PEB Structure | Pre-Engineered Building Solutions

What is a PEB structure?

PEB Structure stands for Pre-Engineered Building. It is an innovative construction system. All components are precision-designed and fabricated in a factory, then transported to the site for rapid assembly. This method optimizes material usage and construction efficiency. It is particularly suited for industrial buildings.

PEB Structure construction Procedure | 3D PEB Construction animation

- steel warehouse building

- steel workshop building

- PEB structure

- PEB steel structure

Steel Structure vs. RCC (Reinforced Concrete) Buildings

|

Items |

Steel Structures |

RCC Buildings |

|---|---|---|

|

Construction Costs |

· Optimized design reduces steel consumption · Standardized production lowers manufacturing costs · Simpler foundation requirements save on civil engineering costs |

· High demand for materials and on-site labor |

|

Construction Speed |

Foundation construction and steel structure prefabrication are carried out simultaneously, resulting in faster progress. |

Due to the slow speed of on-site pouring and curing. |

|

Design flexibility |

· Easily customizable span, height, and layout to meet specific functional requirements · Relatively easy to expand or relocate in the future. |

Once built, the layout is almost impossible to change |

|

Quality and Durability |

Core components are manufactured in a controlled factory environment, ensuring high precision and consistent quality. |

The quality is greatly affected by the worker’s skill level, material ratio, and maintenance conditions, and is prone to quality problems such as cracks. |

|

Environmental Impact |

The steel is 100% recyclable. Construction waste is minimal, with little impact on the surrounding environment. |

It generates a large amount of construction waste, and the concrete is difficult to recycle after demolition, so it is mostly disposed of by landfill. |

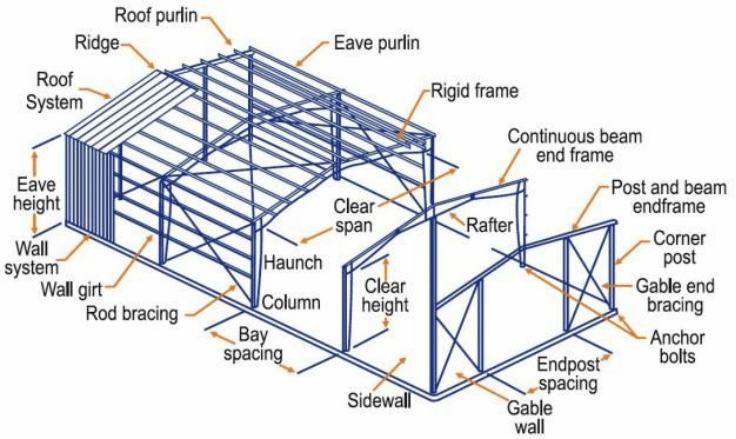

The Key Components of PEB Structure

The PEB system achieves low construction costs, short project cycles, and high-quality buildings through optimized component design, efficient factory prefabrication, and rapid on-site assembly.

The PEB steel structure system mainly comprises the following three types of precisely designed components:

Primary members

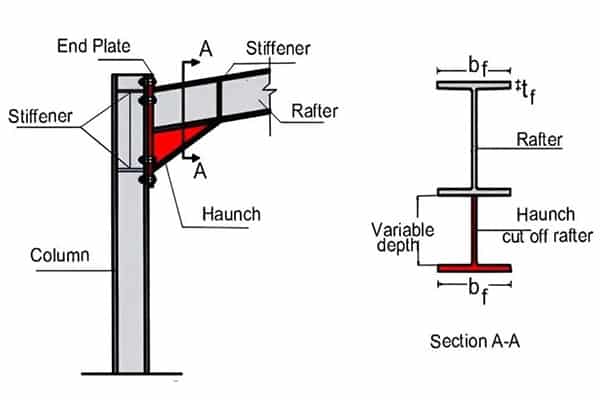

The main steel frame forms the main columns and rafters, serving as the building’s “skeleton” and bearing the core load. It is constructed of high-strength H-beams and features a multi-segment structure. The main steel frame design typically features clear spans or multiple spans, with tapered or straight profiles. K-HOME uses steel that meets GB Chinese standards and has international compatibility.

