Application Of Steel Structure Platform

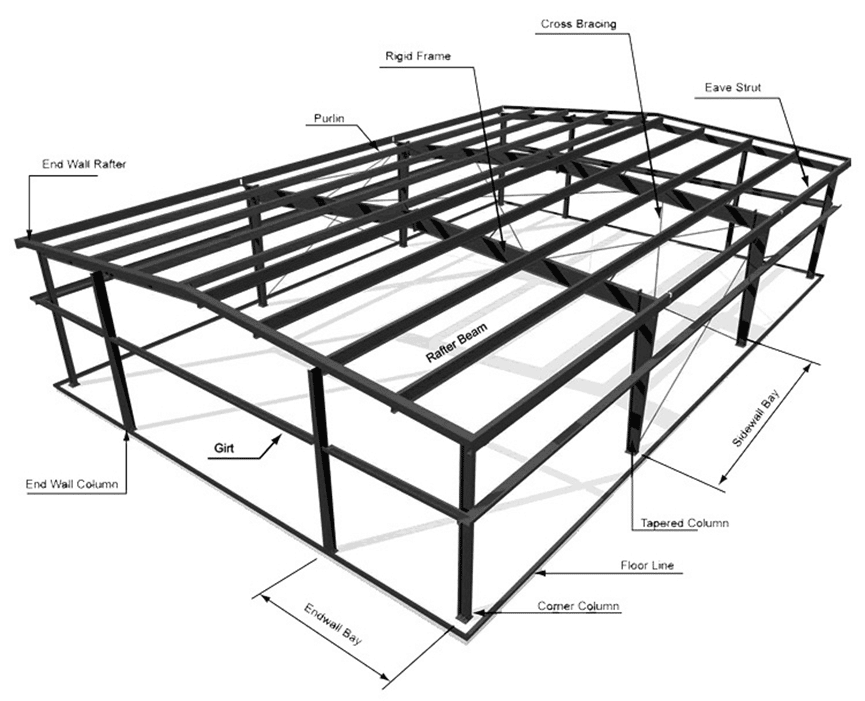

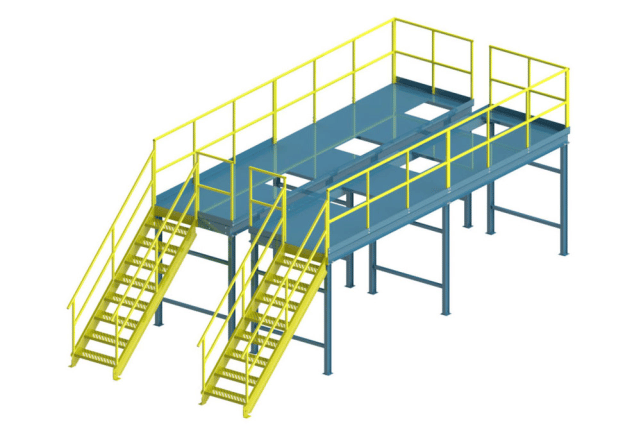

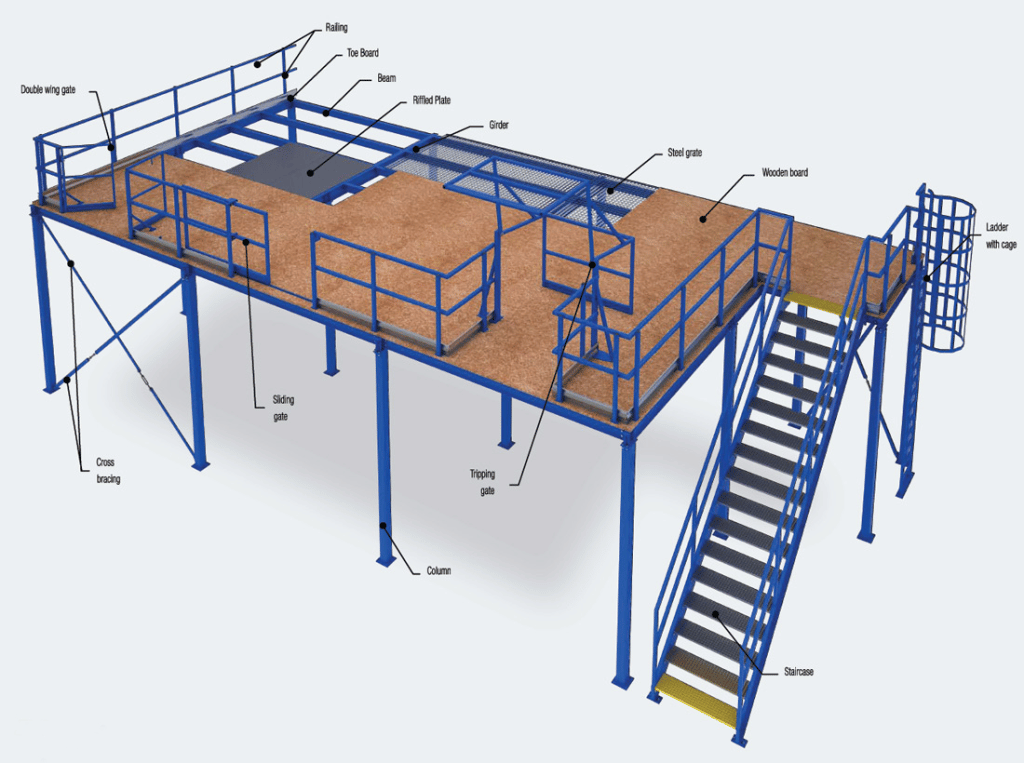

The steel structure platform is also known as a steel working platform. It is usually composed of planks, primary and secondary beams, columns, inter-column supports, as well as ladders, railings, etc. PEB steel structure platforms have a variety of structures and functions.

Because the steel structure platform is a fully assembled structure with flexible designs, it can be designed and manufactured according to different site conditions to meet site requirements, functional requirements, and logistics requirements.

Further Reading: Steel Building Plans and Specifications

Composition And Classification Of The Steel Structure Platform

Composition Of Steel Structure Platforms

The steel structure platform is a widely used working platform in modern warehouse storage. Most of this kind of steel structure platform is composed of beams, columns, plates, and other plate parts made of section steel and steel plate and the gaps between each part are connected by small parts such as welds, screws, or rivets(Structural Steel Welding).

Classification Of Steel Structure Platforms

According to usage performance

According to the performance, the working platform of steel structure processing can be divided into the production auxiliary platform and the production operation platform. Among them, the production operation platform can be divided into a medium platform and a heavy platform.

In addition, the steel structure working platform can also be divided into static load-bearing platforms and dynamic load-bearing platforms according to the type of load.

According to the size of the load classification

According to the size and nature of the load, the steel structure working platform can be divided into:

- Light platform, whose load design value is generally around q=2.0KN, is often used as production operation platform, observation platform, and sampling platform, pedestrian walkway, etc.

- Common operating platforms, whose load design value is generally around q=4.0~8.0KN, are often used as platforms for overhauling mechanical equipment and operating platforms for storing materials;

- Heavy-duty operating platforms, whose load design value can generally reach q=10.0KN or more, are often used in workshops with high load capacity requirements, such as steel-making workshop operating platforms, steel-rolling workshop soaking furnace platforms, etc. In addition, heavy-duty operating platforms are also used in work environments with traffic or vibration loads.

