These days, increasingly, more people are all ears to their influence on the environment as energy prices rise. These features play an enormous role in steel buildings becoming progressively more all the rage. In addition, metal buildings are much more maintainable and ecologically aware than brick and wood constructions. Here are some ways that steel buildings help decrease environmental impact:

Recyclable

Steel is wholly eco-friendly and has the remarkable ability to be reused time and again. If you look around your home or commerce, some of the steel used in objects or structures nearby you might have been initially produced a long time back. Steel does not lose power when being reused, which means that when a steel building is demolished, it’ll be salvaged and reclaimed. In addition, reusing steel helps to reduce the quantity of iron that needs to be excavated. This decreases the time and resources necessitated to handle and fabricate articles.

Sustainable

When you choose to go with a steel building more willingly than a wooden structure, you select a much more ecological material. It takes more than 20 years for trees to grow substitutes that are large enough to be garnered again. As soon as a wooden structure is broken off, its materials cannot be recycled. Steel, as we stated, is recyclable and is typically made of previously recycled steel. Milling steel needs minimal amounts of water. Milling steel likewise necessitates less energy, and steel recycling plants are present in large numbers. This helps decrease transportation spaces to transport the steel to construction sites. Correspondingly, since steel has a much higher strength to weight proportion, it takes fewer materials to create a steel building than a wood-framed structure.