- H beam

- steel columns

- steel rafters

- Connection between steel columns and steel rafters

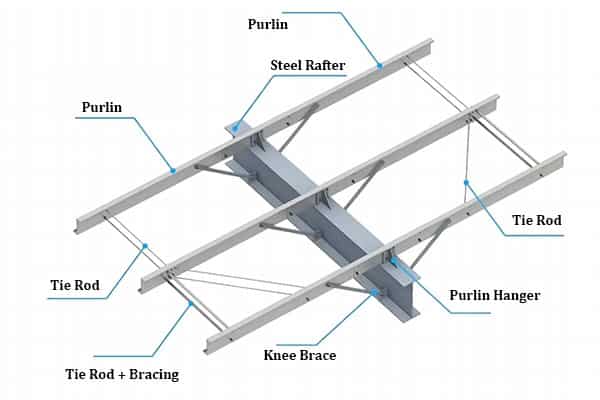

Secondary Members

Utilizing cold-formed Z-shaped and C-shaped steel, this structure serves as purlins, wall beams, etc., supporting the roofing layer and transferring loads to the main structure.

- Z type purlins

- c type purlins

- steel component connection for the Roof

- steel component connection for the Roof

Cladding Layer

Made of roll-formed steel sheets, this layer serves as the roof and walls, providing enclosure functionality and can be integrated with insulation layers as needed. Insulation materials include polyurethane, fiberglass, or rock wool to improve energy efficiency and thermal comfort.

- color steel plate

- sandwich panel – roof panel

- Common Color Option of Color Steel Sheet

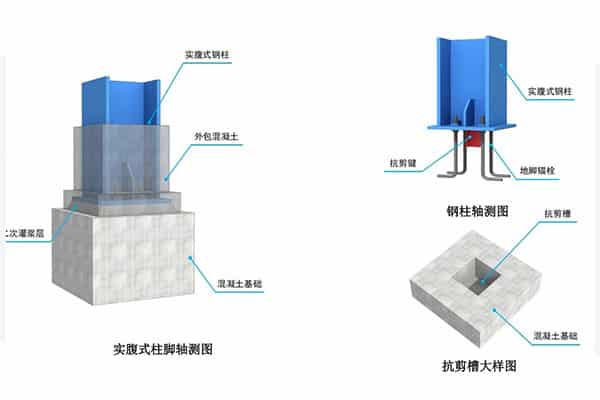

Foundation Connections

Embedded parts: Key fasteners in concrete foundations.

Column base joints: Hinged connections only transmit vertical forces, while rigid connections can transmit bending moments.

| Component Structure | Material | Technical Parameters |

|---|---|---|

| Main Steel Structure | GJ / Q355B Steel | H-beam, Customized height according to building requirements |

| Secondary Steel Structure | Q235B; Paint or Hot Dip Gavalnized | H-beam, Spans range from 10 to 50 meters, depending on design |

| Roof System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to design |

| Wall System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to wall area |

| Window & Door | Color steel sliding door / electric rolling door Sliding Window | Door and window sizes are customized according to design |

| Fireproof Layer | Fire retardant coatings | Coating thickness (1-3mm) depends on the fire rating requirements |

| Drainage System | Color Steel &PVC | Downspout: Φ110 PVC Pipe Water Gutter: Color Steel 250x160x0.6mm |

| Installation Bolt | Q235B Anchor Bolt | M30x1200 / M24x900 |

| Installation Bolt | High-Strength Bolt | 10.9M20*75 |

| Installation Bolt | Common Bolt | 4.8M20x55 / 4.8M12x35 |

Different Types of Pre-Engineered Buildings

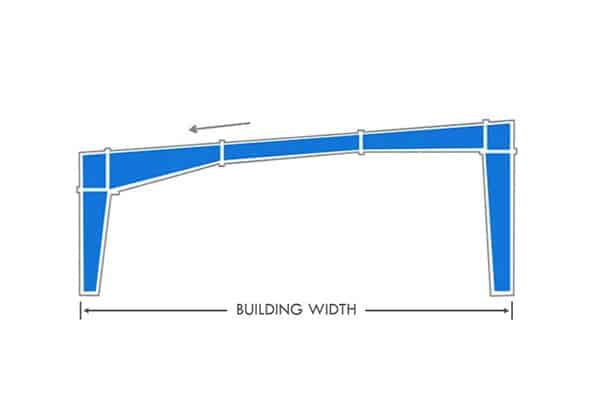

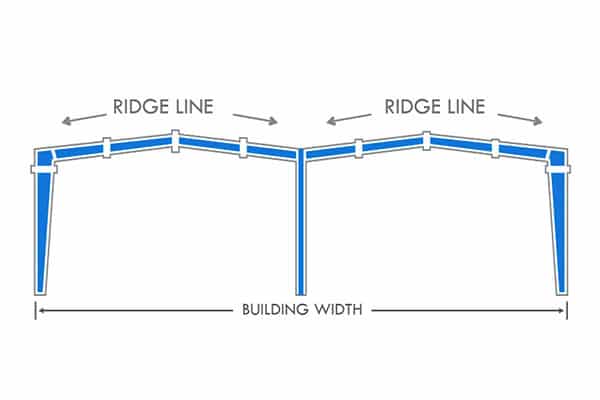

Based on functional requirements and span specifications, three typical structural systems are primarily adopted:

