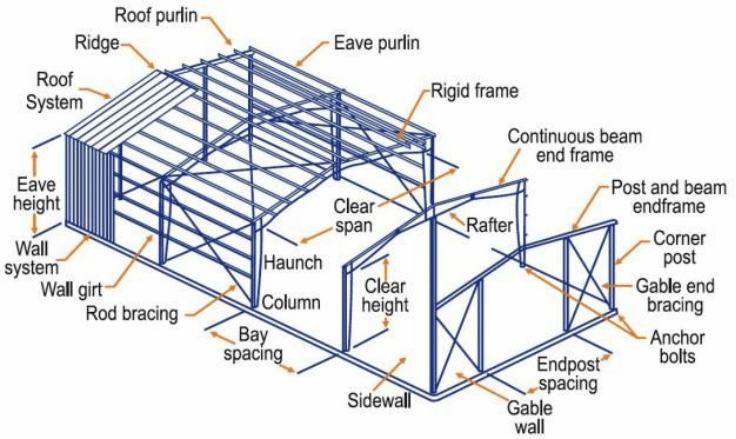

Have you ever wondered what you would look like if you didn’t have a skeleton? A skeleton is under all the skin and muscle that keeps everything in sync. The same pertains to a house where the frame functions as the skeleton.

It can be a wooden or steel frame home contingent on your partialities. These building selections have their advantages and disadvantages, but they both deliver a robust building frame for your house. In addition, you can get an effortless finish on your home frame with the most delicate drill bits for steel!

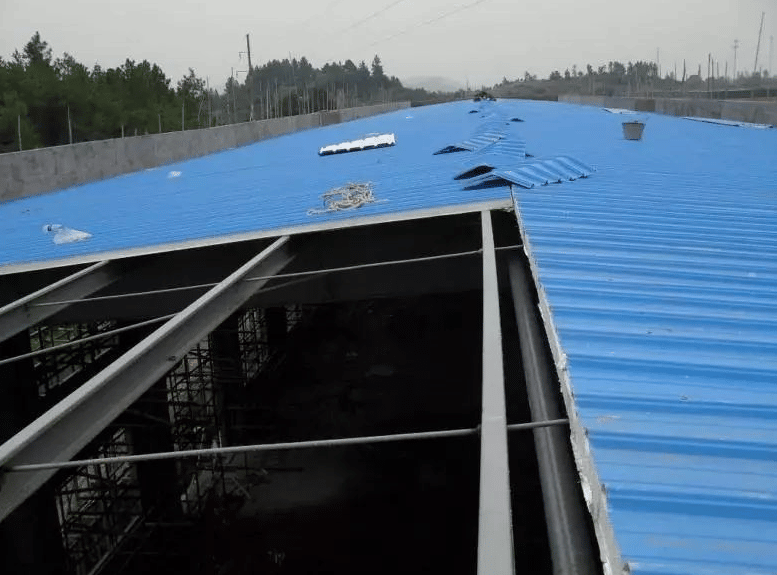

Timber frame homes are considered old-school, while steel frame homes are sturdier, long-lasting, and safe from annoying termites! Thanks to this, more constructors are choosing to utilize steel frames throughout construction.

Learn More About Residential Metal Garage Buildings

Why Should You Select a Steel Frame Home over a Wooden Frame Home?

