When you construct a prefabricated house, you gain countless advantages. People used to think that prefabricated homes were made of cardboard. But that thought has long been entrusted to the times gone by. At present, a prefabricated house can effortlessly compete with a usually concrete place. Here is why a prefabricated house is all the rage:

Prefab homes provide rapid, reasonable housing

Luckily, in the past few years, more of these prefabricated housing projects have arisen (occasionally apparently instantaneously!) in the city to offer a home for more helpless inhabitants. These micro-apartments and prefabricated buildings offer a fast and eye-catching way of tackling the housing emergency in significant towns. And throughout the pandemic, housing people in their unique space instead of jam-packed shelters has been unquestionably indispensable to decreasing the risk of people getting ill.

Learn More About Residential Metal Garage Buildings

Prefab homes can be impressive ‘laneway’ homes

Prefabricated, sectional homes and tiny homes are progressively popular as a method to add on a present home. This is magnificent for housing in-laws or adult offspring in a discrete space, letting a helpless relative or acquaintance live self-sufficiently but with backing close by, or merely as a loan helper or asset in your property.

Prefab homes propose significant cost savings!

Prefabricated homes have a rapid turnaround cheer to well-organized design and structure developments. This helps keep both raw material and labor charges low, saving you money. Perhaps you’ve been looking into land or a newfangled build on the current property, and the asking price of conformist construction baffled you. You can talk to prefab home companies for an approximation of your project.

It’s difficult to assert an average price to construct a detached home, but one thing is definite: conventional construction takes lengthier and poses more chances for things to go askew and get excruciatingly costly.