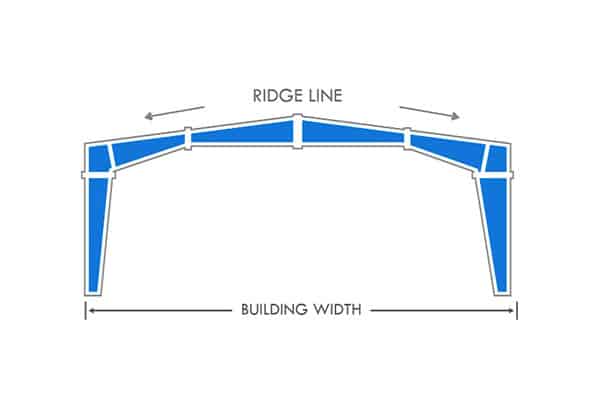

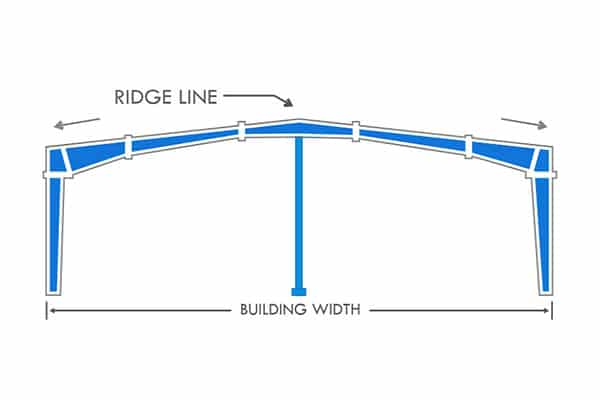

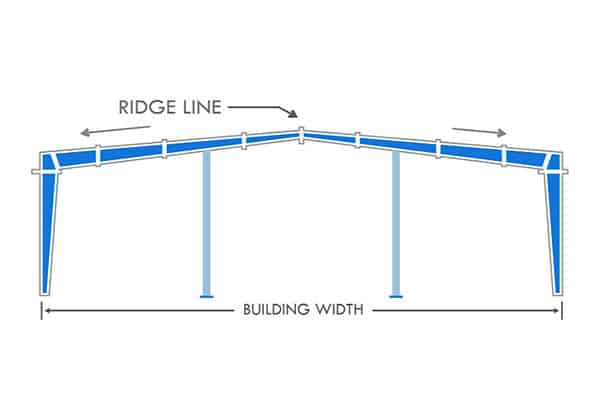

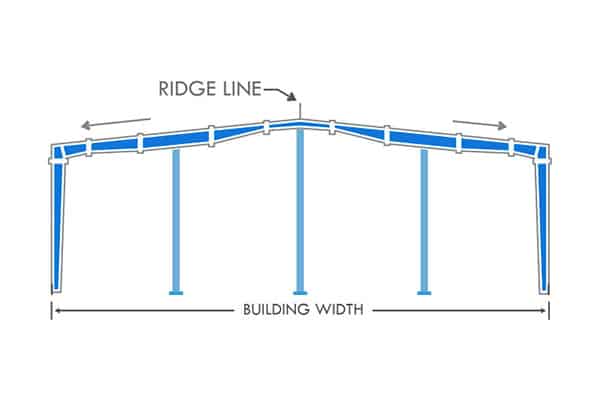

1. Portal Frame System: The mainstream structural form for single-story factory buildings. Columns and beams are rigidly connected to form a “portal”-shaped frame. Specifically, it is divided into three typical configurations: Basic type (without crane) Crane-equipped type (with crane beam system) Partial two-story type (additional floors or mezzanines in some areas)

2. Multi-story Frame System: Suitable for high-rise or large-span requirements. Mainly divided into three categories: Pure rigid frame (rigid connection in both longitudinal and transverse directions) Rigid-braced hybrid system (transverse rigid connection + longitudinal bracing) Fully braced frame (fully hinged + bracing system) Column cross-sections can be H-shaped, box-shaped, etc.