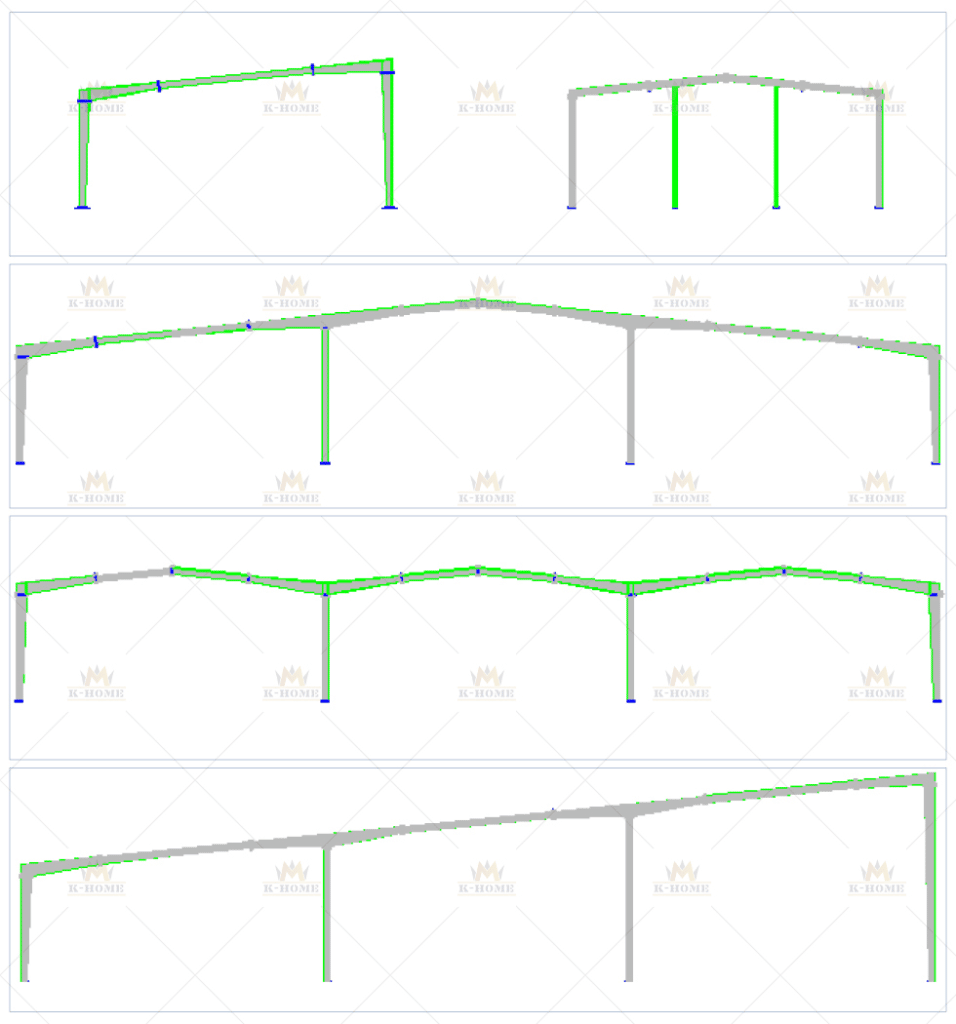

Thanks to technical progressions and increased use of framed construction, building times have been reduced. More manufacturers are deciding to use framed structures contrasting to the characteristic brick homes. Here are some of the main reasons:

High Resistance

Associated with wood frames, steel frames have more excellent resistance to dilapidation. For instance, if you associate a wooden floor with and steel floor, you are expected to observe damage on the wooden floor as the floor withers. The equivalent relates to pests, for example, termites. Pests can dig into timber but not into steel. As the termite invasions are extremely improbable on steel frames, the budget for handling the frames is suggestively lesser.

Correspondingly, in the circumstance of a fire abolishing your home, the steel frame will be left upright. Nevertheless, the fire will terminate the wooden frames.

Environmentally Responsible

While steel is not the most environmentally friendly building material, it has the potential that make it ecologically accountable. Let’s say you can reprocess steel which means it has a lengthier life cycle. Steel is possibly the most reprocessed material universally.

How Steel Buildings Help Reduce Environmental Impact

Furthermore, utilizing steel frames means less deforestation since timber is gathered from wood—the lesser the necessity for timber, the lesser the requirement to put an end to forests. Not like wood frames, steel frames are factory-made with accuracy, thus less waste. Wood, conversely, has natural limitations, which makes part of it inoperative.

Cost-Effective

In its regular state, wood is more economical than steel, but the entire cost after setting up might be identical. This is since steel frames are constructed offsite, conferring to the set stipulations. Pre-fabrication decreases wastage and increases competencies.

Correspondingly, steel frames work better than wood frames, add worth to your estate, and the quality is faultless. All these features make it a lucrative building solution. In terms of construction charges, much of the savings will be in budget and labor welfare of lessened construction time. Additional areas you will save comprise landfill charges and upkeep payments.

As steel is mass-produced, there is less expenditure, and any of the unwanted can be reprocessed. Furthermore, its endurance to degradation transforms into negligible repair and upkeep dues. Last of all, the progression in manufacturing technology has reduced the cost of manufacturing steel.