Waste Lessening

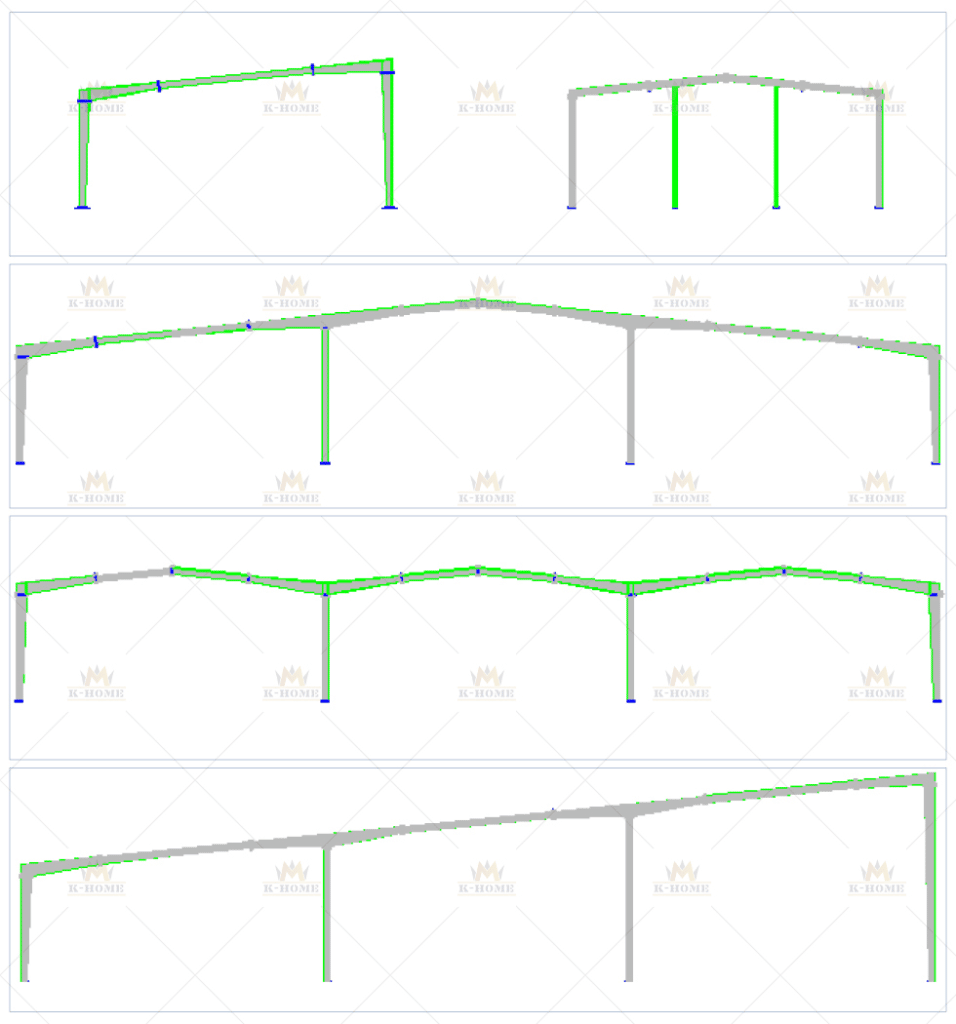

Prefabricated steel buildings usually necessitate shorter construction times and much less construction surplus than all additional types of building resources. The creation process is speedy and straightforward since the steel building components are incised to precise length and pre-punched before arriving on the site. Nevertheless, there will be a tiny amount of material waste to spare on construction place after a steel building is finished. But wood buildings need material to be cut on the location, and because of this, you’ll see a considerable amount of leftover being outstanding.

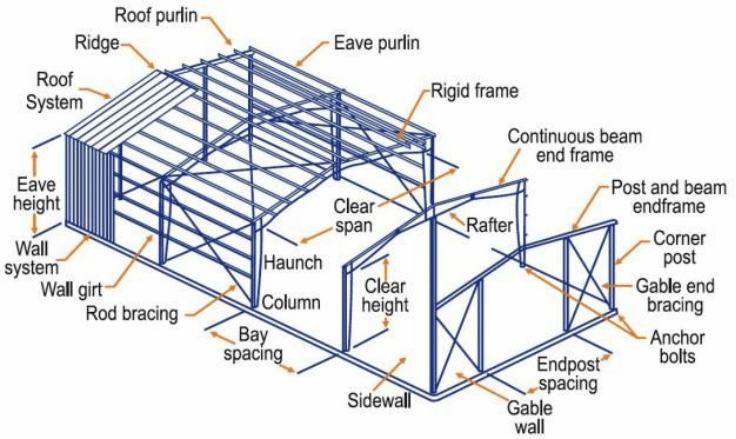

Further Reading(Steel Structure)

Energy Savings

Steel buildings help decrease the aggregate of energy used to cool or warm the building. Solar energy mirrors off the steel material and makes the building chiller. You can also insulate a steel building without difficulty, which would help decrease the requirement for additional energy usage. Insulation helps keep the cold air out throughout cooler months and helps keep the interior of the building chiller during the hotter times.

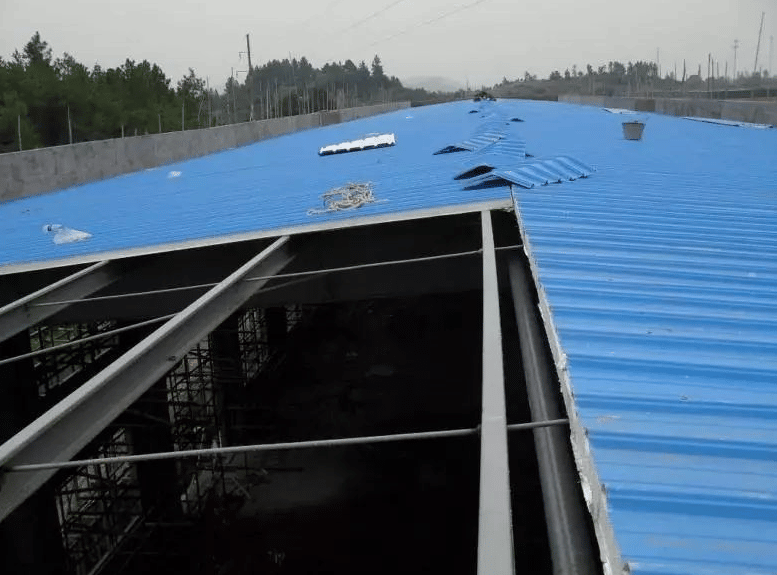

Fewer “Heat Island” Problems

If you’ve ever been on a tennis court and then on a huge parking lot, you’ve perhaps detected that the heat flaking the parking lot is not coming off the court. Concrete can make a giant “heat island” that doesn’t permit solar energy to spurt effortlessly. Reflective materials are the most acceptable way forward. Well-lit steel roofs can reflect maximum solar energy into the air, which helps decrease some heat island consequences.