3. Special Derivative Forms: Gable frame: Column cross-section rotated 90 degrees for special design. Steel truss structure: Axial force on members, span can reach over 100 meters. Space frame/shell structure: Flat or curved grid, suitable for large-space roofs.

Khome prefers portal frame systems and has extensive project experience in this field, with project cases in multiple countries worldwide.

About K-HOME & PEB Services

——Pre Engineered steel Building Manufacturers China

Henan K-home Steel Structure Co., Ltd is located in Xinxiang, Henan Province. Established in the year 2007, registered capital of RMB 20 million, covering an area of 100,000.00 square meters with 260 employees. We are engaged in prefabricated building design, project budget, fabrication, installation of steel structure and sandwich panels with second-grade general contracting qualification.

Design

Every designer in our team has at least 10 years of experience. You don’t have to worry about the unprofessional design affecting the safety of the building.

Mark and Transportation

In order to make you clear and reduce the site work, we meticulously mark each part with labels, and all parts will be planned in advance to reduce the number of packings for you

Manufacturing

Our factory has 2 production workshops with large production capacity and short delivery time. Generally, the lead time is around 15 days.

Detailed Installation

If this is the first time for you to install the steel building, our engineer will customize a 3D installation guide for you. You don’t need to worry about the installation.

why K-HOME Steel building?

As a professional PEB manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

Applications of Our PEB Steel Structure

Prefabricated steel structure buildings have become the first choice for modern industrial buildings due to their advantages such as high strength, fast construction, flexible space, environmental protection and energy saving, and are widely used in many scenarios.

Manufacturing and Industrial Plants

PEB steel structure buildings are essential facilities in modern manufacturing. They securely store raw materials, semi-finished products, and finished goods. Their robust structure easily supports heavy machinery and tall racking.

But their real advantage lies in flexibility. Our designed steel warehouse& workshop integrates your production lines and storage areas within a column-free space. This creates a smooth workflow. It reduces material handling, simplifies operations, and increases efficiency.

K-HOME Pre-engineered Steel Warehouse for clear span industrial plant clear span industrial plant interior Pre-Engineered Steel Warehouse for CNC Plant Interior of a Mutil span steel CNC plant

Logistics and Distribution Centers

PEB structure are ideal for logistics and distribution warehouse. Because they provide the large, open space you need. These clear-span buildings have no internal columns getting in the way.

This open layout makes it easy to organize goods. Forklifts and trucks can move and turn freely, which speeds up loading and unloading. This means you can move more goods in less time, which is the main goal of any distribution business.

Retail and Bulk Storage Superstores

PEB steel buildings are a safe and strong choice for retail and bulk storage. They are built to handle heavy loads and protect your goods from harsh weather. Because steel is fire-resistant, it adds a critical layer of safety for your inventory. This makes a steel building a reliable and ideal solution for securing your products, whether you run a retail store or a large storage facility.

Agriculture and Special Construction

Pre engineered buildings are ideal for agricultural Construction. They are commonly used as warehouses and granaries for storing agricultural machinery and grain. These buildings can also serve as wholesale markets for agricultural products. Their spacious, open layout and robust, durable design meet the needs of modern agricultural product sales.

peb steel structure solutions from K-HOME

PEB steel structure design is a core aspect of building engineering, directly impacting a building’s safety, stability, and cost-effectiveness. At K-HOME, we base our work on Chinese GB standards, combined with international engineering concepts, ensuring high-standard structural performance and broad adaptability for every project.

We understand that different countries and regions have their own regulatory requirements. If your project requires strict adherence to local standards (such as US ASTM or European EN standards), we can leverage our extensive international project experience to provide structural design solutions that comply with local regulations.

To date, K-HOME’s prefabricated steel structure buildings have been successfully implemented in numerous countries and regions worldwide, including African markets such as Mozambique, Guyana, Tanzania, Kenya, and Ghana; the Americas such as the Bahamas and Mexico; and Asian countries such as the Philippines and Malaysia. Familiar with diverse climatic conditions and approval systems, we can provide you with steel structure solutions that combine safety, durability, and economy.

prefabricated steel warehouse with office in Mozambique

Pre-Fabricated Warehouse in Saint Vincent and the Grenadines

PEB Steel Buildings in the Philippines

Steel furniture shop building in Bahamas

why K-HOME Steel building?

As a professional PEB manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

related blogs

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.