Learn More About Influences the Price/Cost of Steel Building

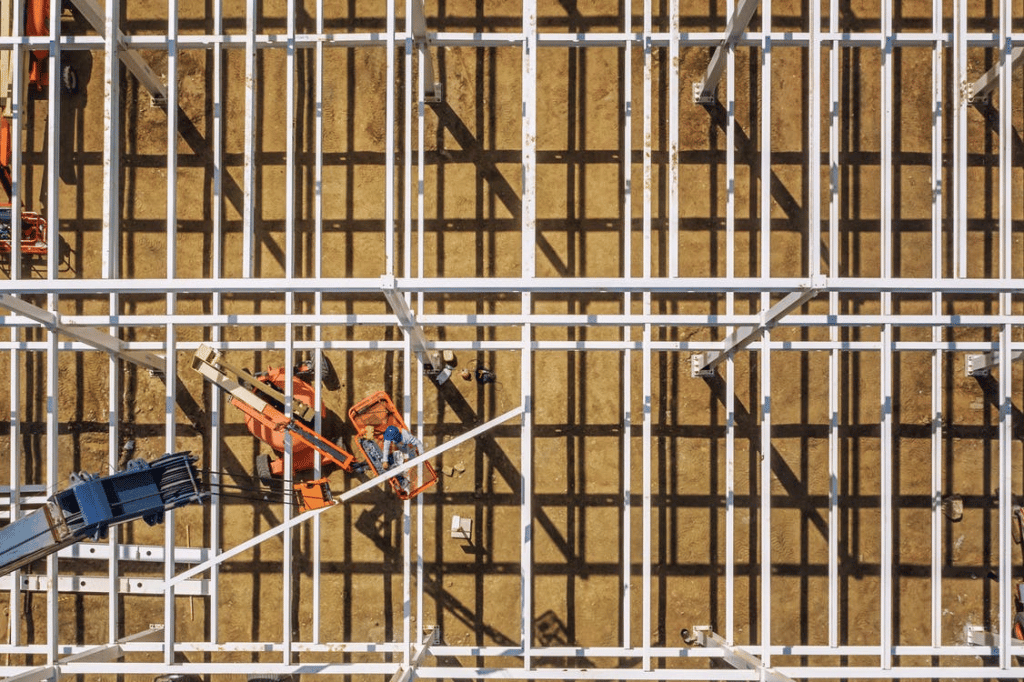

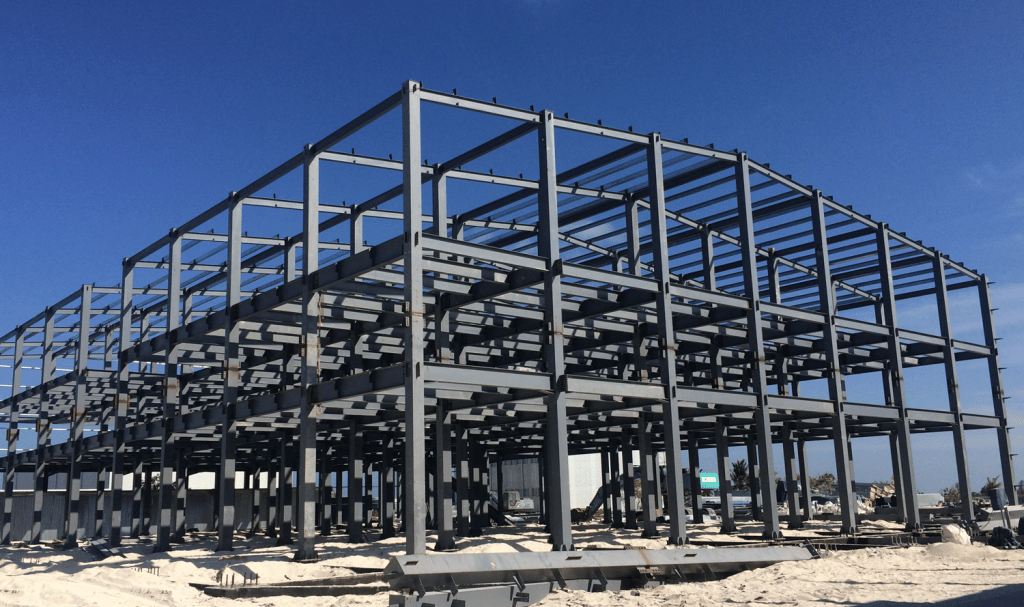

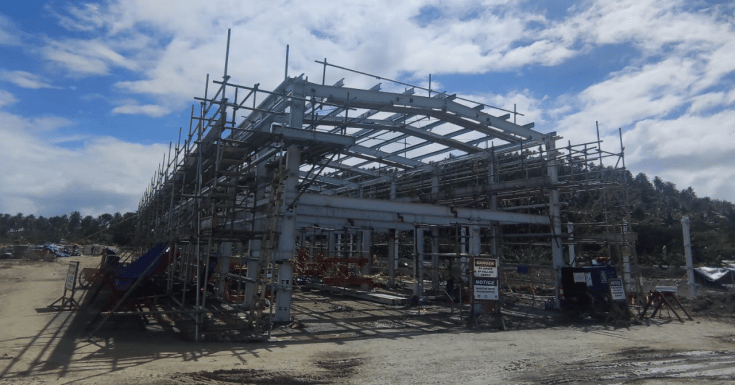

Faster Construction Time

As the saying goes, time is money. The quicker you build, the lesser the cost of building. Finalizing a construction project punctually or ahead of the agenda means you don’t have to struggle with the price for the additional days. Each additional day the project is overdue will cost you cash. All of this can be circumvented by utilizing steel frames.