Learn More About Influences the Price/Cost of Steel Building

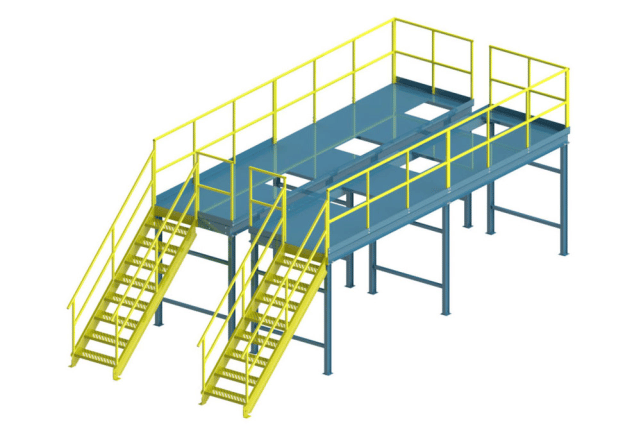

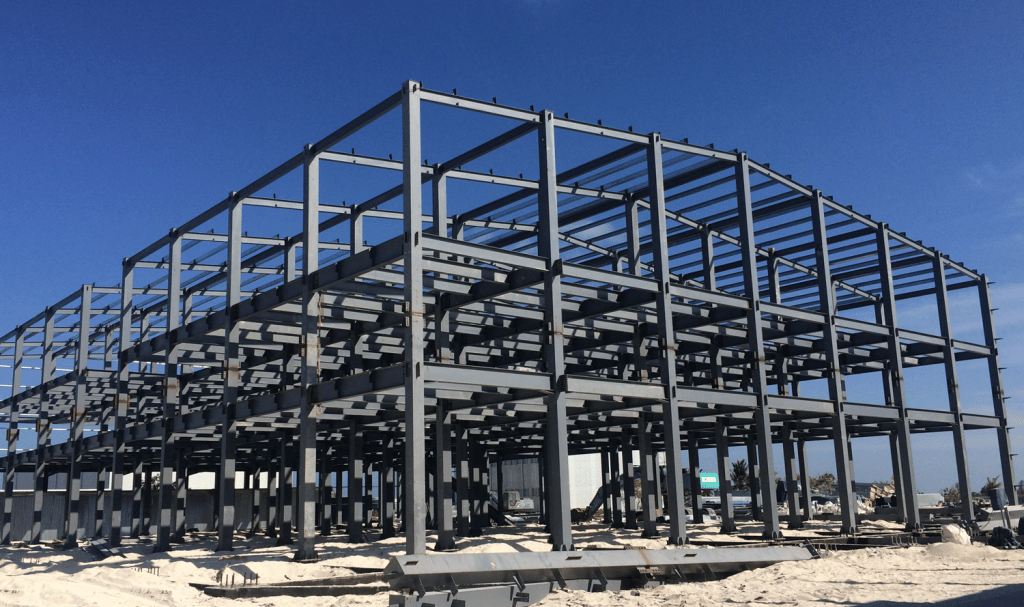

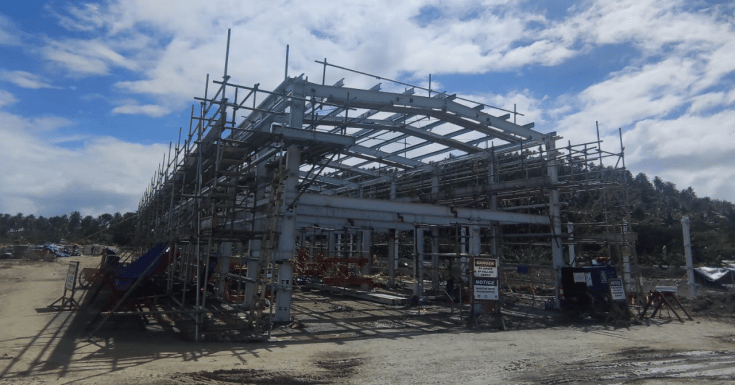

Efficient construction on-site means more minor things can err

A prefabricated home is constructed off-site in a workshop and transported in pieces to a building site where it is rapidly drawn together in place. Since these homes often abide by a set design pattern for the maximum part, the on-site team classically faces a small number of obstacles in putting the house in place.

However, unlike usual construction, this can mean an effortless timeline, with additional services such as sanitation and wiring easily arranged at the correct time and with no postponements.

A prefabricated home might only take a few days, weeks or months from preliminary design to moving in. Indeed, it can take as extended to organize a conventional building site for the building procedure as it can to construct a whole prefabricated home.

This is partly because shaping and creating prefab pieces inside eliminates the possibility of postponements due to weather conditions. According to research, the maximum number of prefabricated homes is completed in about five months. However, some might take just a few months, and tinier homes might take even lesser.

Associate that to building times of equal to three years for some house projects in certain cities, or nearly 18 months for a usually built separate family home! Thus, it’s easy to see the desirability of a prefabricated home, particularly for the young generation trying to get into the housing marketplace for the primary time.

Prefab homes are more hard-wearing than a house built on the location

Tiny homes are well-thought-out to be mobile homes, which means they do not have to be constructed. The same is not factual for prefab homes, which are frequently more resilient than usual homes as they have to withstand the severities of the drive to the site! And, since most of the work is completed off-site in a weather-resistant workshop, impairment from rain, animal harm, and additional factors is much less complicated. This means scarcer revolting shocks after you move in.

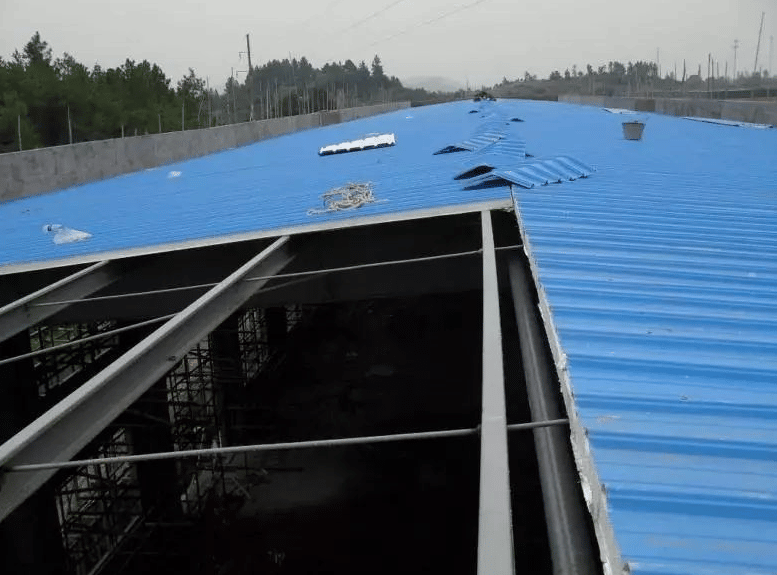

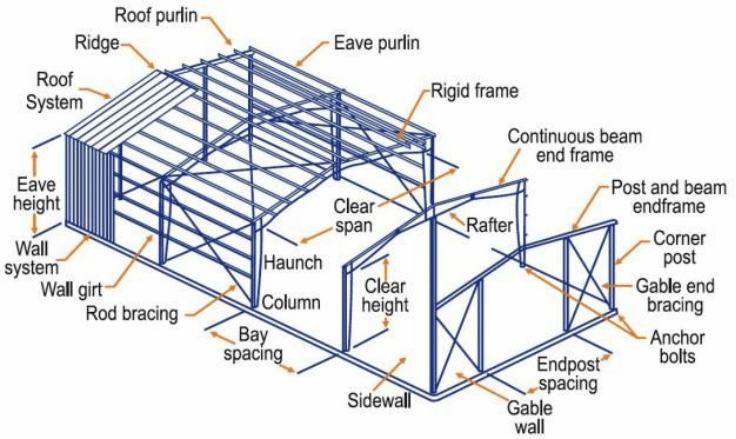

Steel Cladding System

Prefab homes can utilize native materials in large quantities.

A prefabricated home can habitually be made employing materials available locally, with prefab building companies knowing well beforehand how much of apiece material they’ll require. This generates the chance for better local sourcing and bulk reductions, making things inexpensive for you and healthier for the environment as transportation discharges are decreased.

