steel Church

- Passive Housing & Metal –Made for Each Other

- Uses for Metal Structures You May Not Have Known

- Why Do You Need a Prefabricated Home

- What Do You Need To Know Before Designing a Steel Structure Workshop?

- Why Should You Choose a Steel Frame Home Over a Wooden Frame Home

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.