Accelerated projects are often a nuisance for building squads and designers. This is since they have to make shortcuts to provide on the due date. Steel frames make it stress-free to meet set deadlines without any hanky-panky.

To begin with, steel is pre-made to the precise designs provided. The frames are then transported to the construction site and instituted. This will not simply accelerate construction time but likewise, decrease labor expenditures.

Steel is lighter than wood.

When you equate a steel frame to a wood frame, you will be astonished to see that the steel frame is lighter. This is credited to the scheme of the frames. The lighter weight is pretty useful as it decreases shipping and construction charges.

Further Reading(Steel Structure)

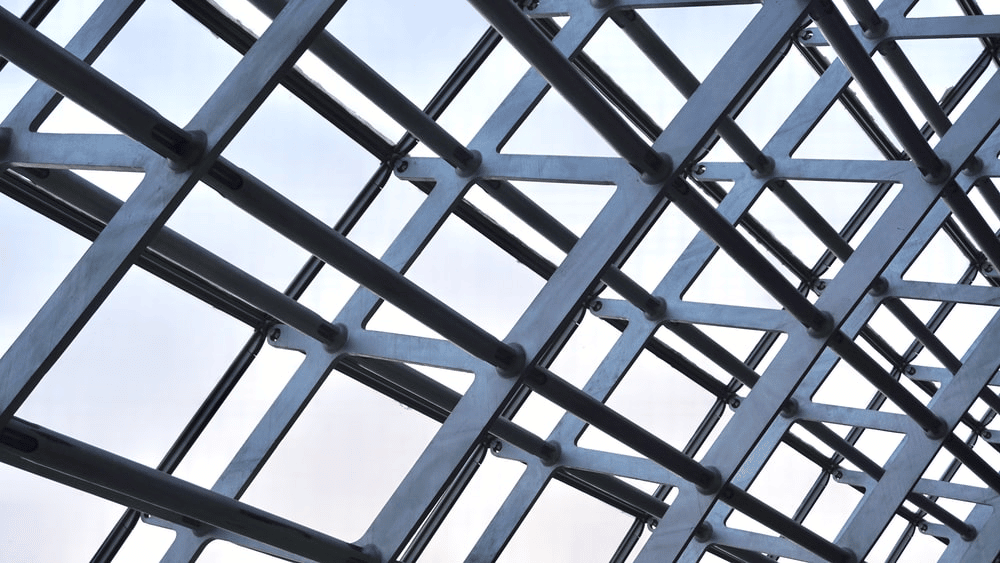

Aesthetics

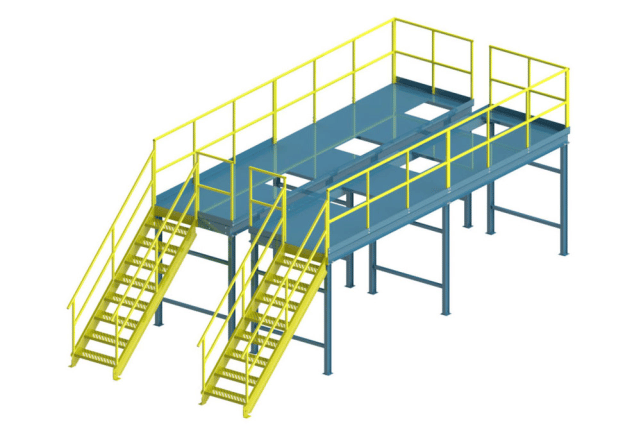

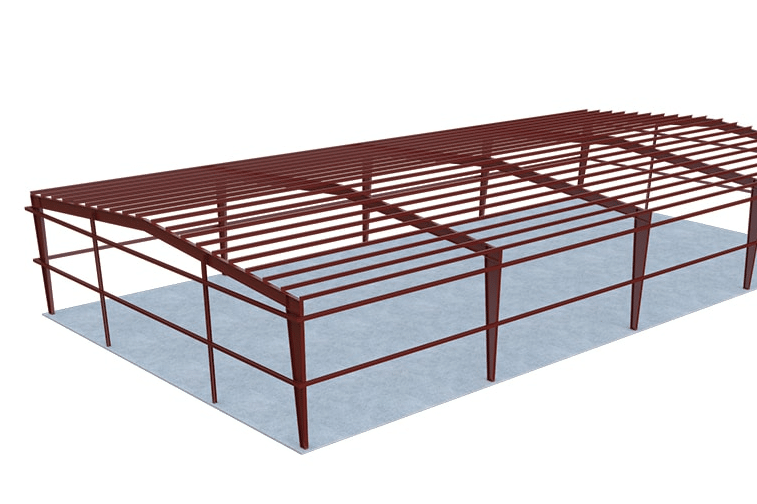

Developments in technology have made it conceivable to think of innumerable designs. This allows designers the liberty to experiment with the design to create an artistically attractive home. Moreover, steel is sturdier than wood, making it easier to make enormous open-plan designs that were formerly not imaginable with wood frames. This is why steel-framed homes incline to be more characteristic and bespoke.

Versatility and Customization