Prefab homes may have lesser permit fees and smooth progressions

If you’ve ever been vexed to get planning support and licenses for a new construction project, you’ll know what a menace it can be. Prefab homes frequently have a lesser ‘permit value’ and quicker, pre-cleared permit procedures. And your prefab construction business is expected to know how to make this procedure go effortlessly and speedily.

Prefab homes can be very ecological

Prefabricated homes can be tremendously fashionable and, if you select the right company, very ecologically equated to a usually built home. Along with the possible benefits of using locally sourced resources and buildings, prefab homes are often intended to include passive heating and cooling systems and other energy-saving processes. And, once more, since the companies building these homes make more than a few identical types every year, they have a lot of knowledge on the most delicate systems for every design.

Additionally, panelized and segmental construction in the workshop can mean that prefab homes have close-fitting air seals, assisting in reduced energy seepage and making for a more environmentally and comfy home.

And in conclusion, because the manufacturers don’t have to worry about acquaintance with the weather throughout the construction of interior materials, they might be able to sidestep the usage of weather-shielding substances and coverings that can make an on-site building more poisonous to the environment.

Conclusion

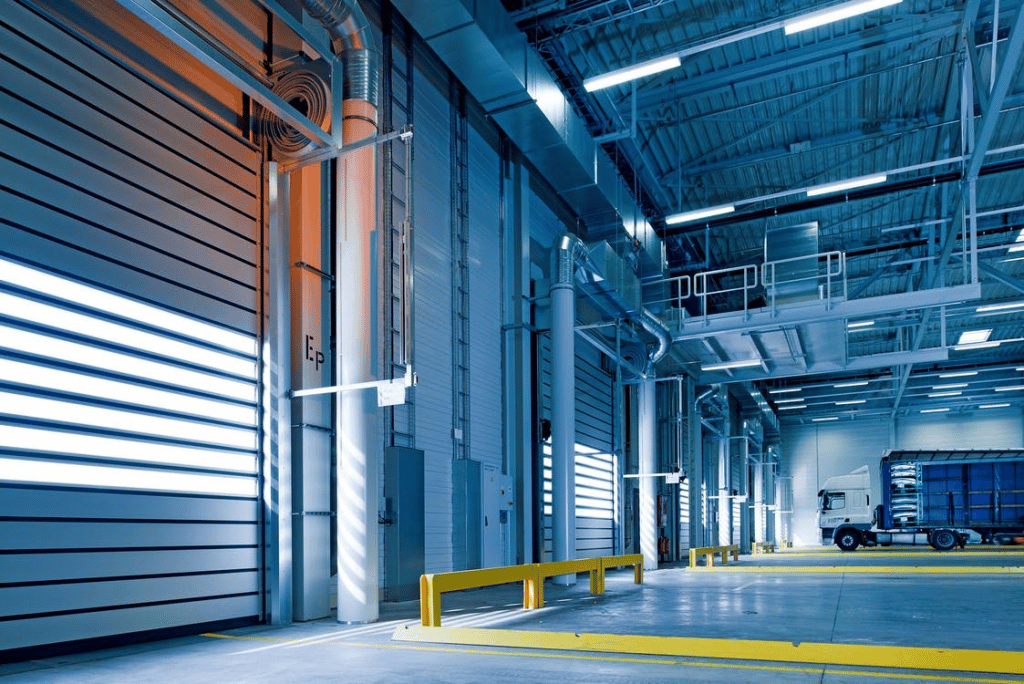

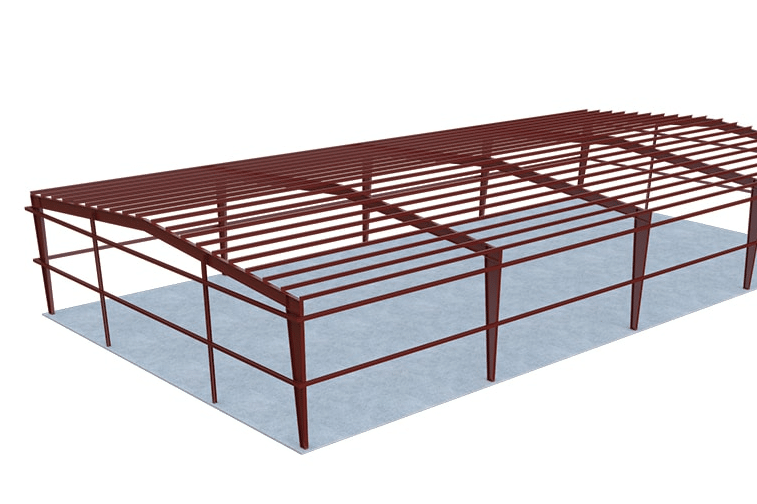

Prefabricated homes that use segmental, factory-made, and panelized methods make up more than a quarter of building in the United States. Not only will you make it great for the environment, but you get to have a comfortable and lovely home, just the way you like it! K-home serves pre-engineered manufacturing, agricultural, commercial structures. No matter where you are in building development, K-home will deliver the most satisfactory solution for you.

Recommended Reading

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.