Lower Upkeep Charges

Steel buildings are tremendously durable. This helps decrease any upkeep and restorations that you might require. There is no requirement for fresh coats of paint each year, and the HVAC equipment shouldn’t be functioning as intense, so it’ll collapse less frequently. Steel buildings are the most sustainable since they necessitate the smallest amount of preservation or repairs.

Resilience

Again, steel buildings are rigid. They last incessantly and save people cash on the upkeep and minor repairs. When natural disasters hit, metal structures are continuously the ultimate buildings still erect or the least probable to end up smashed and need maintenances. Other materials aren’t just additional expensive long term, but purchasing fresh materials constantly isn’t very workable.

Cooler Coatings

The use of cool coatings is one more way that steel buildings are helpful to the environment. These coatings are complemented to the outside of steel buildings and bring about more than a few environmental paybacks. Cool coatings will upsurge the reflective value of the building, which means the necessity for air conditioning in the summertime months is decreased. The reflective quality of the rooftop likewise decreases a spectacle known as an ‘urban heat island’. With conventionally constructed buildings, heat is deposited in the roof surface as the sun shines bright on it the entire day. At night, that heat is emitted back up into the air. In thickly populated areas, all that heat receding into the air at night means that the temperatures can’t get as little as they generally would. This adds to global warming and is diminished with steel buildings since the heat is returned up throughout the day.