Contrasting wood, steel can be shaped into any form, making it one of the most appealing materials in the building industry. This capability to shape into any form permits designers to represent their stormiest imaginings. As a result, its functions are immeasurable, from houses to skyscrapers!

Even though steel frames are manufactured offsite to requirements, they can be tailored and adapted for superior functionality. The frame is just the construction that leaves you with the remainder of the building to adapt to your requirements. You can even utilize a steel frame structure and syndicate it with bricks.

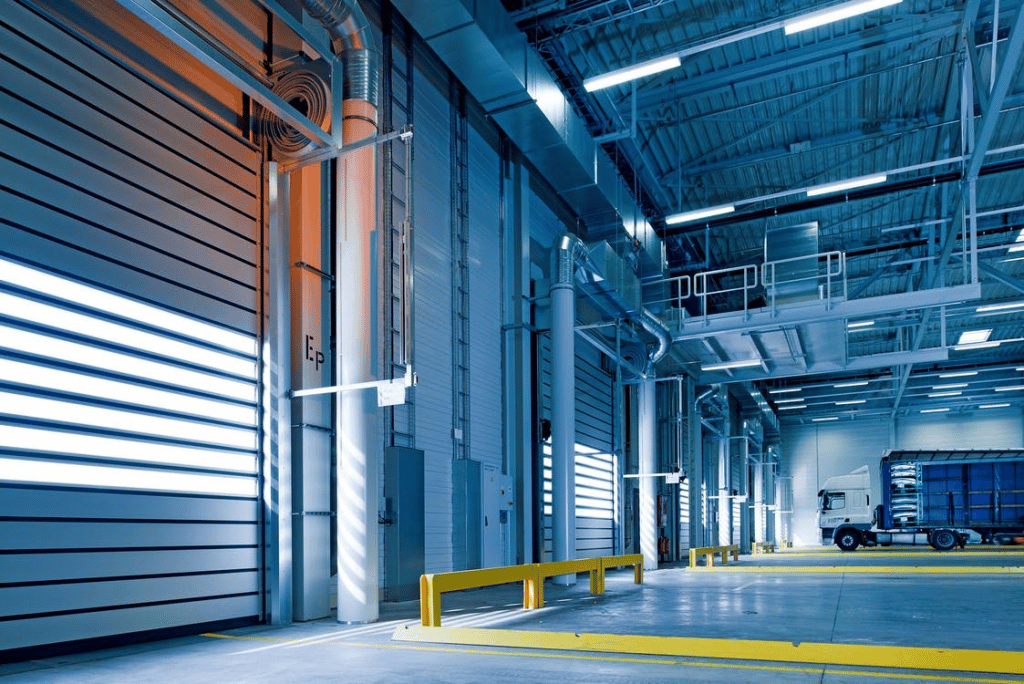

Why a Steel Frame Home the Best Choice

Even though steel frame homes have a few disadvantages, such as poor insulation, they make up for these shortcomings by being sturdier and more hard-wearing than wood. The addition of superfluous insulation can improve poor insulation. The short-term prices of expending steel frame vs. wood frame are nearly no different.

Conversely, using steel frames might vary depending on the additional supplies required. Long-term expenditures are lesser since you only have to fear insulation and corrosion. On the other hand, you have to put up with sophisticated insurance fees, deforming, decay, natural disaster destruction, and termite infestation with wood.

Steel frame homes are unquestionably better and simpler to change the structure. Therefore steel should be your number one choice!

Recommended Reading

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.