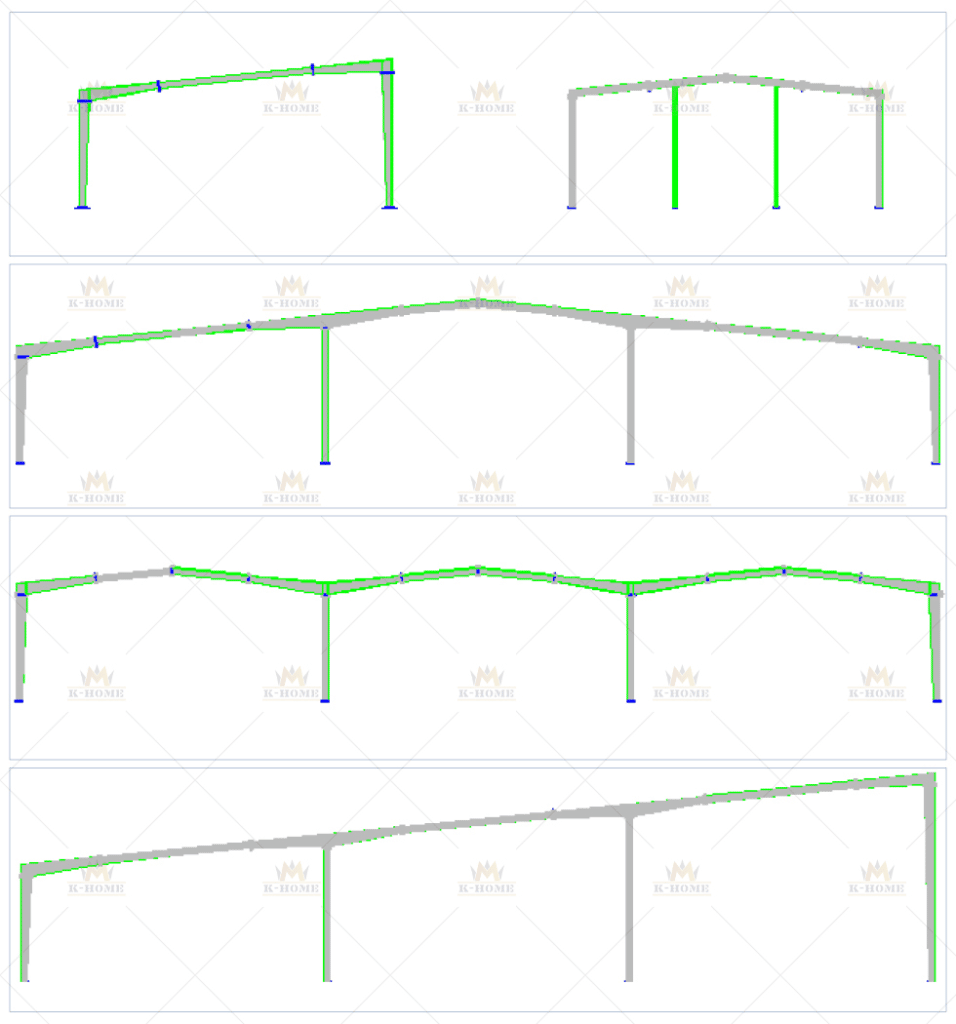

According to the support method of the bearing

According to the support method of the bearing, the steel platform can be divided into:

The two ends of the platform beam are directly supported on the wall of the plant column or the platform on the corbel, which not only expands the production space but also saves steel;

One end of the platform beam is supported on the workshop corbel or other load-bearing wall, and the other end is supported on an independent platform column. This kind of platform can be flexibly arranged according to the change in production process, and has been widely used;

Both ends of the platform are supported on the platform column, and the platform column is supported on the floor or foundation, the platform can ensure its own stability, and can meet the production process requirements, and is widely used;

An independent working platform for steel structure processing, its platform beam and platform bracket is directly supported by the production equipment. This platform not only saves steel, but also has the advantages of light structure, flexible use and beautiful appearance, and has been widely used.

Arrangement Of Steel Structure Platform

Confirm the plane size, elevation, beam grid, and column grid of the steel structure platform. When designing, not only must meet the requirements of normal use and operation, but also consider the equipment load on the platform and the location of other large concentrated loads, and the hanging of large-diameter industrial pipelines in the position of beams and columns;

The installation of the steel structure platform should be economical and reasonable, and the force transmission should be direct and clear. The placement of the beam grid should be adapted to its span. When the span of the beam is large, the spacing should also be increased. Make full use of the allowed span of the plank, and arrange the beam grid reasonably to obtain better economic results.

The installation of the steel structure platform should meet the requirements of workers operating on the steel structure platform, and ensure the safety and convenience of the passage and operation of the workers.

Generally, the clear height should not be less than 1.8m, protective railings should be set around the platform, and the height of the railings is generally 1m. When the height of the workbench is greater than 2m, it is also necessary to set up skirting boards under the protective railings. The workbench also needs to be provided with ladders for up and down passages.

Further Reading: Steel Structure Installation & Design

Features Of Steel Structure Platform:

- Diverse structures and functions

- Short construction period, cost-saving, time-saving and labor-saving

- It is usually composed of beams, columns, plates, and other components made of section steel and steel plate

- Fully assembled structure, flexible design, widely used in modern storage

Further Reading(Steel Structure)

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.