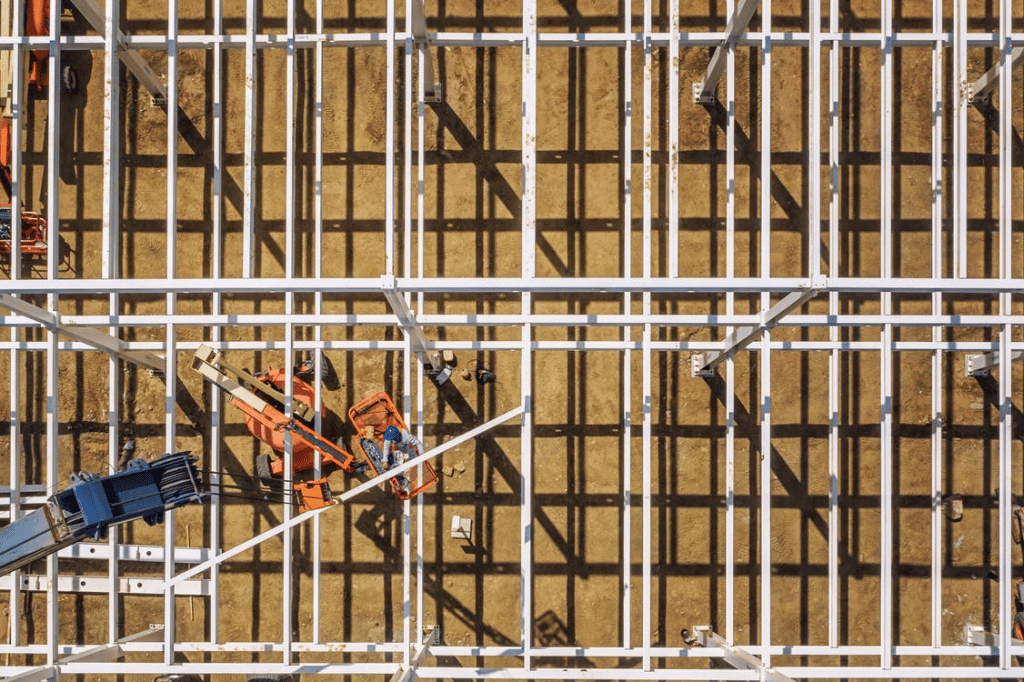

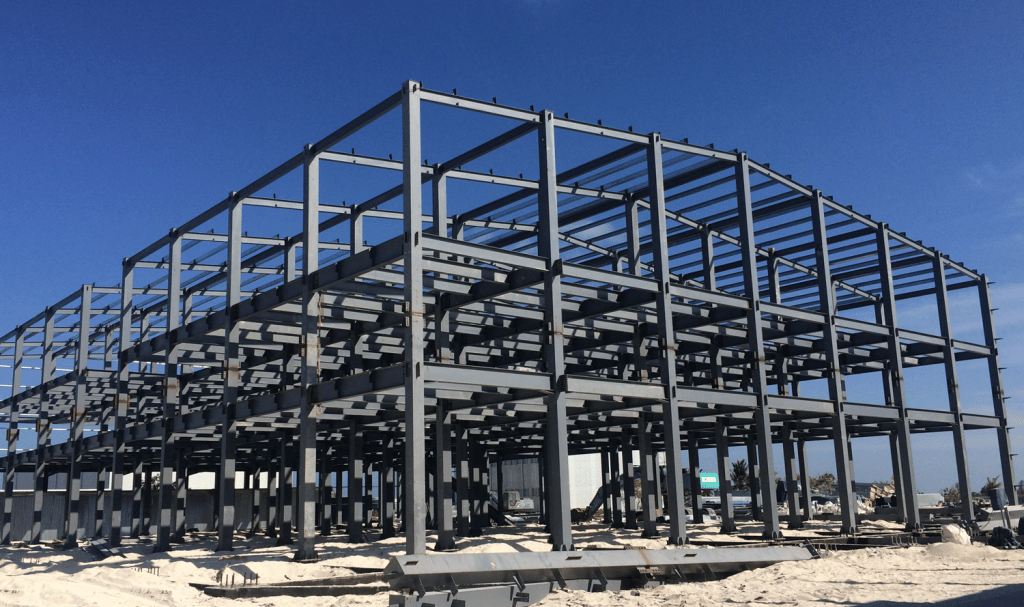

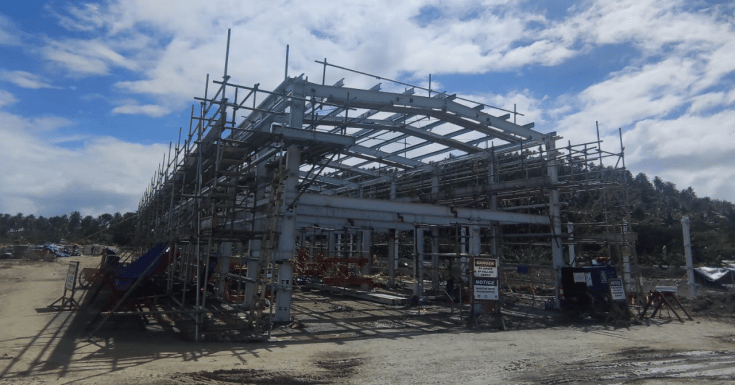

Swiftness of Construction

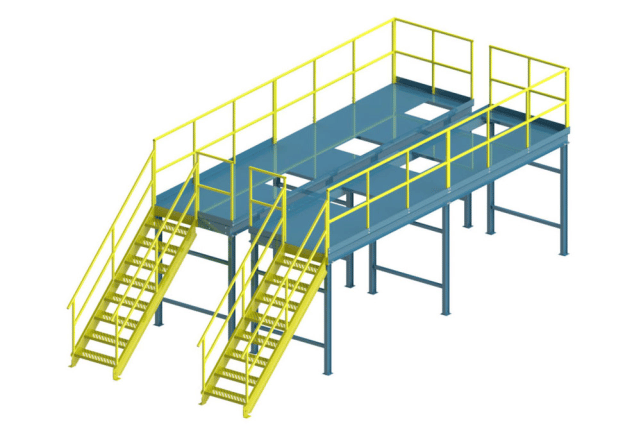

A pre-engineered steel building is slenderer in weight than concrete or wood, making the creation more easily controlled. Steel structures also necessitate less space than similar models consisting of concrete, stonework or timber. Manufacturers typically make steel buildings using prefabricated panel inserts comprising an insulating foam coating.

Construction workers rapidly syndicate these panels utilizing the different designs created on the boards. All of these elements are likewise biodegradable products. The comfort of uniting panels also offers the chance of extending or lessening building size if essential. Notwithstanding the design and flair of a building, builders have the competence of creating steel rendering to requirements.

Additional Energy Saving with Solar

If saving energy from your home’s more excellent insulation wasn’t sufficient, be watchful that steel frame homes are astonishingly strong and can base solar panels without difficulty. Solar panels add worth to your home while plummeting your energy bill since you make your own! A characteristic return on asset for a solar panel is 15-20%, and the investment continues to cultivate as energy becomes increasingly overpriced. Not to mention the sense of safety distinguishing that your home will be able to maintain these panels for the foreseeable future.

Recommended Reading

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.